- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KUNTENG

-

Voltage:

-

380V, Customized Accept

-

Dimension(L*W*H):

-

1950*2950*1700MM

-

Weight:

-

3000 KG, 1000kg

-

Applicable raw materials:

-

coal powder or charcoal powder

-

Keywords:

-

Coal Fine Ball Press Machine

-

Power:

-

5.5 kw

-

Capacity:

-

2000kg/h

-

Briquette shape:

-

can be cutomized

-

Features:

-

Easy Operation

-

MOQ:

-

1 Set

-

Briquette size:

-

can be customized

Quick Details

-

Application:

-

charcoal coal industry

-

Production Capacity:

-

10 tons per day

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KUNTENG

-

Voltage:

-

380V, Customized Accept

-

Dimension(L*W*H):

-

1950*2950*1700MM

-

Weight:

-

3000 KG, 1000kg

-

Applicable raw materials:

-

coal powder or charcoal powder

-

Keywords:

-

Coal Fine Ball Press Machine

-

Power:

-

5.5 kw

-

Capacity:

-

2000kg/h

-

Briquette shape:

-

can be cutomized

-

Features:

-

Easy Operation

-

MOQ:

-

1 Set

-

Briquette size:

-

can be customized

Product Description

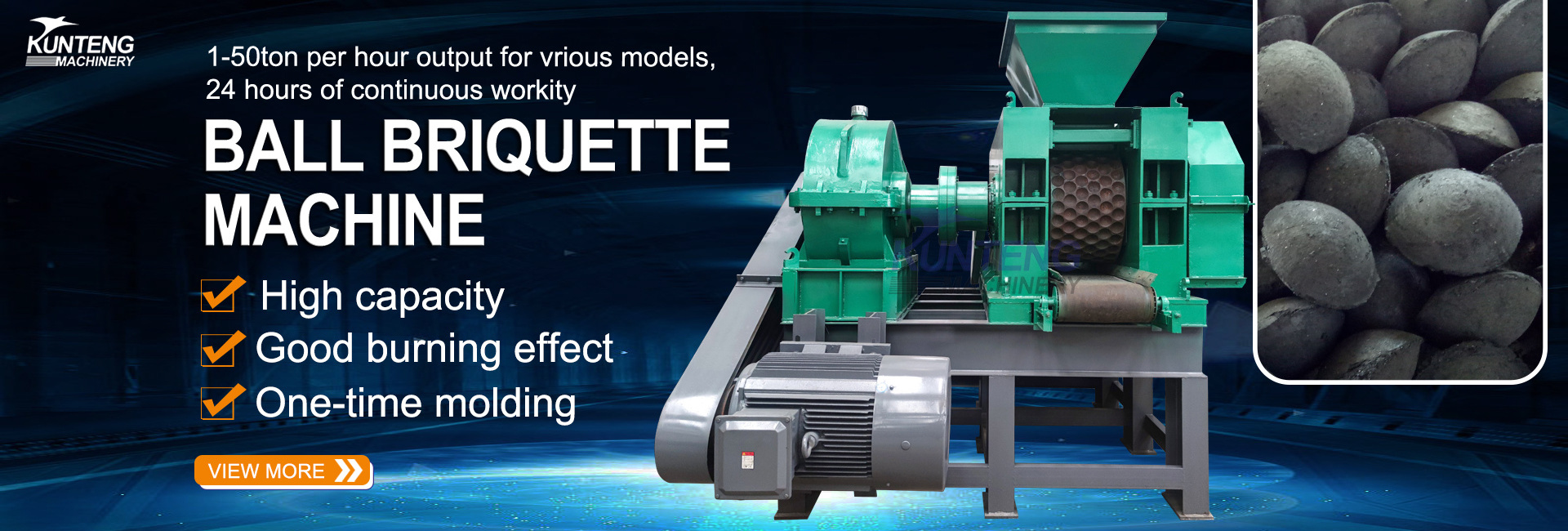

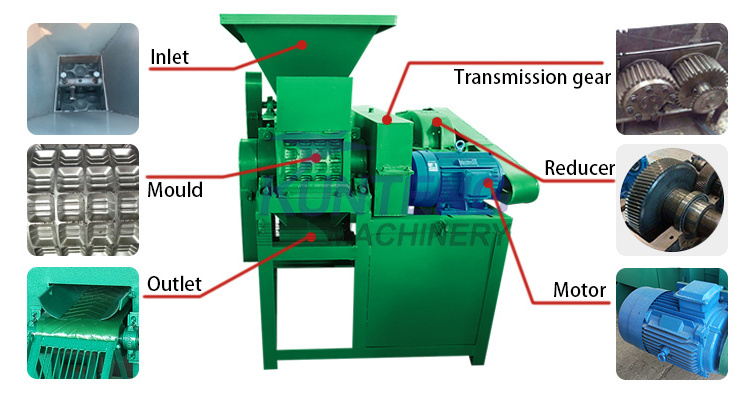

Ball press machine

is used for making coal fines, coke fines, charcoal powder, carbon black, carbon, salt, chemical salt, iron ore fines, silicon carbide, mineral powder, metal dust, cast iron dust, mill scale, manganese ore fines, fluorite powder, gypsum powder, ferrosilicon powder, and phosphor gypsum powder, nickel alloy, blast furnace ash, converter dust, coal gangue, Kaolin clay, MGO, NPK, graphite, oil shale, potash fertilizer, urea fertilizer, sea sand powder etc.

Into briquettes. These briquettes ball can be designed of oval shape, egg shape, pillow shape etc.

This ball press machine is widely used in coal industry, metallurgy industry, chemical industry etc.

Mold and Materials

Ball press machine

can press ore powder,metal powder,coal powder, coke powder and other materials into ball shape.

The charcoal or coal briquettes

can be different shapes by changing with special molds, such as oval,pillow, round,egg,ball,column and square.

We can also customize the shape for our customers.

Final

Briquetting Machine

have features of high density,high strength,high hardness,high performance,and the main rollers adopt hard wear resistance materials,which improve rolle's service life greatly.

|

Model

|

Roller

Diameter(mm)

|

Capacity(t/h)

|

Power(KW)

|

Reducer

|

|

KT-290

|

290

|

2T/H

|

5.5-7.5

|

350

|

|

KT-360

|

360

|

3T/H

|

7.5-11

|

350

|

|

KT-450

|

450

|

5T/H

|

18.5-22

|

400

|

|

KT-550

|

550

|

10T/H

|

22-30

|

500

|

|

KT-650

|

650

|

15T/H

|

30-45

|

650

|

|

KT-850

|

850

|

20-25T/H

|

90

|

850

|

|

KT-1000

|

1000

|

30T/H

|

110

|

1000

|

Briquetting Machine

is after crushing mixing materials will be direct production, mainly to suppress various, scrap iron, iron ore powder, aluminum powder, refractory material, etc. It is

widely used in refractory material, power plants, metallurgical, chemical, energy, transportation,

heating and other industries.

Our company has other models of equipment, please contact us if needed

Process Flow

Matched products of charcoal ball press machine

For some raw materials that cannot be directly formed through a ball pressing machine, such as rice husks, coconut husks, etc., they need to be used in conjunction with a carbonization furnace

Hoisting carbonization furnace

Horizontal carbonization furnace

Lifting Carbonization Furnace And Horizontal Carbonization Furnace

The charcoal ball press machine

needs to be equipped with a carbonization furnace, which can be either a lifting carbonization furnace or a horizontal carbonization furnace.

The carbonization furnace is specially designed for the characteristics of long strips of biomass such as waste wood, branches, sawdust, rice husks, and peanut shells.

Volatile hydrogen substances and tar,etc recombustion technology to meet the heat demand of the carbonization furnace itself; make full use of the flue gas generated during the carbonization process, greatly improving the carbonization rate, and the operation is simple, safe and environmentally friendly, high production efficiency, and can save a lot It is an ideal equipment for carbonization of biomass materials.

Through the combination of multiple equipment, the carbonization flue gas is used in series, which can reduce the fuel consumption in the carbonization production process and improve economic and enterprise benefits.

We can provide purchase links for our company's supporting products and provide corresponding technical installation guidance and after-sales service

Please send us an email

CUSTOMER VISIT

Hot Searches