Step

❶

: Material Feeding

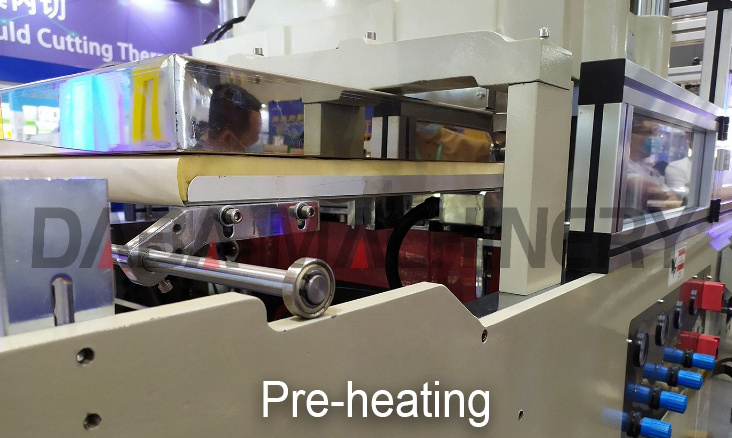

Step

❷

: Pre-heating

- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

10-25 cycles /minutes

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 1 mm

-

Heating Power (kW):

-

38 kW

-

Air Comsumption(L/min):

-

2000 L/min

-

Water Comsumption(L/min):

-

15 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

Voltage:

-

AC380V±15V,50/60HZ

-

Dimension(L*W*H):

-

6590x1760x2720mm

-

Weight (T):

-

6.8 T

-

Power(KW):

-

38kw

-

Feeding method:

-

servo motor

-

Function:

-

In-mould Cutting

-

Certification:

-

CE

-

Forming Method:

-

positive pressure

-

Finished Products:

-

Bakery Tray

-

Power Consumption:

-

14kw/h

-

Knife Length:

-

APET:12000mm / OPS:18000 mm

-

Material Roll Diamete:

-

1000 mm

-

Sheet Width:

-

1000 mm

Quick Details

-

Max.Forming Height(mm):

-

125 mm

-

Forming Width (mm):

-

700 mm

-

Forming Length (mm):

-

950 mm

-

Production Speed(Cycles/min):

-

10-25 cycles /minutes

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 1 mm

-

Heating Power (kW):

-

38 kW

-

Air Comsumption(L/min):

-

2000 L/min

-

Water Comsumption(L/min):

-

15 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

Voltage:

-

AC380V±15V,50/60HZ

-

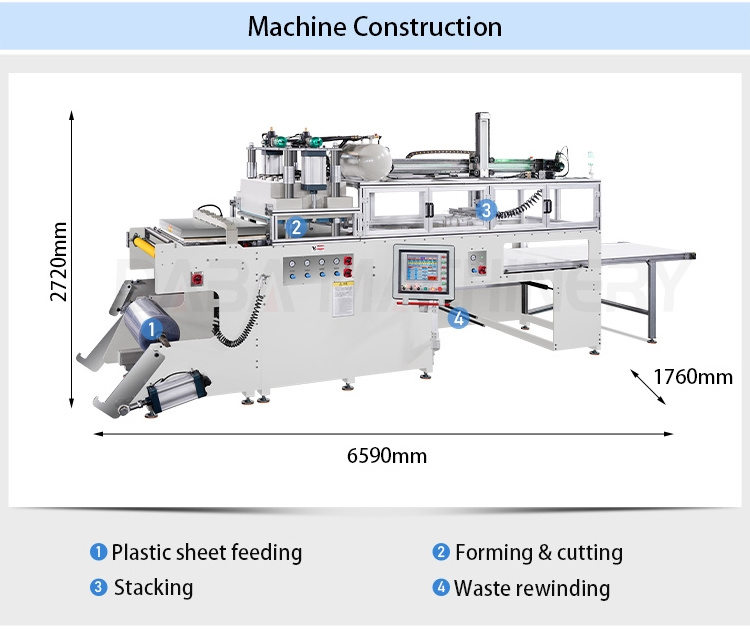

Dimension(L*W*H):

-

6590x1760x2720mm

-

Weight (T):

-

6.8 T

-

Power(KW):

-

38kw

-

Feeding method:

-

servo motor

-

Function:

-

In-mould Cutting

-

Certification:

-

CE

-

Forming Method:

-

positive pressure

-

Finished Products:

-

Bakery Tray

-

Power Consumption:

-

14kw/h

-

Knife Length:

-

APET:12000mm / OPS:18000 mm

-

Material Roll Diamete:

-

1000 mm

-

Sheet Width:

-

1000 mm

Product Description

Introduction :

DB-70/95 plastic thermoforming machine is suitable for forming HIPS, PS, BOPS, PVC, PET sheets. It can produces boxes, trays, fast food boxes, dishes,lids, cookies tray, mobile phone tray & other blister tray.

Advantages :

1.Combination of mechanical, electrical and pneumatic components, and it combines the material sending, heating, forming and cutting into one process. The machine with manipulator can stack plastic products.The final products already cut one by one.

2.The whole system is controlled a micro PLC, which can be operated in man-interface. And it is capability reliable, safe and jarless, less error.

3.Servo motor drives the sheet transport system.

4.Telecommuting and memory reserve functions.

5.Simple machine operation, smaller machine size compare with other thermoforming machines aslo have large forming area , low power consumption, .Has quickly production capacity, highly utilization ratios of plastic sheet, Low air consumption and maintenance,beautiful final products, so it is a new generation ideal package equipment.

DB-70/95 plastic thermoforming machine adopts the most advanced plastic thermoforming technology and was developed to be a forming machine of high production efficiency. It is a combination of mechanical, electrical and pneumatic components, and the whole machine is controlled by micro PLC. The machine has man-interface operation. Combines heating, forming, cutting into one process.

Advantages :

1.Combination of mechanical, electrical and pneumatic components, and it combines the material sending, heating, forming and cutting into one process. The machine with manipulator can stack plastic products.The final products already cut one by one.

2.The whole system is controlled a micro PLC, which can be operated in man-interface. And it is capability reliable, safe and jarless, less error.

3.Servo motor drives the sheet transport system.

4.Telecommuting and memory reserve functions.

5.Simple machine operation, smaller machine size compare with other thermoforming machines aslo have large forming area , low power consumption, .Has quickly production capacity, highly utilization ratios of plastic sheet, Low air consumption and maintenance,beautiful final products, so it is a new generation ideal package equipment.

|

Machine Parameter

|

|

|

||

|

No

|

Item

|

Data

|

||

|

1

|

Forming area

|

700*950mm

|

||

|

2

|

Forming depth

|

125mm

|

||

|

3

|

Sheet thickness range

|

0.15-1mm (0.006''-0.040'')

|

||

|

4

|

Sheet roller diameter

|

1000mm

|

||

|

5

|

Air pressure

|

0.7Mpa

|

||

|

6

|

Water consumption

|

15 Liters/min(15-20℃)

|

||

|

7

|

Air consumption

|

2000 Liters/min

|

||

|

8

|

Production Speed

|

600-1200 cycles/h

|

||

|

9

|

Voltage

|

AC380V±15V, 50HZ

|

||

|

10

|

Motor power

|

13kw

|

||

|

11

|

Power consumption

|

Max. 14KW/h

|

||

|

12

|

Heating plate power

|

38kw

|

||

|

13

|

Weight

|

6800kg

|

||

|

14

|

Dimension

|

6590*1760*2720 mm

|

||

Machine Made Samples

Product Detail

◆

Material feeding - forming & cutting - stacking

Step

❸

: ln-mould Forming & Cutting

Step

❹

: Stacking by Robot

◆

Highlights of the whole machine

The machine adopts the design of forming and stacking as a whole, which is easier to operate and maintain. Moreover, the machine body adopts thickened steel plate,which ensures the stability of large area forming and stacking.

◆

Feeding Part

The feeding part of the machine is integrated with the machine, which makes the

feeding process more stable and can bear larger material roll. The left and right of the

feeding frame are respectively controlled by a cylinder to ensure the stability of

feeding process.

◆

Pre-heating Part

Heating with electric heating rod can directly heat the sheet, improve the working

speed of the machine and enhance the transparency of the sheet. The surface of the

new preheating version is treated with Teflon coating, which is not easy to scratch the

material.

◆

Heating - Forming - Cutting Part

The machine could finish plastic sheet's heating, in-mould forming, cutting and

stacking in one process. The direct contact heating, forming and cutting method

makes the final products good shaping and accurate cut. Cutting is a way of sharing

blades, it makes material utilization rate high. Servo motor control make the machine

with low power consumption and easy maintenance.

◆

Stacking Part

After products finished, they are grasped and stacked by the manipulator automatically.

The guide rail for stacking is imported from Japan and controlled by servo motor to

ensure the stability of grabbing and stacking.

◆

Machine Driver

The machine adopts full servo motor control together with reducer. It makes the

machine running with small noise, lower consumption, more energy saving and easy

maintenance.

We have a complete production line and professional engineers, combined with

advanced technology

experience, to produce high-quality machines.

We have three CNC machines for manufacturing machine's mainly part, mold etc.

Mould production capacity of 5-10 sets per month.

Contact us

Hot Searches