- Product Details

- {{item.text}}

Quick Details

-

Power:

-

18.5kw

-

Dimension(L*W*H):

-

11000mmx1960mmx1300mm

-

Weight:

-

7.2 kg

-

Forming speed:

-

0-18m/min

-

Forming steps:

-

16 steps + some auxiliary rollers

-

Thickness of material:

-

1.0-3.0mm

-

Tolerance of cutting length:

-

±1.5mm

-

Roll former:

-

1 set

-

Material of roller:

-

GCr15 with quenching treatment(HRC58-62)

-

Motor for transverse moving:

-

3KW(0.75x2+1.5KWx1)

-

Punching mould:

-

2 (holes can be adjusted)

-

Material of up/down mould:

-

Cr12MOV

-

Heat treatment of mould:

-

quenching HRC58-60

Quick Details

-

Production Capacity:

-

300-700m/h

-

Place of Origin:

-

China

-

Brand Name:

-

almaco

-

Power:

-

18.5kw

-

Dimension(L*W*H):

-

11000mmx1960mmx1300mm

-

Weight:

-

7.2 kg

-

Forming speed:

-

0-18m/min

-

Forming steps:

-

16 steps + some auxiliary rollers

-

Thickness of material:

-

1.0-3.0mm

-

Tolerance of cutting length:

-

±1.5mm

-

Roll former:

-

1 set

-

Material of roller:

-

GCr15 with quenching treatment(HRC58-62)

-

Motor for transverse moving:

-

3KW(0.75x2+1.5KWx1)

-

Punching mould:

-

2 (holes can be adjusted)

-

Material of up/down mould:

-

Cr12MOV

-

Heat treatment of mould:

-

quenching HRC58-60

Recommend Products

Products Description

Introduction

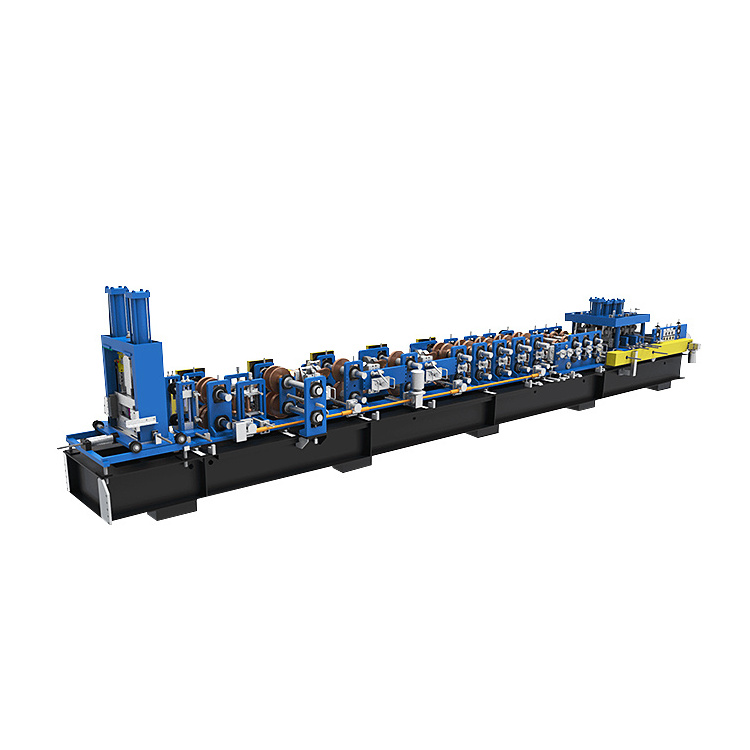

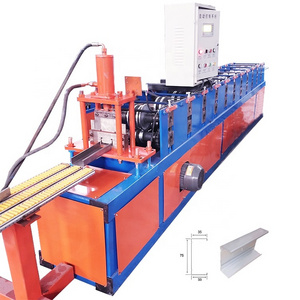

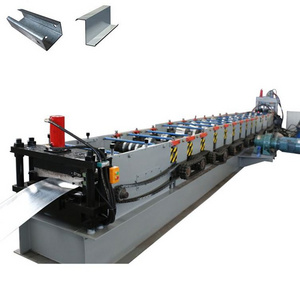

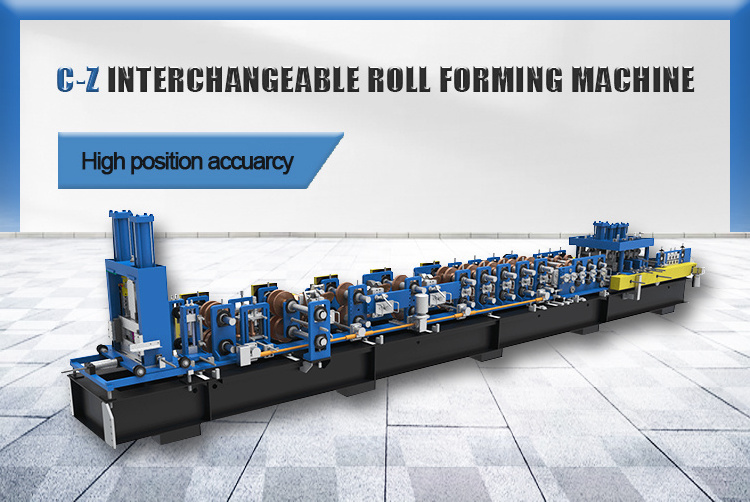

C-Z quick interchangeable machine adopts a special structure. The rollers for C & Z are changed very quickly without dismantle any parts. One machine can produce all specifications of C & Z purlins. This machine adopts steel coils as material and gets profiled steel after the process of coiling, cutting, punching, and roll forming. Whole machine adopts PLC controlling, AC frequency speed regulating to fulfill the automatic production, which is very suitable for the metal cold rolled processing industry.

Passive uncoiling → feeding with guide → leveling → roll forming→ hydraulic punching →hydraulic cutting→ output with table

Features:

1.Produce different purlin size without changing rollers or spacers.

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost

4.Infinite sizing(any size within machine range),help to save material

5.Optional Punch hole at any position of purlin web side and flange side

2.No need changing cutter for different size.

3.Easy operation, low maintenance cost

4.Infinite sizing(any size within machine range),help to save material

5.Optional Punch hole at any position of purlin web side and flange side

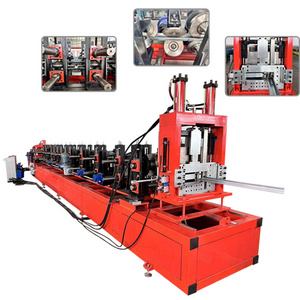

Roll former machine stand

Guide feeding

Hydraulic punching

Specification

|

Item

|

Parameters

|

|

Coil Thickness(mm)

|

1.5~3

|

|

Max Speed(m/min)

|

30

|

|

Roll standard station (pcs)

|

18

|

|

Main Motor(KW)

|

22kw (Hydraulic Motor )

|

|

Main Shaft(mm)

|

80mm

|

|

Shaft materials

|

40Cr

|

|

Roller Materials

|

GCr15

|

|

Cutting Way

|

Hydraulic Cutting (7.5KW)

|

|

Cutting Blade Materials

|

Cr12MoV

|

|

Hole Punching

|

3 sets

|

|

Control System

|

PLC control (Xinjie)

|

|

Size Change

|

PLC control / Press Button

|

|

C Z Interchange

|

PLC control / Reverse roll

|

Hot Searches