- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Industrial Profile

-

Type:

-

IGBT Induction Heating

-

Usage:

-

brazing

-

Color:

-

Customer's Requirement

-

Feature:

-

99 % High Purity

-

Advantage:

-

High Speed Low Noise

-

Voltage:

-

380V 50-60hz

-

Power:

-

30kw

-

Capacity:

-

400-600kg/h

-

Processing Material:

-

Flat Iron

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

FOXING FURNACE

-

Weight (KG):

-

2500

-

Application:

-

Industrial Profile

-

Type:

-

IGBT Induction Heating

-

Usage:

-

brazing

-

Color:

-

Customer's Requirement

-

Feature:

-

99 % High Purity

-

Advantage:

-

High Speed Low Noise

-

Voltage:

-

380V 50-60hz

-

Power:

-

30kw

-

Capacity:

-

400-600kg/h

-

Processing Material:

-

Flat Iron

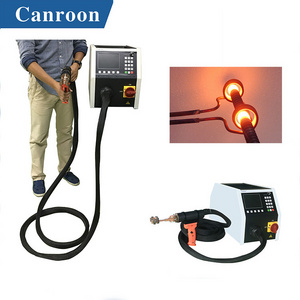

Factory price induction heating brazing welding machine,portable induction heater, 10KW,10-50 KHZ

high frequency induction heating machine is a device adopt for modern electronic module as key part of converter, through convert 50/60Hz power current into current with at different frequency band, which produces strong electromagnetic field in inductor to heat metal in a very short time. it can widely used in hardening, brazing, forging, melting, annealing, and some other industrial metal heating process.

Advantages of high frequency induction heater

1. The machine adopts IGBT modules (Siemens, Germany), high efficiency, energy saving.

2. Environmental. Almost no oxide layer, produced no exhaust, no waste-water is generated.

3. Heating fast and uniform.

4. A unique cooling circulation system, ensure that the equipment 24 hours of continuous work.

5. Easy installation, simple operation.

6. Safe and reliable. No high voltage, very safe for operating people.

7. Machine power can be adjust step-less.

8. It has complete self-protect functions: such as many types of alarm lamps: over-current, over-voltage, over hot, water shortage etc, can also control and protect itself.

| Equipment type | WZP-60 | WZP-90 | WZP-120 |

| oscillation frequency | 15-30KHZ | 15-30KHZ | 15-30KHZ |

| Input voltage | 320-420V | 320-420V | 320-420V |

| continuous load rate | 90% | 100% | 100% |

| Input current | 3-60A | 4-90A | 6-120A |

| Colling pressure | 0.2Mpa | 0.3Mpa | 0.3Mpa |

| machine weight | 50kg | 63kg | 65kg |

| Machine volume | 580x340x580mm | 660x400x480mm | 660x400x580mm |

High frequency Induction heaer machine mainly used for forging,hardening, annealing, tempering, brazing, melting for many kinds of metal materials, such as auto parts workpieces, pipes, tubes, wires, rebars, motorcycle parts, camshaft, crankshaft, gear, axles, sprockets, etc. According to specifications of your workpiece requirement, we will offer you the best suitable machine.

1, forging, hot forming

A, all kinds of standard parts, fasteners, machinery parts, hardware tools, straight shank twist hot upsetting, hot.

B, metal heat annealing. Such as: tensile steel tube, pipe, smashed head; wire, heating wire nail; stainless steel annealed, rose type.