- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

500-033-5

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

Fastfix-it

-

Model Number:

-

FX-5003

-

Type:

-

resin glue

-

Material:

-

epoxy resin

-

Ratio:

-

3:1

-

Finish color:

-

clear/ transparent

-

Shelf life:

-

24 months

-

Gel time:

-

75~100 min

-

Curing time:

-

24~48 hr

-

Hardness Shore D:

-

85

-

BISPHENOL A:

-

n.d

-

PHENOL:

-

n.d

Quick Details

-

CAS No.:

-

Mixture

-

Other Names:

-

Liquid resin

-

MF:

-

Mixture

-

EINECS No.:

-

500-033-5

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

Fastfix-it

-

Model Number:

-

FX-5003

-

Type:

-

resin glue

-

Material:

-

epoxy resin

-

Ratio:

-

3:1

-

Finish color:

-

clear/ transparent

-

Shelf life:

-

24 months

-

Gel time:

-

75~100 min

-

Curing time:

-

24~48 hr

-

Hardness Shore D:

-

85

-

BISPHENOL A:

-

n.d

-

PHENOL:

-

n.d

Product Description

|

Production Name:

|

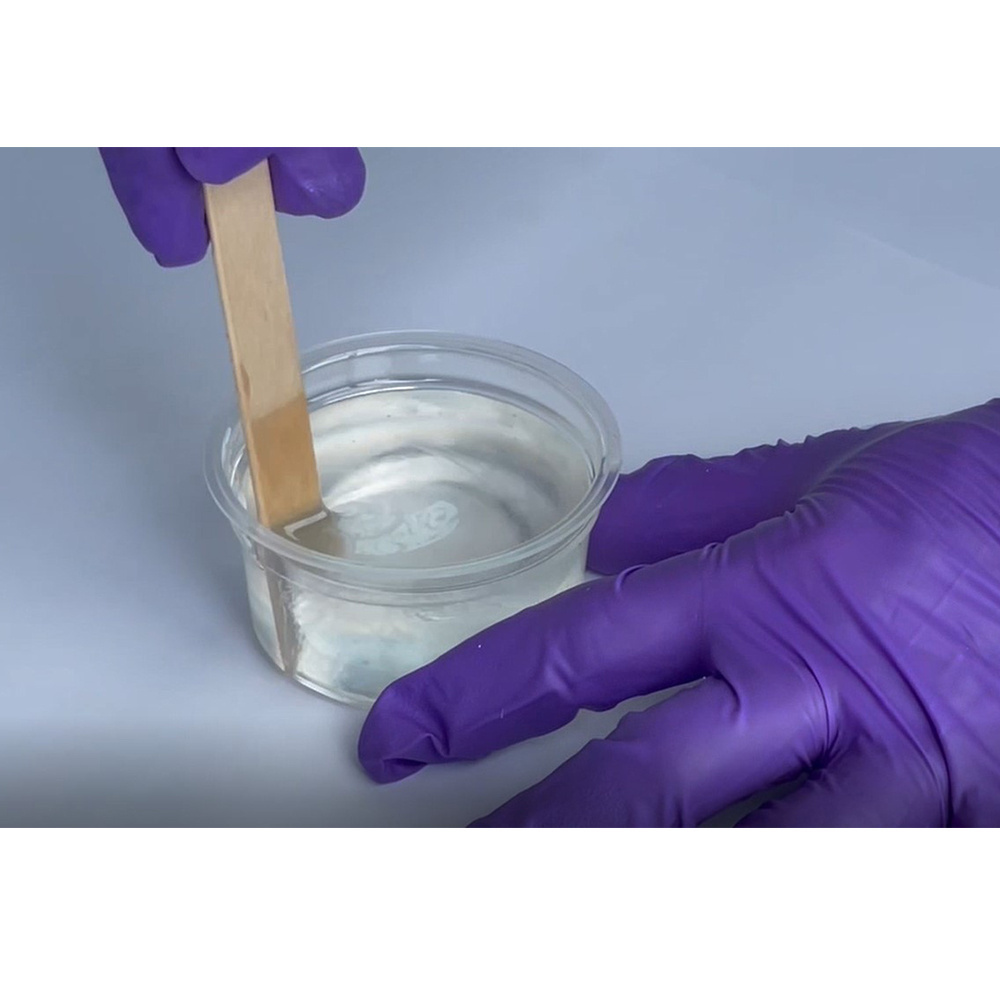

CRYSTAL GLUE RESIN

|

|

Product Code:

|

FX-5003

|

|

Product Description:

|

Use our clear epoxy resin for all of your casting and coating applications. Cures crystal clear and hard as a rock. Can be used as

either a coating for tables, bars, wood, canvas paintings, etc. or cast in a suitable mold. |

|

Features:

|

1. Odor free, Voc free, BPA free

2. UV Resistant |

Application:

・Set up: Find a well-ventilated, dust free area to set up your resin pour. The temperature should also be mild (in the 70s or 80s) for best results. Lay down a plastic drop cloth to protect your table and / or floor. You should also have rubber gloves, protective eye wear, paper towels, mixing sticks (wood and plastic work well), plastic cups for mixing, measur ing cups (optional), and your prepared mold (optional), a foam brush (for table coatings only) and lacquer thinner (for clean up).

・

Keep in mind; it’s always bet ter to have a little extra resin left over than it is to have to mix up an other batch of it mid project.

・

Pour equal parts resin and hardener into two cups and then pour those two cups into a third mixing cup.

・ From here you should quickly pour your resin into your mold, onto your canvas or table, etc. Cover your work with a drop cloth, plastic bin, cardboard box etc. to keep dust off. Come back in 5 minutes to check for air bubbles and if necessary, use a torch or heat gun on low in a sweeping motion about 8 inches from the resin top of the bubbles. For smaller castings, bubbles can be popped with a toothpick.

・ From here you should quickly pour your resin into your mold, onto your canvas or table, etc. Cover your work with a drop cloth, plastic bin, cardboard box etc. to keep dust off. Come back in 5 minutes to check for air bubbles and if necessary, use a torch or heat gun on low in a sweeping motion about 8 inches from the resin top of the bubbles. For smaller castings, bubbles can be popped with a toothpick.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Searches