- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

matech

-

Diameter:

-

based on customer's needs

-

Car Model:

-

based on customer's needs

-

Item:

-

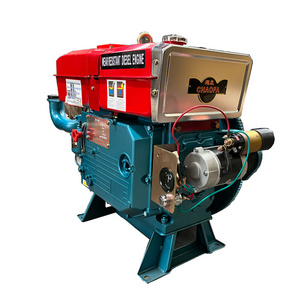

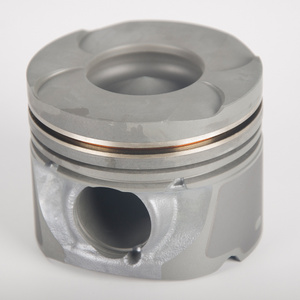

High Performance Marine Machinery Small Piston Engine Parts

-

Material:

-

Casting stainless steel 304, 316, 316L etc. As customers request.

-

Manufacturing Process:

-

Investment casting, option Lost wax casting

-

Casting Tolerance:

-

CT4-8 for stainless steel casting

-

Machining Process:

-

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.

-

Machining Tolearnce:

-

Up to IT7, Ra 0.8~3.2 , according to customer requirement

-

Surface Treatment:

-

Surface Passivatin, Polish. As customer request

-

Package of lost wax casting:

-

Multi-layer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

45 days

-

Our Service:

-

custom metal parts based on drawing

Quick Details

-

OE NO.:

-

oem customized

-

Size:

-

based on customer's needs

-

Warranty:

-

based on customer's needs

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

matech

-

Diameter:

-

based on customer's needs

-

Car Model:

-

based on customer's needs

-

Item:

-

High Performance Marine Machinery Small Piston Engine Parts

-

Material:

-

Casting stainless steel 304, 316, 316L etc. As customers request.

-

Manufacturing Process:

-

Investment casting, option Lost wax casting

-

Casting Tolerance:

-

CT4-8 for stainless steel casting

-

Machining Process:

-

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.

-

Machining Tolearnce:

-

Up to IT7, Ra 0.8~3.2 , according to customer requirement

-

Surface Treatment:

-

Surface Passivatin, Polish. As customer request

-

Package of lost wax casting:

-

Multi-layer wooden box/pallet, with big plastic bag inside

-

Lead Time:

-

45 days

-

Our Service:

-

custom metal parts based on drawing

|

Application

|

|

|

|

|

|

|||||

|

• Agricultural equipment

|

• Armament

|

• Automobile industry

|

• Computing equipment

|

• Medical / dental instruments

|

• Measuring instruments

|

|||||

|

•Miscellaneous equipment

|

•Pharmaceutical industry

|

• Orthopedic implants

|

• Safety equipment

|

• Petrochemical industry

|

• Industrial valves

|

|||||

|

•Fixing and movable equipment

|

• Sanitary fittings

|

• General machinery

|

• Pumps and general connections

|

• Food and beverage processing

|

• Instrumentation equipment

|

|||||

|

High Performance Marine Machinery Small Piston Engine Parts

|

|

|

|

Main Blank Process of casting stainless steel parts

|

Investment casting (wax mold made by middle temperature wax) ;

Lost Wax Casting (wax mold made by low temperature wax); |

|

|

Blanks Casting Tolerance

|

CT7-8 for Lost wax Casting Process CT4-6 for Investment casting Process

|

|

|

Applicable Material for casting stainless steel parts

|

Stainless Steel: G-X7CrNiNb1189, SUS 304, 304L, 316, 316L etc.

Or according to customer's requirement. |

|

|

Casting Blank Size /Dimension

|

2 mm-600mm / 0.08inch-24inch according to customer requirement.

|

|

|

Applicable Machining Process

|

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/

Broaching/Reaming /Grinding/Honing and etc. |

|

|

Machining Tolerance

|

From 0.005mm-0.01mm-0.1mm

|

|

|

Machined Surface Quality

|

Ra 0.8-Ra3.2 according to customer requirement

|

|

|

Applicable Heat Treatment

|

Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching etc.

|

|

|

Applicable Finish Surface Treatment

|

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate,Dacromat coating, Finish Painting, etc.

|

|

|

MOQ for mass production

|

For lost wax casting steel factory: 100pcs For Machining: 50pcs

|

|

|

Lead Time

|

45 days for high performance small engine parts

|

|

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve andPump system etc.

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies. These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Our customers have become our friends, also what we call family members. welcome to join us!!!

Our Team are a big happy family, we not only supplying products to our customers , but also trying to build more values to our customers' business by introducing suitable solution or technology to our customers with compromising parts' function, technologies' advantage, realization feasibility, cost control and quality reliability.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package. Or customized as per customer's requirements.

2. How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost, and the charge will be deducted from the payment for formal order.

3. Can you make stainless steel casting according to our drawing?

Yes, we can make daccording to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

4. Can you make stainless steel casting based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5. What’s your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of Stainless steel casting parts