- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 60HZ

-

Weight:

-

20 KG

-

Dimension(L*W*H):

-

Custimized

-

Product name:

-

Industrial Oxygen Generator

-

Color:

-

Custimized

-

Application:

-

Hospital Oxygen Generator

-

Technology:

-

Pressure Swing Adsorbtion (PSA)

-

Purity:

-

93+/-3%

-

Capacity:

-

3-50Nm3/h Psa Oxygen Generator

-

Type:

-

Make Oxygen

-

Function:

-

Oxygen Making

-

Advantage:

-

Low Power Consumption

-

Product:

-

Oxigeno Industrial Generador

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

AD

-

Production Rate:

-

100%

-

Voltage:

-

220V 60HZ

-

Weight:

-

20 KG

-

Dimension(L*W*H):

-

Custimized

-

Product name:

-

Industrial Oxygen Generator

-

Color:

-

Custimized

-

Application:

-

Hospital Oxygen Generator

-

Technology:

-

Pressure Swing Adsorbtion (PSA)

-

Purity:

-

93+/-3%

-

Capacity:

-

3-50Nm3/h Psa Oxygen Generator

-

Type:

-

Make Oxygen

-

Function:

-

Oxygen Making

-

Advantage:

-

Low Power Consumption

-

Product:

-

Oxigeno Industrial Generador

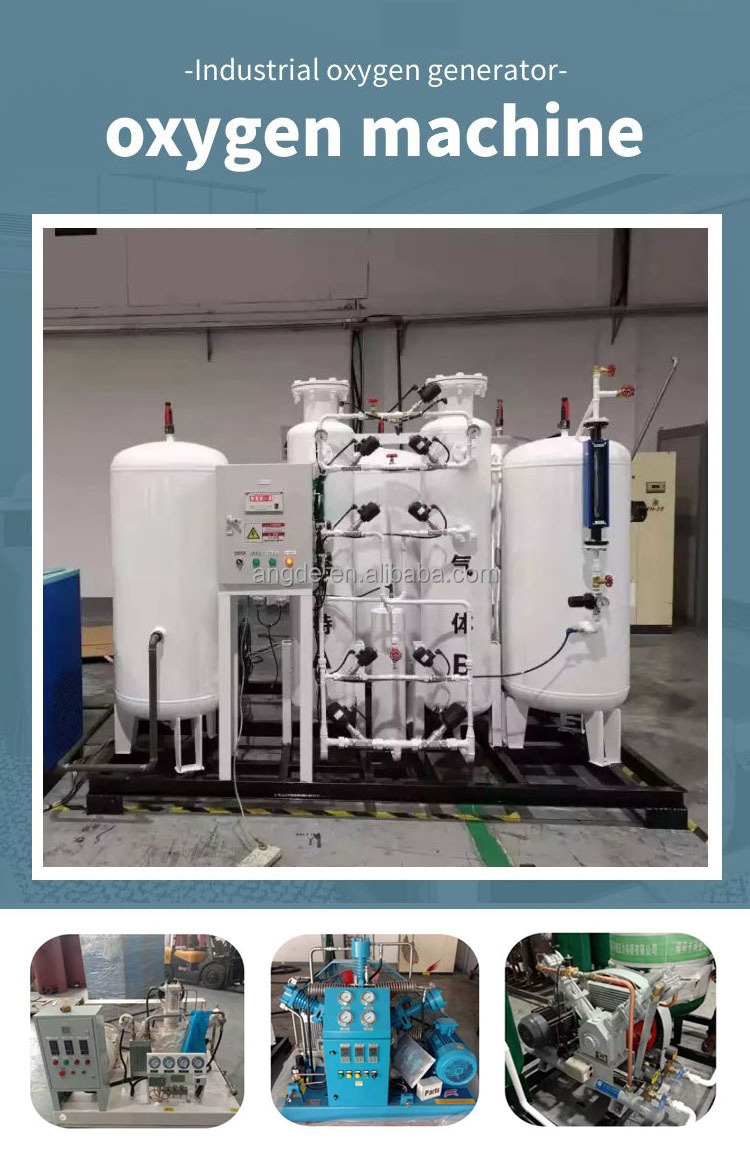

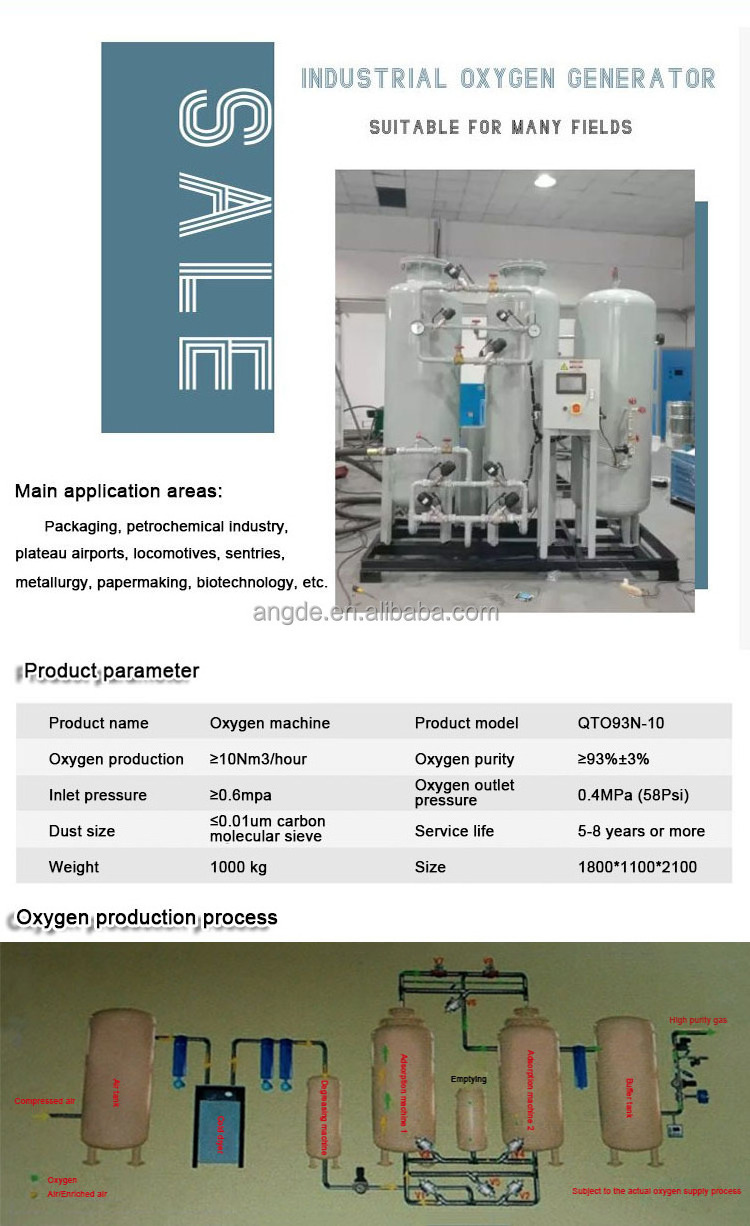

Product Parameters

I

ndustrial oxygen generators are favored by users with their obvious advantages, and are widely used in metallurgical combustion, chemical industry, environmental protection, building materials, light industry, medical treatment, aquaculture, biotechnology, sewage treatment and other fields.

The pressure swing adsorption industrial oxygen generator is an automatic equipment that uses zeolite molecular sieve as the adsorbent, and uses the principle of pressure adsorption and decompression desorption to adsorb and release nitrogen from the air, thereby separating oxygen. Zeolite molecular sieve is processed by a special pore type treatment process. The spherical particle adsorbent with micropores on the surface and inside is white. Its pore type characteristics enable it to realize the kinetic separation of 02 and N2. The separation effect of zeolite molecular sieve on 02 and N2 is based on the slight difference in the dynamic diameter of the two gases. N2 molecules have a faster diffusion rate in the micropores of zeolite molecular sieve, and O2 molecules have a slow diffusion rate. The diffusion of water and CO2 in compressed air is not much different from that of nitrogen. The final enrichment from the adsorption tower is oxygen molecules.

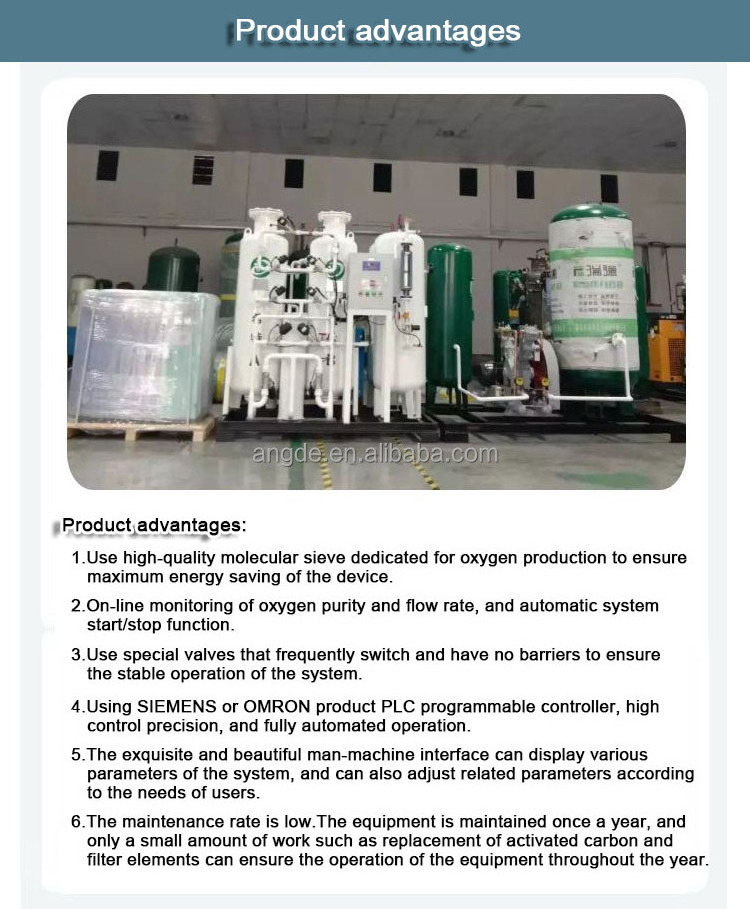

The valve switching of the entire system is automatically controlled by PLC, with a high degree of automation, and can be operated unattended. Convenient installation, compact equipment structure, overall skid-mounted, small floor space, no capital investment, and low investment. High-quality zeolite molecular sieve has large adsorption capacity and high compressive strength, and has unique molecular sieve protection measures, which prolongs the service life of molecular sieve. With air as the raw material, the energy consumption is only the electric energy consumed by the air compressor, which has the advantages of low operating cost, low energy consumption, and high efficiency. At the same time, it can be equipped with automatic oxygen purity alarm system, remote monitoring system and so on.

Packing & Delivery

1.Packed by standard import & export wooden cases or carton boxes.

2. Shipping:Courier service,Air transport,Sea Transport

2. Shipping:Courier service,Air transport,Sea Transport

Hot Searches