- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

1600L

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ELE

-

Voltage:

-

380V,220V or 415V,440V

-

Dimension(L*W*H):

-

1100*500*1850mm

-

Power (kW):

-

75 kW

-

Motor:

-

Explosion-proof /no ex-prof

-

Shaft:

-

Single or double shaft

-

Lifting:

-

Hydraulic

-

Speed:

-

Variable control

-

Diameter of disc:

-

100-500mm

-

Capacity:

-

Depends on Customers' request

-

Certification:

-

CE /SGS

-

Power:

-

4~110kw

Quick Details

-

Barrel Volume (L):

-

2000

-

Max. Loading Volume (L):

-

2000 L

-

Range of Spindle Speed(r.p.m):

-

0 - 1500 r.p.m

-

Max. Loading Capacity:

-

1600L

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ELE

-

Voltage:

-

380V,220V or 415V,440V

-

Dimension(L*W*H):

-

1100*500*1850mm

-

Power (kW):

-

75 kW

-

Motor:

-

Explosion-proof /no ex-prof

-

Shaft:

-

Single or double shaft

-

Lifting:

-

Hydraulic

-

Speed:

-

Variable control

-

Diameter of disc:

-

100-500mm

-

Capacity:

-

Depends on Customers' request

-

Certification:

-

CE /SGS

-

Power:

-

4~110kw

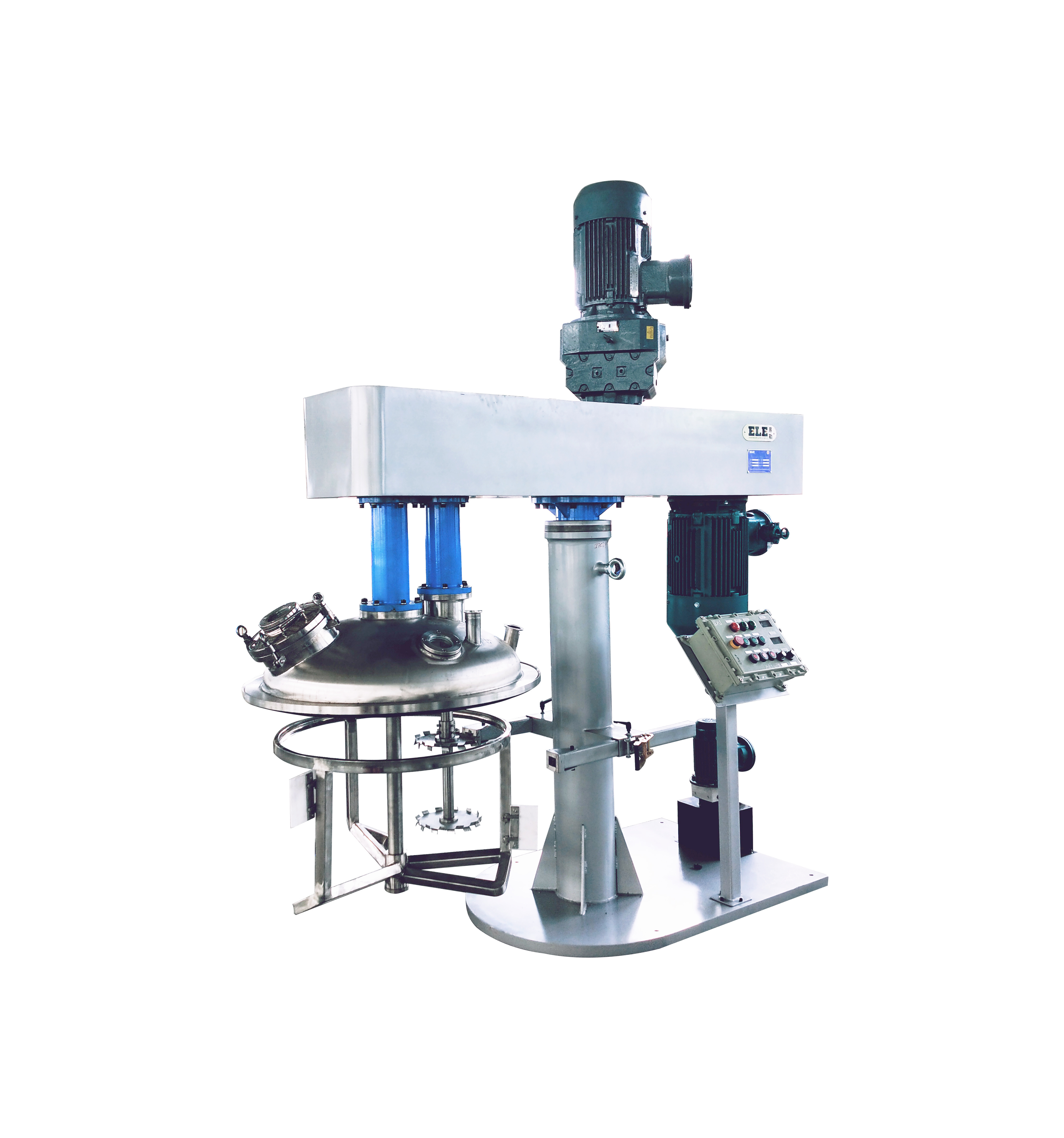

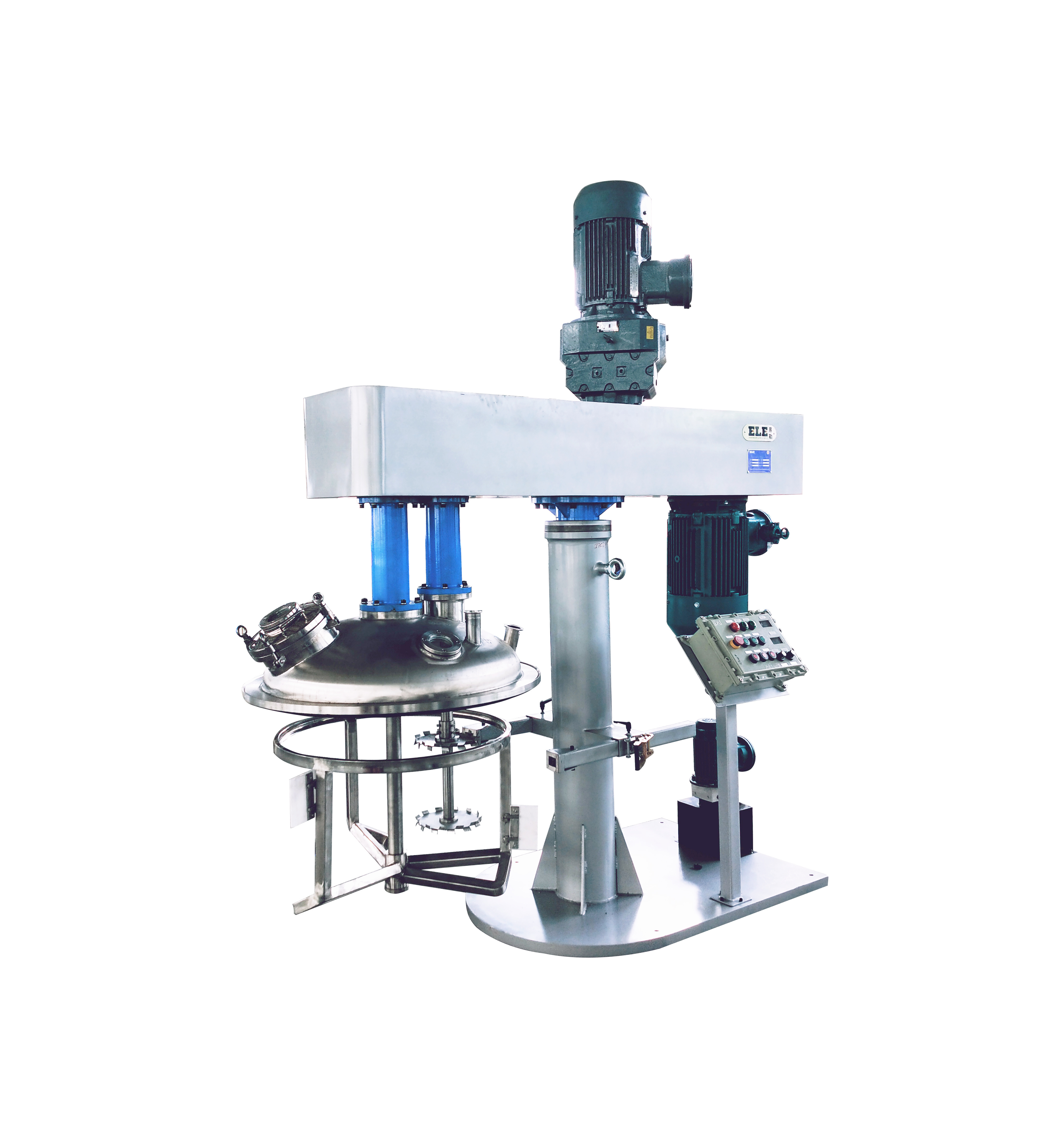

Industrial Butter mixer is suitable for high

-viscosity materials or materials easy to stick on the wall or special materials with thixotropic. Unique te

chnology, good mixing result, high efficiency.

Introduction

EBJ/II Series Mixer is suitable for mixing and despersing high viscosity materials.The mixing tank is movable, so it is convenient to change the material and advance the production efficiently.

This butterfly mixer integrates the butterfly agitator and high speed disperser in one,and it can do the process of dispersing and mixing in short time

Features of Industrial Butterfly Mixer

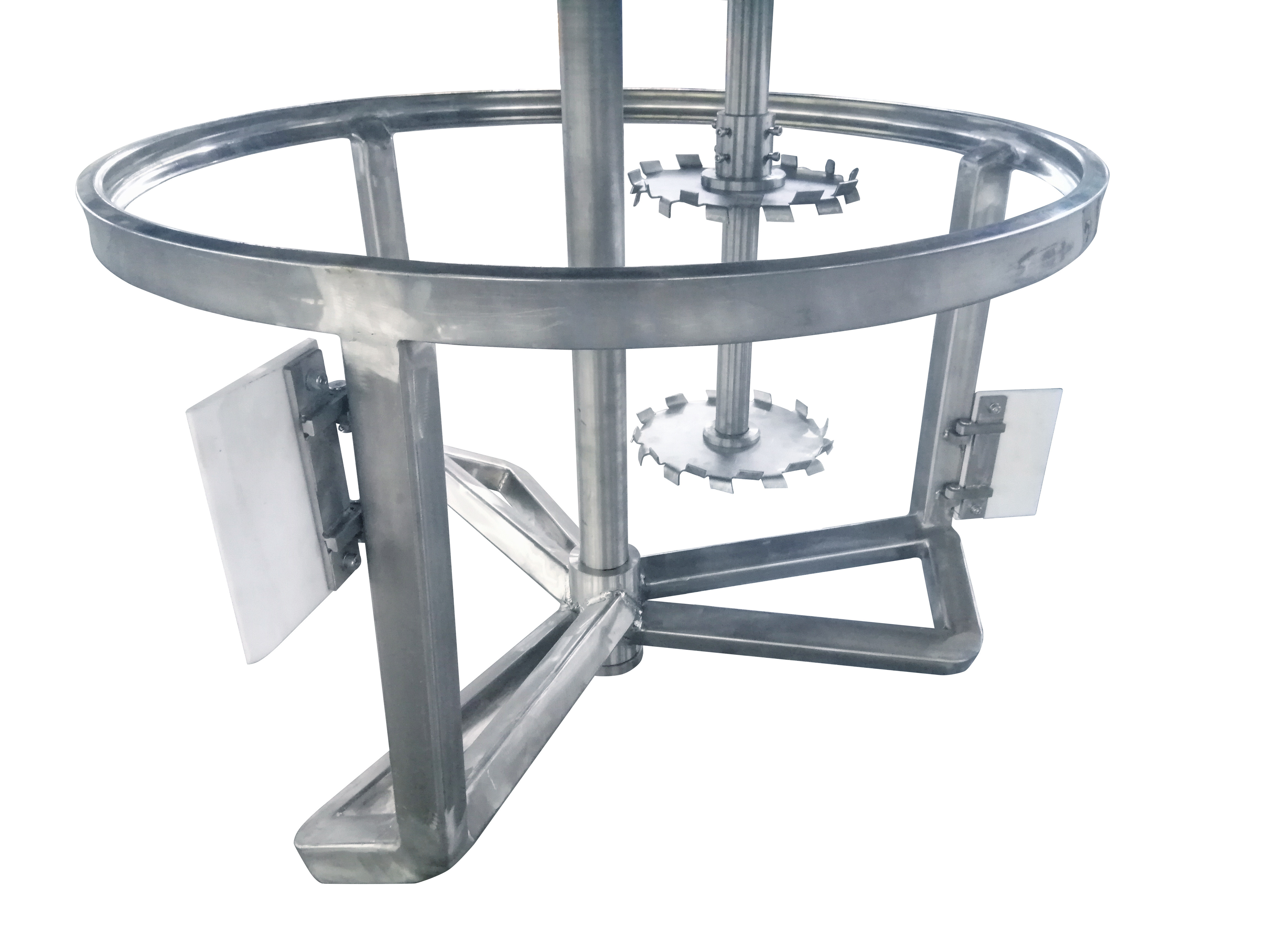

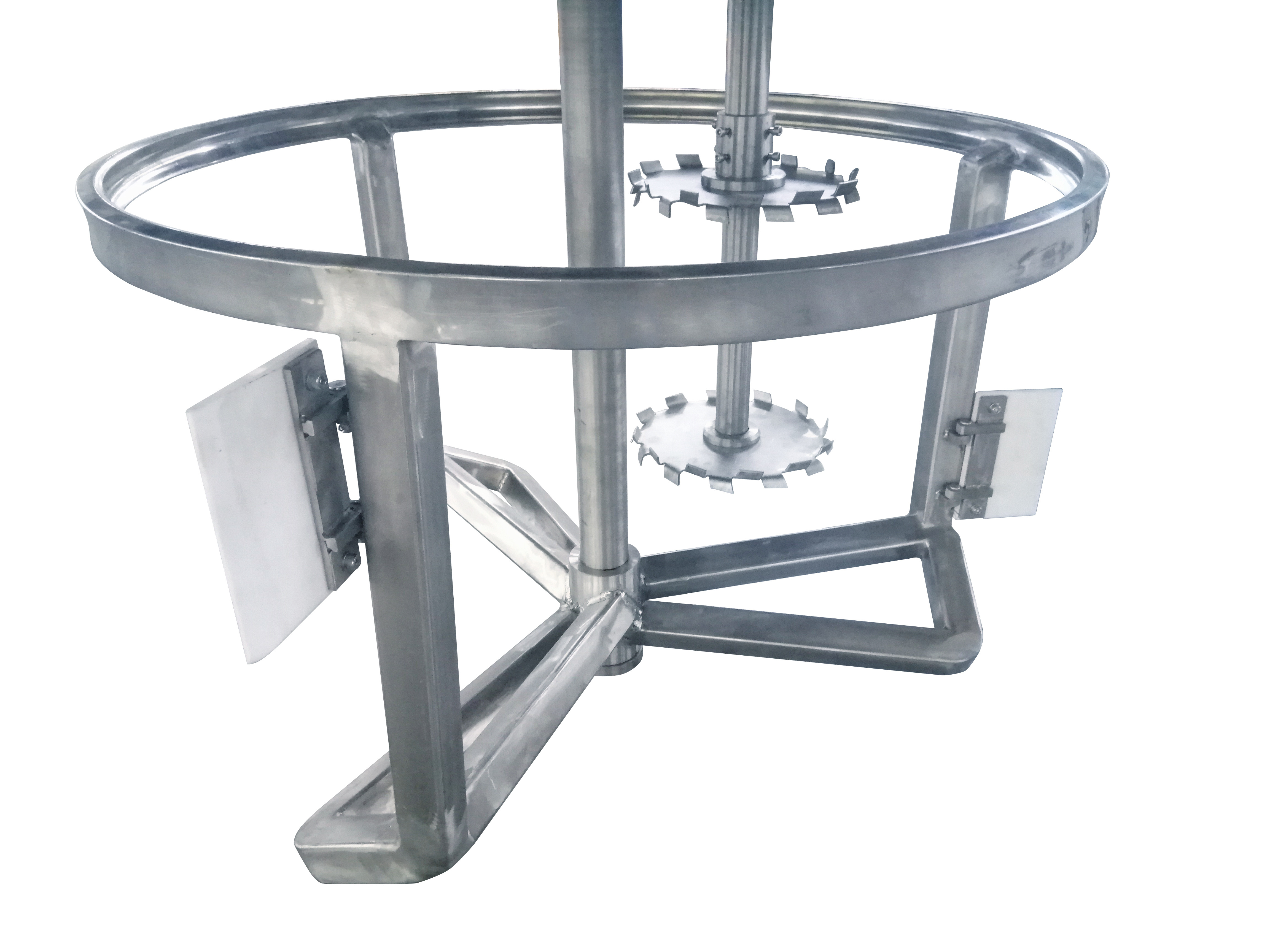

High speed disc with inverter to get various speed, gate agitator with scrapper with gear reducer

Middle paddle mixer with angle to make the material up side and down, at the same time the high speed disc rotate at a high speed to disperse and shear the product.

With clamp to fix the mixing tank during working.

ELE Services

Pre-Sale Service: ELE's skillful and experienced experts could provide you with professional technical consulting and designed proposal. We are owning modern Nano Laboratory and could help clients do test running before model selection and pirchasing, generate lab report and guide your actual production.

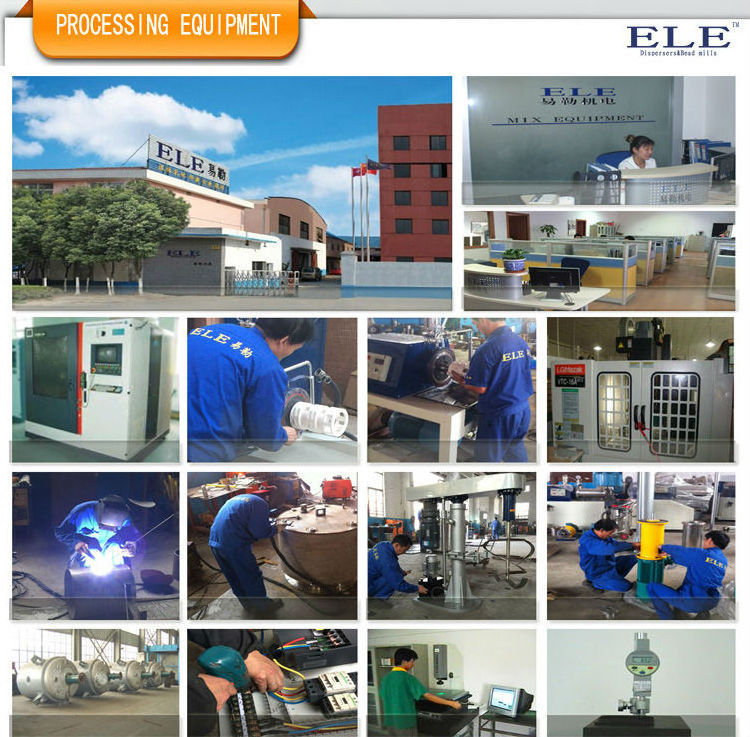

On-Sale Service:With upgraded grinding technology, ELE factory will manufacture good quality machinery and equipment to meet different production fields for customers.

After-sale Service: ELE engineers will be sandby for 24 hrs to provide you with prompt solution. We could send technicians to your factory to help you install the machine, train your workers to operate and help with the debugging.

All wearing parts of ELE machinery is available at any time you need. Our engineer will provide you with spare parts scheme before sending the equipment to help you know when it is needed to change the parts, thus avoiding any delay of yous productions.

Why ELE

Shanghai ELE Mechanical and Electrical Equipment Co., Ltd is professional manufacturer of wet processing chemical machinery. Owning 18 years experiences in dispersing and wet grinding field, ELE is your best choice for disperser, lab use sand/bead mill and inustrial sand/bead mill. With cooperation with university , experts and exprienced engineers, ELE has been concentrated in technique of wet grinding machine since 2000. Now ELE wet grinding mills are applied in more than 100 countries, serving for factory production of paint, ink, dye, magnetic material, paste, agriculture chemicals, adhesion, cosmetics, ceramic. With own modern Nano Laboratory and manufacturing factory, ELE could provide clients with the most suitable solution for complete wet gridning production mills. We are expecting cooperation with you!

More about ELE

lab high speed disperser homogenizer