1)PET bottle manufacturing: preforms are sent into automatic blow molding machine via elevator and blow PET bottle, which is suitable for the requirement. Then bottles are sent into 3 in 1 filling system via air conveyor by bottle unscramble or directly.

2)Water

Preparation

: raw water is treated into requested water by water treatment and pump into filling system.

3)Washing water: the treated water is pumped into washing system of filling machine.

4)Air cleaning system for the filling system: after pre filtering by filter, air is supplied into filling machine in order to the air is up to 10000 class standard. The inner of the machine is up to 1000 class standard. At the sametine, there is buffer room, clothing room, fan room to keep inside cleaning.

5)Cap sterilizing and unscrambling: caps are sent into caps sterilizer, then sent into cap unscrambling system by cap elevator. After cap unscrambling system, caps are feed into capper.

6)Filling and capping: after filling machine, bottles are full of water and sent into capper to cap. And it becomes half-finished goods.

7)Second packaging: fulled bottles are storage in ware house after lamp checking, drying, inserting and shrinking label, and PE film shrinking machine.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HANYU

-

Year:

-

2023

-

Voltage:

-

380-220-110v/50-60hz

-

Dimension(L*W*H):

-

5.0*1.9*2'0m

-

Hollow part volume:

-

100-2000ml

-

Clamping Force (kN):

-

600

-

Power (kW):

-

80

-

Weight (KG):

-

6000 KG

-

Automatic:

-

yes

-

Name:

-

plastic bottle making machine

-

Type:

-

Full-auto

-

Product name:

-

Automatic Blowing Molding Machine

-

Machine type:

-

High Speed Plastic Bottle Making Machine

-

Capacity:

-

6000pcs/h

-

Use:

-

Making PET Bottle

-

Key words:

-

PET Stretch Bottle Blowing Molding Machine

-

Keywords:

-

Fully Automatic Bottle Blowing Machine

-

Blow Moulding Type:

-

Stretch Blow Moulding

Quick Details

-

Neck Diameter(mm):

-

30 mm

-

Max.Bottle Diameter(mm):

-

105 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HANYU

-

Year:

-

2023

-

Voltage:

-

380-220-110v/50-60hz

-

Dimension(L*W*H):

-

5.0*1.9*2'0m

-

Hollow part volume:

-

100-2000ml

-

Clamping Force (kN):

-

600

-

Power (kW):

-

80

-

Weight (KG):

-

6000 KG

-

Automatic:

-

yes

-

Name:

-

plastic bottle making machine

-

Type:

-

Full-auto

-

Product name:

-

Automatic Blowing Molding Machine

-

Machine type:

-

High Speed Plastic Bottle Making Machine

-

Capacity:

-

6000pcs/h

-

Use:

-

Making PET Bottle

-

Key words:

-

PET Stretch Bottle Blowing Molding Machine

-

Keywords:

-

Fully Automatic Bottle Blowing Machine

-

Blow Moulding Type:

-

Stretch Blow Moulding

Product Description

|

6 cavity blow molding machine

|

|

|

|

|||

|

CONTAINER

|

Max.Container Volume

|

L

|

0.75

|

|||

|

|

Cavity

|

|

6

|

|||

|

|

Theoretical Output

|

BPH

|

8000-9000

|

|||

|

ELECTRICAL

|

Heating Power

|

KW

|

35

|

|||

|

|

|

|

|

|||

|

|

Installed Power

|

KW

|

48

|

|||

|

|

Total Power

|

KW

|

60

|

|||

|

COMPRESSEDAIR

|

Operating Power

|

MPA

|

0.87

|

|||

|

|

Air Consuming

|

L/MIN

|

1400

|

|||

|

|

Blowing Pressure

|

MPA

|

3.5

|

|||

|

|

Air Consuming

|

L/MIN

|

4500-5500(**)

|

|||

|

CHILLED WATER

|

Pressure

|

MPA

|

0.3-0.5

|

|||

|

|

Temperature

|

C

|

10-12

|

|||

|

|

Flow Rate

|

T/H

|

4.5

|

|||

|

MACHINE

|

Size(L*W*H)

|

M

|

4.5*2.0*2.03

|

|||

|

|

Weight

|

KG

|

6500

|

|||

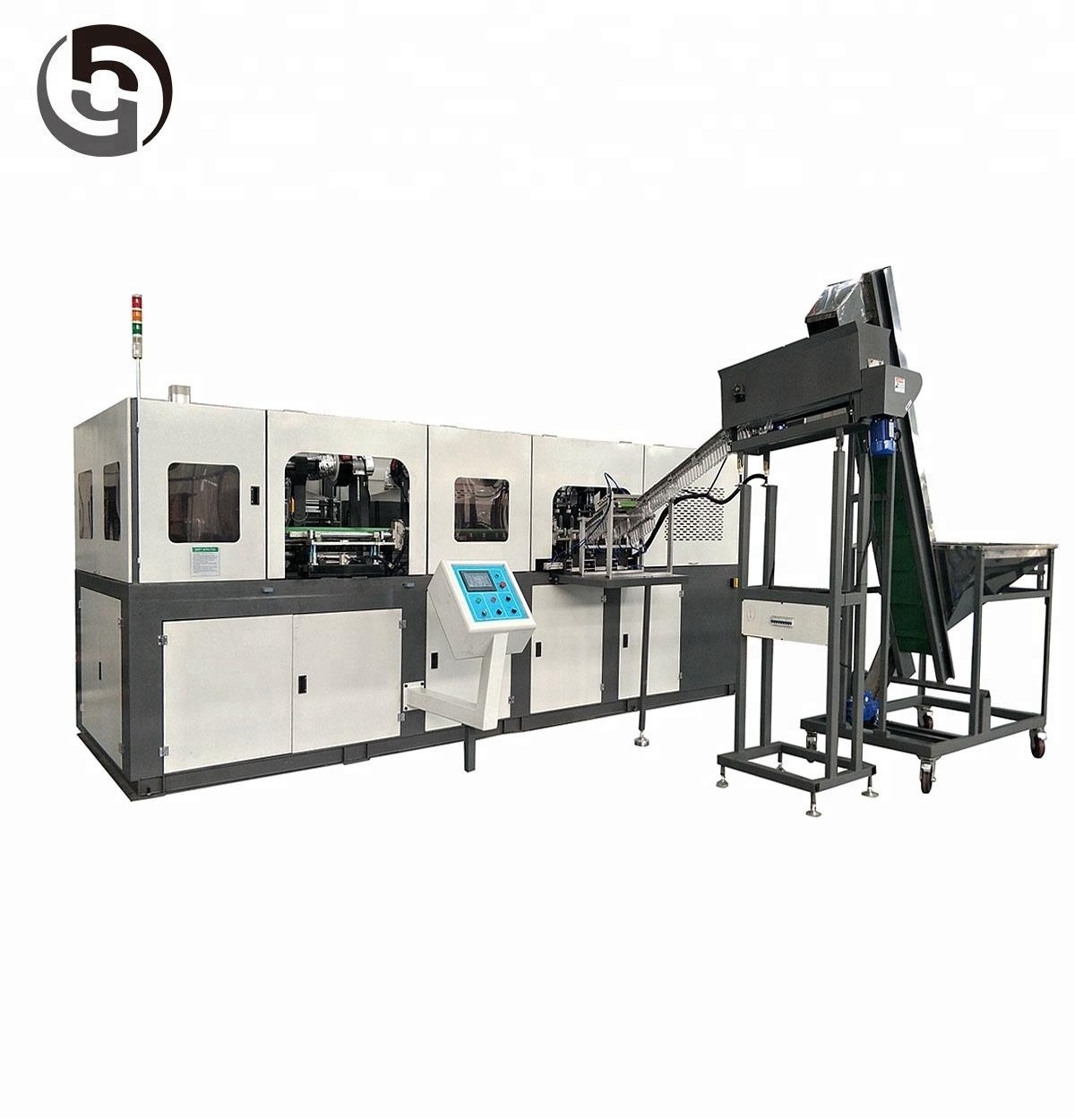

HY-A6 is the fastest liner blow molding machine in mainland of China by now. HY- A6 reaches around 9000BPH for 350ML bottle. Its baking tunnel is separated from the blow station so that time for mold opening is shortened with a result of speedy blowing and high output, damage to machine is lessened so as to keep reliable performance and prolong service life, as well as machine runs more smoothly and steadily.

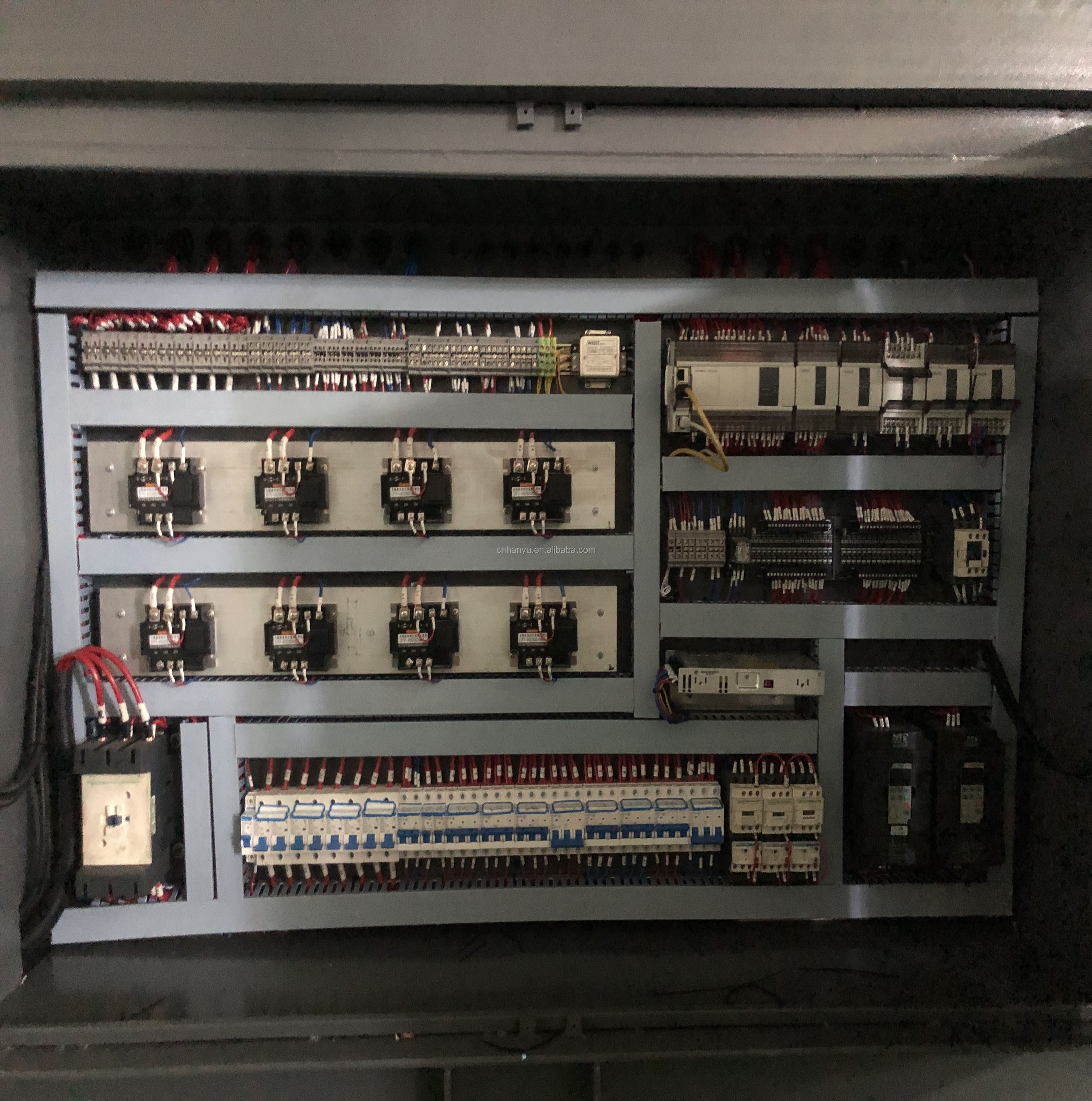

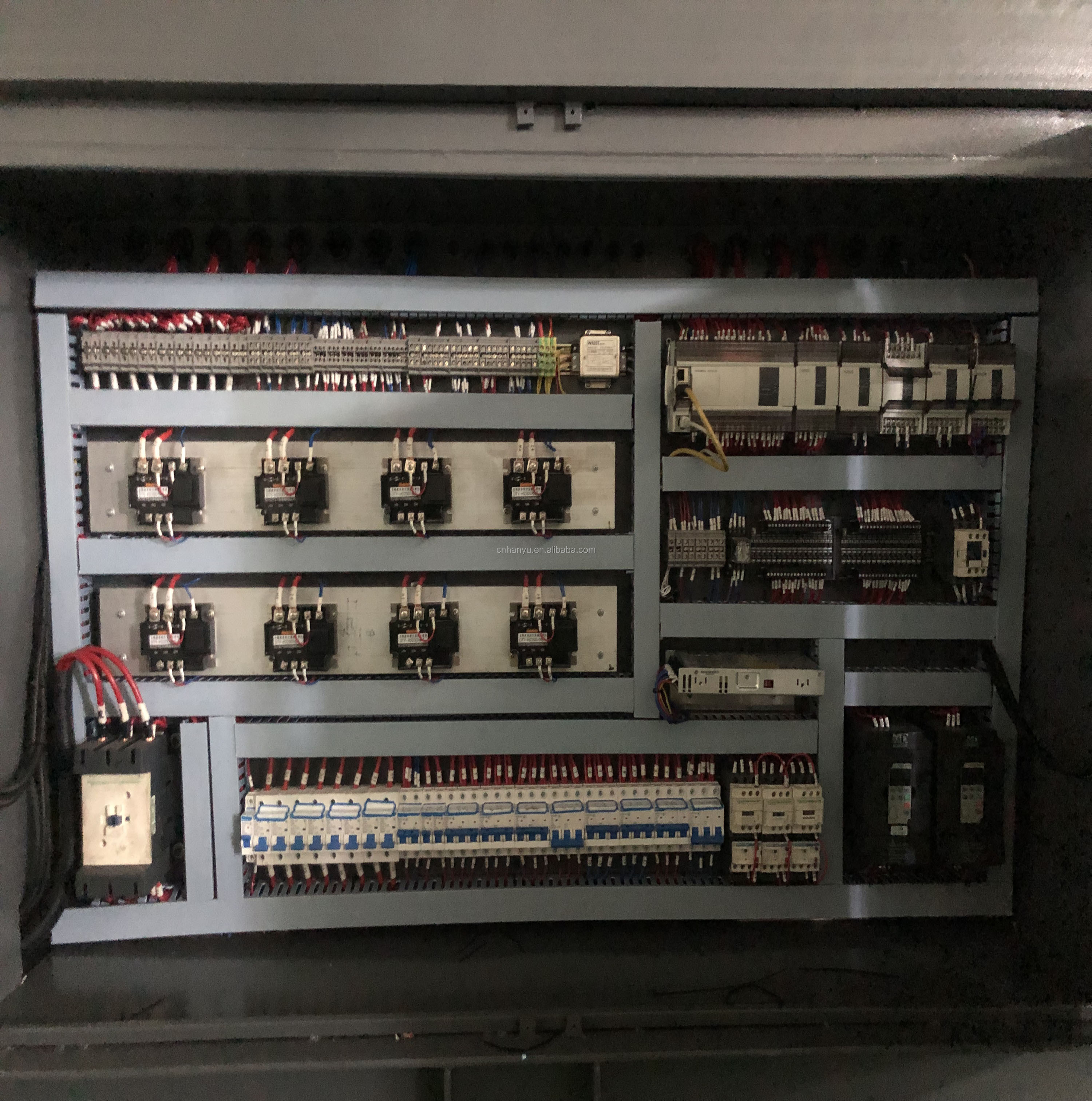

HY-A6 is controlled by PLC. The whole process from preform feeding to bottle discharging is completed automatically with advantages of labor saving and no pollution. HY-A6 consists of three main parts: preform loading system, Heater channel & blow station.

MACHINE FEATURES:

1. Machine use of advanced PLC control system , stable in performance, automatic preform feeding .

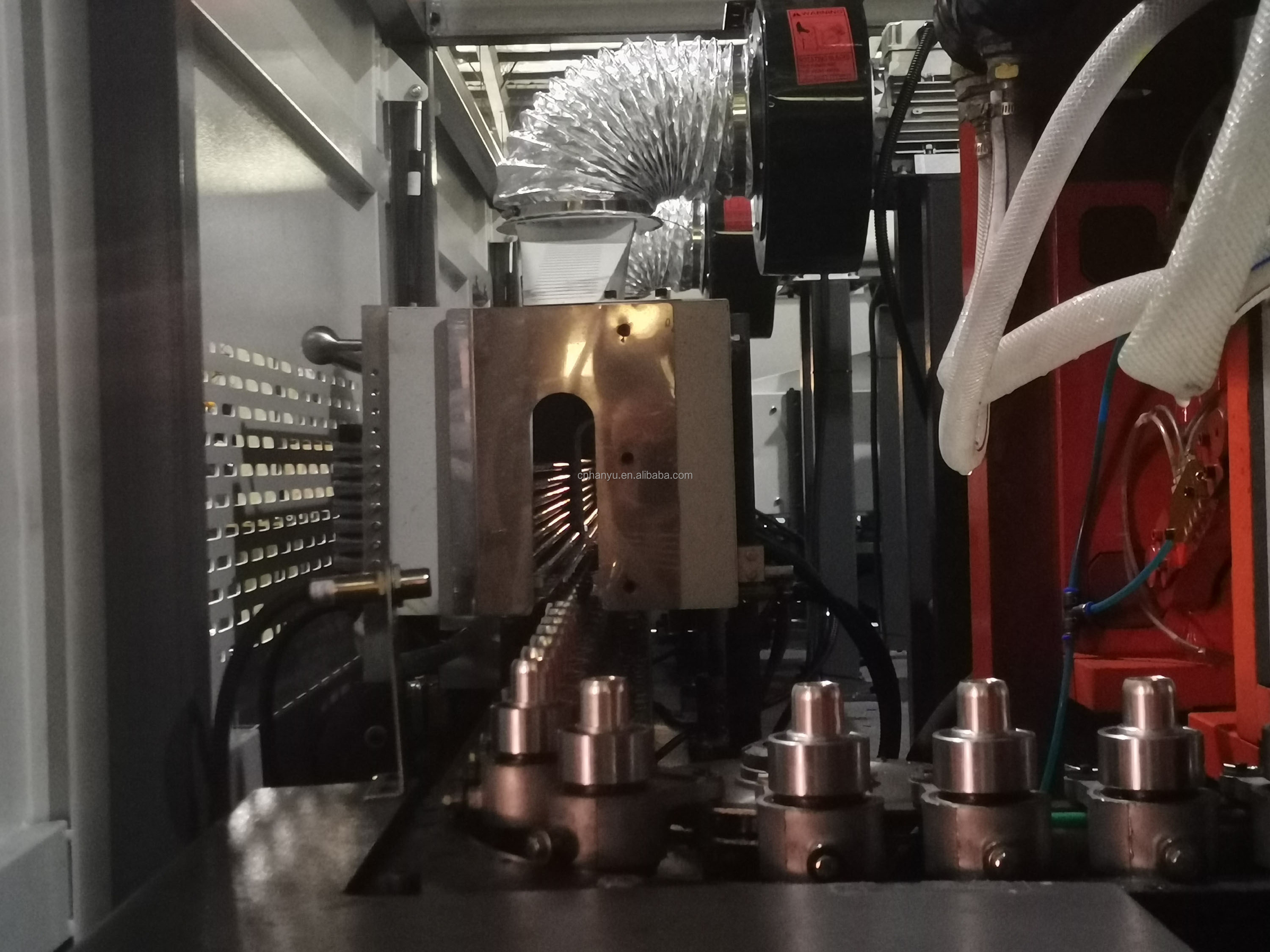

2. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater

3. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

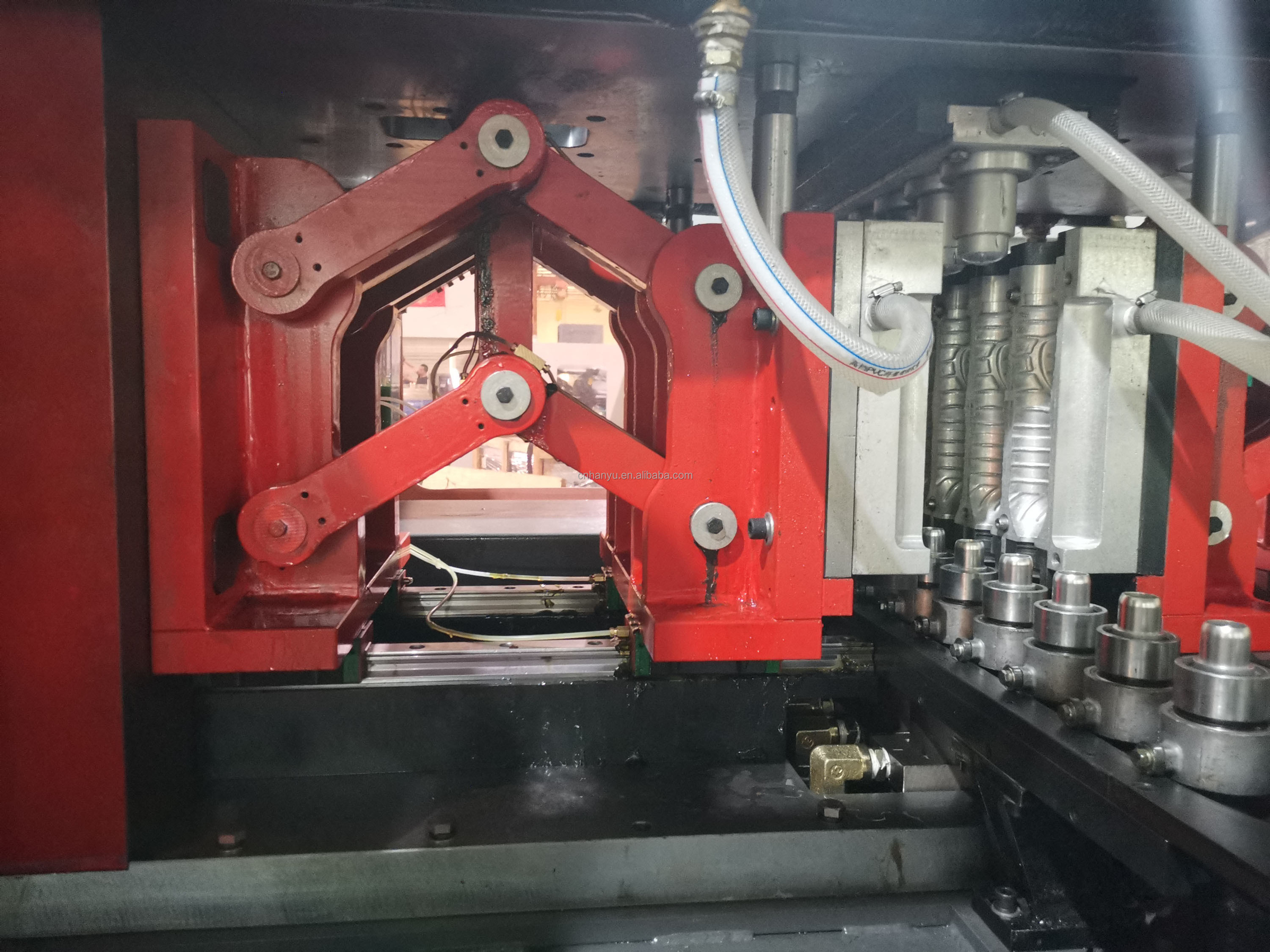

4. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

5. No contamination and low noise with the air cylinder to drive the action instead of the oil

pump.

6. Air route design is divide into two parts ,

7. Ideal effect of the chilling with the chilling system

8. Low rejection rate: less than 0.3percent

Detailed Images

The servo bottle blowing machine achieves precise control of parameters such as pressure, speed, and measurement accuracy during

the blowing process by controlling the operation of the servo motor, thereby greatly improving production efficiency and product

quality.

the blowing process by controlling the operation of the servo motor, thereby greatly improving production efficiency and product

quality.

Adopting infrared heating mode. Its strong thermal radiation and penetration ability enable the machine to reach the required

temperature during high-speed operation. Infrared light tubes are distributed in three heating zones, with corresponding

independent voltage adjustment modules and computer control systems, which can provide ideal heating effects for different types of preform. The horizontal position of each infrared light tube can be adjusted to increase the flexibility of the machine.

temperature during high-speed operation. Infrared light tubes are distributed in three heating zones, with corresponding

independent voltage adjustment modules and computer control systems, which can provide ideal heating effects for different types of preform. The horizontal position of each infrared light tube can be adjusted to increase the flexibility of the machine.

Using Servo System, high-tech human-computer interaction control panel, lightweight touch screen (optional), accurate control,

simple parameter setting, clear numerical display, ideal memory storage capacity

simple parameter setting, clear numerical display, ideal memory storage capacity

Provide whole drawing for the perform mould and bottle mould. Free charge for word design on the mould

All moulds are designed by CAD/CAM.

production line

FAQ

Q1: Where is your factory located? How can I visit there?

Yes

warmly welcome to visit us ,we are in

Taizhou City, Zhejiang Province, China.

Q2: How long is the warranty

?

A2: All of products have one years warranty.

Q3: How can I install my machine when it arrives?

A3:

We will provide detailed installation videos for semi-automatic machine and provide 24-hour online support.

and if you need we will send our engineer to your side as soon as you get all your machines to testing and teaching your technicians how to run the machines.

Q4: How long is the delivery time?

Q4: How long is the delivery time?

A4: Under normal conditions, products are delivered within 45 working days for fully-auto machine,15days for semi-automatic machine

Q5: Where is the Shipping departure port?

Q5: Where is the Shipping departure port?

A5: Ningbo or shanghai port.

Q6: What’s the payment

Q6: What’s the payment

A6: T/T, L/C,Western Union, paypal.

Q7. What products does your company offer by yourself?

Q7. What products does your company offer by yourself?

A7: We are specialized in PET Blow Molding Machine, PET Blow Mold, Injection Machine, PET Preform Mold,Cap mold.

Q8: How about the quality of machine?

Q8: How about the quality of machine?

A8:

We have been producing bottle blowing machines since 1996 with extensive experience and

undergo repeated testing and inspection before shipment

Packing & Delivery

|

Packaging

|

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

|

Packaging

|

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Our Factory

Zhejiang Hanyu Automation Technology Co., Ltd

Zhejiang Hanyu Automation Technology Co., Ltd is a professional manufacturer of blow molding machines, Our team

have been involved in blow molding machine and mould industry since 1996

Machine manufacturing. integrating development and production together. Our main products include P E T full- automatic blow molding machine, semi-automatic blow molding machine, B O P P blow molding machine, hot-filling bottle blow molding machine, 5 gallon blow molding machine, preform mold, cap mold, bottle mold, plastic mold, injection machine and other related products. Hanyu Machinery has perfect manufacturing equipment and manufacturing system, with a high-quality, professional , persistent team.we can provide all technology to the customers from design to successful install.

Why Choose Us

Hot Searches