- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

xinhe

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

2200X800X1700MM

-

Power (kW):

-

37

-

Weight:

-

4800 KG

-

After-sales Service Provided:

-

Online Support

-

Raw material:

-

PVC Powder

-

Keywords:

-

PVC BOARD MAKING

-

Product name:

-

PVC Board Production Line

-

Inverter:

-

TECO Brand

-

Automatic Grade:

-

Fully Automaitc

-

Product Type:

-

Pvc Profile Extrusion Machine

-

Function:

-

Profile Producing

Quick Details

-

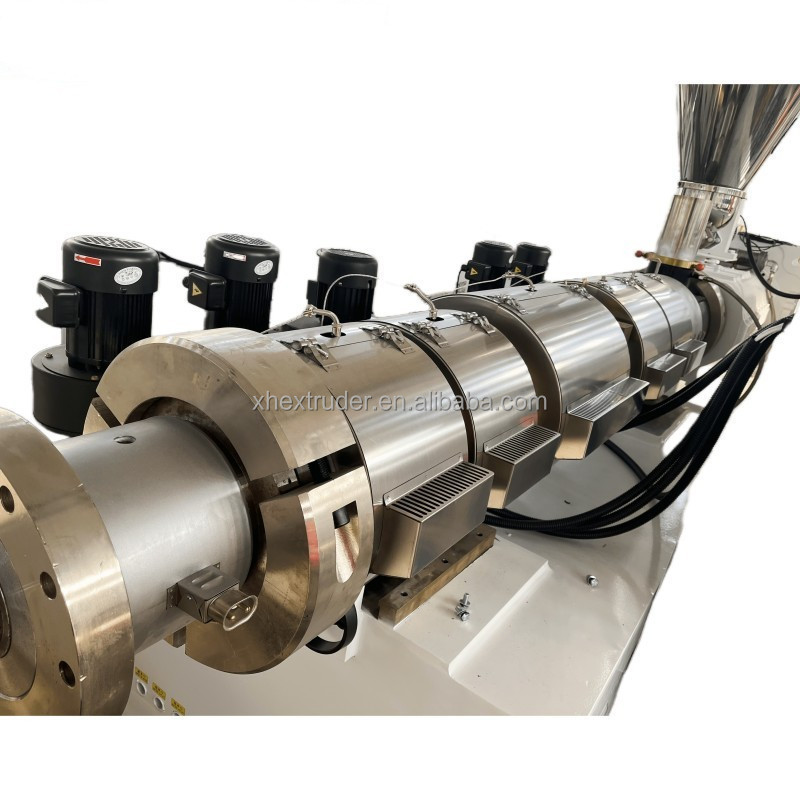

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

25:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

xinhe

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

2200X800X1700MM

-

Power (kW):

-

37

-

Weight:

-

4800 KG

-

After-sales Service Provided:

-

Online Support

-

Raw material:

-

PVC Powder

-

Keywords:

-

PVC BOARD MAKING

-

Product name:

-

PVC Board Production Line

-

Inverter:

-

TECO Brand

-

Automatic Grade:

-

Fully Automaitc

-

Product Type:

-

Pvc Profile Extrusion Machine

-

Function:

-

Profile Producing

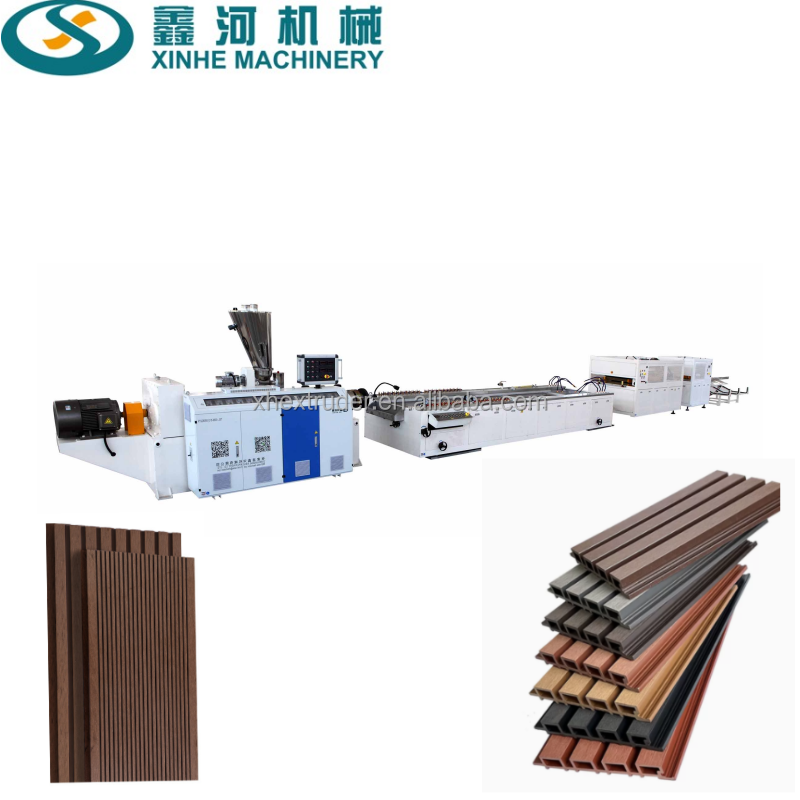

Overview

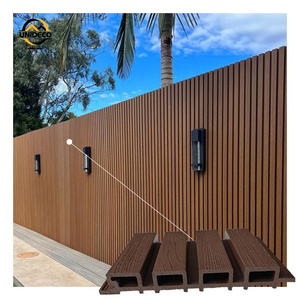

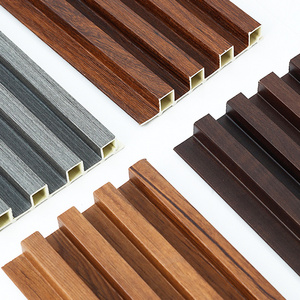

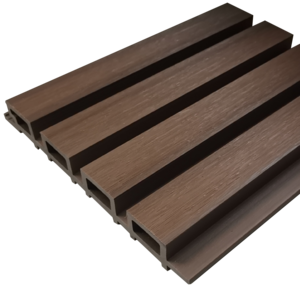

WPC Wall Panel Cladding Panel

Wood-plastic interior doors, baseboards, integral cabinets, closets, exterior wall panels, ceiling ceiling, decorative wall panels, outdoor floors, guardrail posts, plastic steel pavilions, garden guardrail, balcony guardrail, perimeter fence, leisure benches, tree pools, flower shelves, flower box air conditioning racks, air conditioning shields, blinds, road signs, transportation pallets, etc.

FEATURES AT A GLANCE

The products can be Waterproof, moisture-proof, insect-proof, termite-proof, effectively eliminate insect harassment, prolong the service life of colorful, many colors to choose from. Strong plasticity.

Good sound absorption effect, good energy saving。

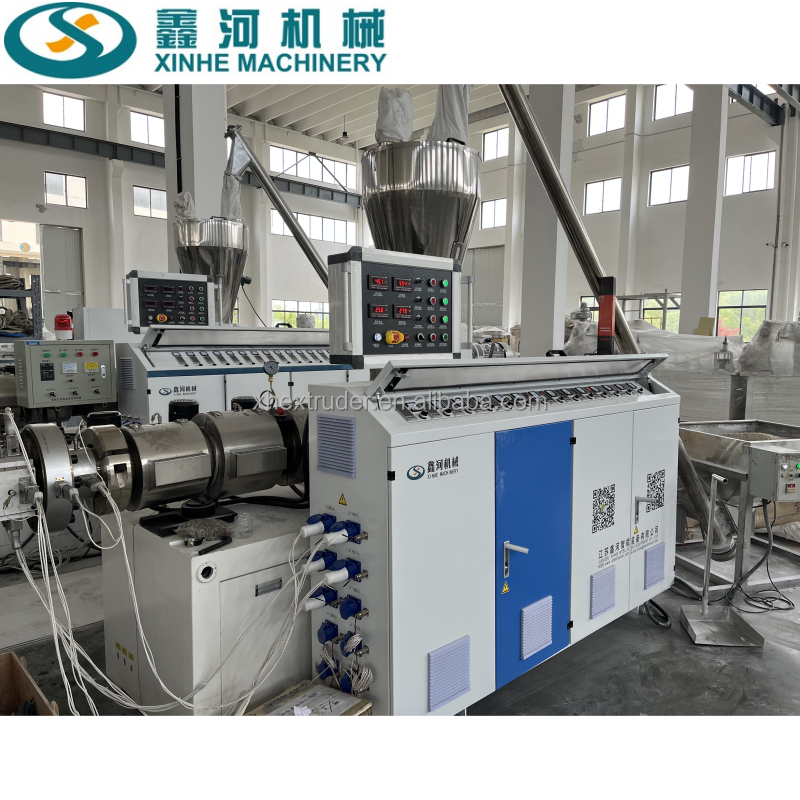

Front extruder

Left extruder

Whole Barrel

Main Technical Parameters

|

Model

|

SJSZ-51/105

|

SJSZ-65/132

|

SJSZ-80/156

|

|

Max production width

|

200mm

|

250mm

|

600mm

|

|

Extruder capacity

|

100-120kg/h

|

150-180kg/h

|

250-380kg/h

|

|

Main motor power

|

22kw

|

37kw

|

75kw

|

Production process

Production flow of PP/PE WPC profile:

1. plastic recycling: washing, crushing ,drying the PP/PE plastic wastage into flakes, the flakes shall be used for WPC production directly.

2. wheat straw powder making: crushing, milling and drying the wheat straw into 80-100 mesh powder

3. material mixing: weighting and mixing all material together according to our formula by hot mixing machine

4. WPC granulating: extrusion by parallel double screw extruder and do hot-pelletizing into WPC granules.

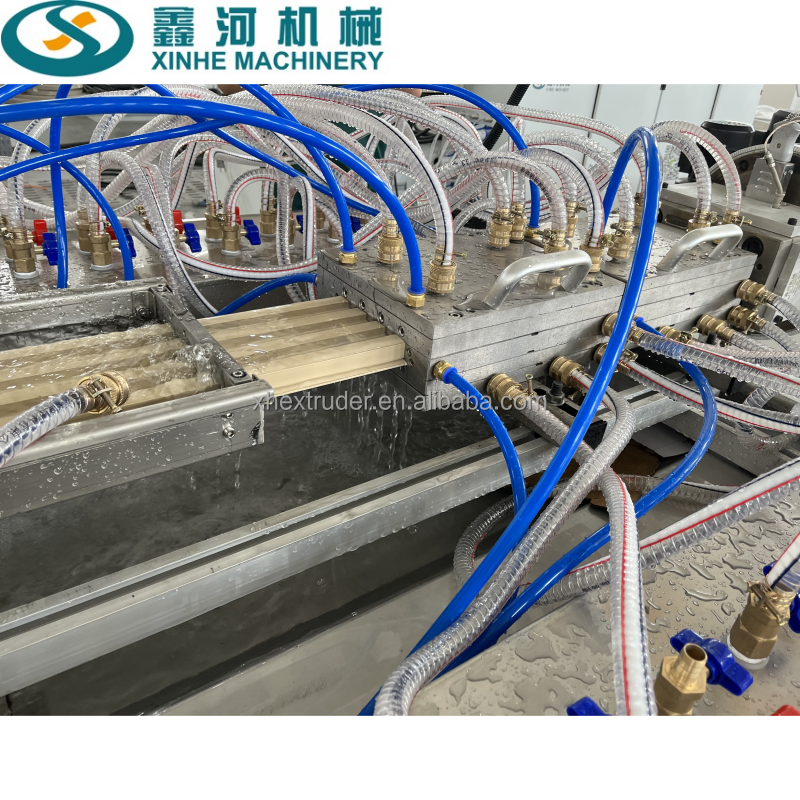

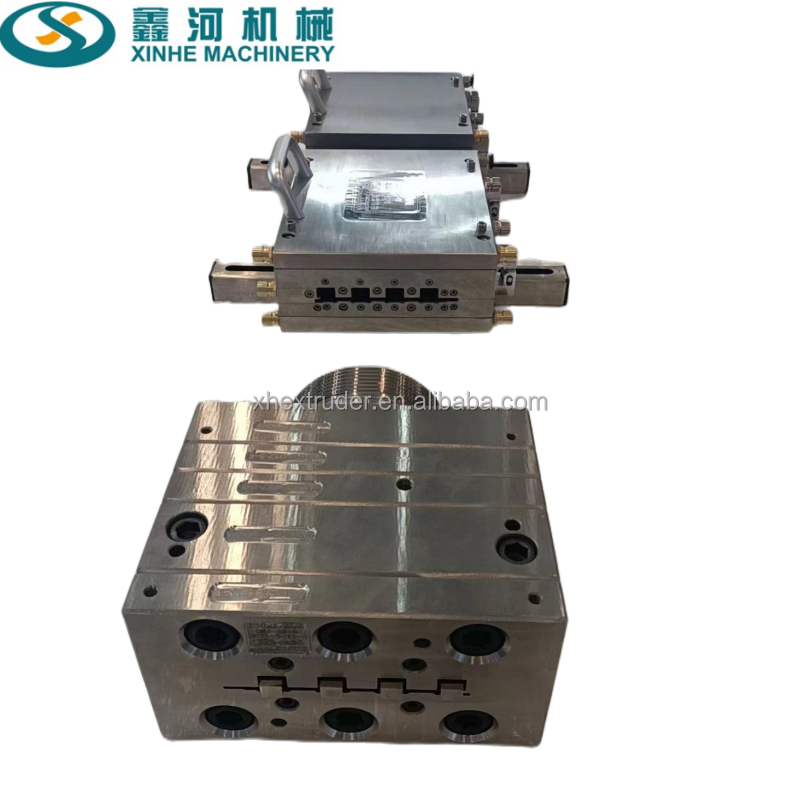

5. WPC extrusion: extrusion by conical double screw extruder and molding in required size and shape with water cooling

calibrating, online fixed length cutting.

6. WPC surface design: embossing, brushing, or sanding on the surface to make different wooden grain feeling.

1. plastic recycling: washing, crushing ,drying the PP/PE plastic wastage into flakes, the flakes shall be used for WPC production directly.

2. wheat straw powder making: crushing, milling and drying the wheat straw into 80-100 mesh powder

3. material mixing: weighting and mixing all material together according to our formula by hot mixing machine

4. WPC granulating: extrusion by parallel double screw extruder and do hot-pelletizing into WPC granules.

5. WPC extrusion: extrusion by conical double screw extruder and molding in required size and shape with water cooling

calibrating, online fixed length cutting.

6. WPC surface design: embossing, brushing, or sanding on the surface to make different wooden grain feeling.

embossing

shaping

tractor

product

PRODUCT CONFIGURATION

These are normal specification,we can also customize for our customers. It includes 219*26mm; 148*21mm;156*21mm.

Product application

Hot Searches