◆

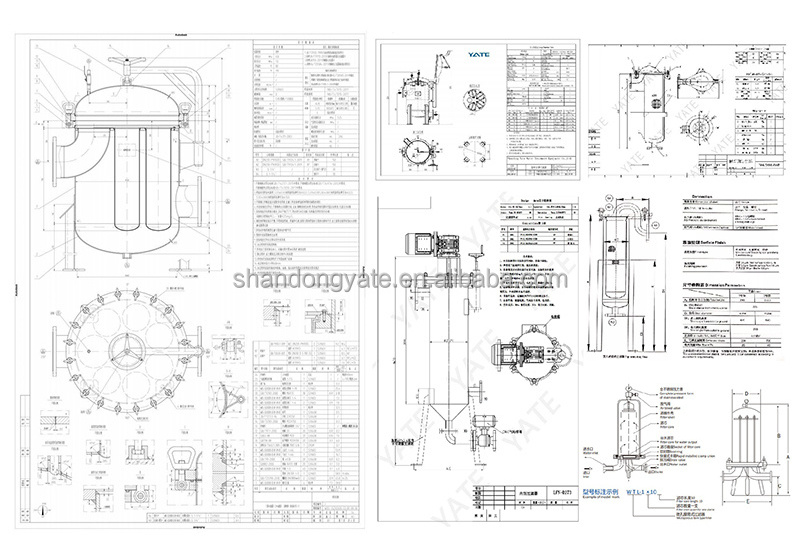

1.The first filter is bag filter, which can be customized for 1-24 bags, with a filtering accuracy of 0.2-500 microns, and intercepts large particle impurities.

◆

2.The second filter is cartridge filter, can be customized 3-100 cores, filtration accuracy 1-300 micron, fine filtration.

◆

3.The third stage is the folding filter element filter, high precision filtration, reduce turbidity, filtration accuracy 0.1-300 micron.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

stainless steel filter housing

-

Application:

-

industrial chemical filtration

-

Type:

-

Single bag / multiple bags

-

Material:

-

Stainless Steel 304

-

Usage:

-

Liquild Filter

-

Size:

-

Customized Size

-

Name:

-

High pressure bag filter

-

Working Pressure:

-

0.6Mpa

-

Filter Material:

-

PP/PE

-

Min. Filtration Precision:

-

0.5 μm

Quick Details

-

Weight (KG):

-

150

-

Place of Origin:

-

China

-

Brand Name:

-

YATE

-

Product name:

-

stainless steel filter housing

-

Application:

-

industrial chemical filtration

-

Type:

-

Single bag / multiple bags

-

Material:

-

Stainless Steel 304

-

Usage:

-

Liquild Filter

-

Size:

-

Customized Size

-

Name:

-

High pressure bag filter

-

Working Pressure:

-

0.6Mpa

-

Filter Material:

-

PP/PE

-

Min. Filtration Precision:

-

0.5 μm

High-quality Surface Finish Liquid Oil Wine Beer Paint Waster Water Treatment Filter Housing Equipment

Products Description

Advantages of bag filter and cartridge filter :

◆ High capacity, small size

◆ Easy to replace the filter bag, labor saving

◆ After cleaning the filter bag can be used repeatedly to save cost

◆ Filter precision reached 0.5-500 μm

◆ Lower leakage risk ensures high quality

◆ High working pressure, low pressure loss, low operation cost and energy saving

◆ Wide application, flexible use, various installation model for choice.

◆ Easy to replace the filter bag, labor saving

◆ After cleaning the filter bag can be used repeatedly to save cost

◆ Filter precision reached 0.5-500 μm

◆ Lower leakage risk ensures high quality

◆ High working pressure, low pressure loss, low operation cost and energy saving

◆ Wide application, flexible use, various installation model for choice.

|

Model

|

Filter bag#

|

Filter bag Qty

|

Firltration area(m²)

|

Connection

|

Max. Flow (m³/h)

|

Working pressure(MPa)

|

|

YT-1D

|

1#

|

1

|

0.25

|

DN50

|

20

|

0.5-1.6

|

|

YT-2D

|

2#

|

1

|

0.5

|

DN50

|

40

|

0.5-1.6

|

Details Images

Three Stage Filter Unit

Two Stage Filter Unit

◆1.The first filter is bag filter, which can be customized for 1-24 bags, with a filtering accuracy of 0.2-500 microns, and intercepts large particle impurities.

◆2.The second stage is the folding filter element filter, high precision filtration, reduce turbidity, filtration accuracy 0.1-300 micron.

◆2.The second stage is the folding filter element filter, high precision filtration, reduce turbidity, filtration accuracy 0.1-300 micron.

Single bag and pneumatic diaphragm pump unit

The unit is composed of a single bag filter and pneumatic diaphragm pump. Group to be used for paint, resin, glue

and other high viscosity liquid filtration、

filling.

Single bag and electric pump unit

The unit is composed of a top - in single - bag filter and an electric pump. The top cover of the jacking bag filter is a casting cover with better sealing and bearing capacity.

Bag filter and self-cleaning filter Unit

◆

This unit is first passed through a pneumatic self-cleaning filter to intercept large particulate impurities and then into multi bag filter for secondary filtration.

◆

Mainly used for textile water, paper pulp, paint, emulsifier, adhesive, resin and other high viscosity liquid filtration.

Application scenarios

Pure water, beverage filter unit

Industrial water treatment filter machine

Paints and coatings filter machine

Grease filter machine

Shipping logistics

Contact Us

FAQ

1.Q: Are you a trading company or a manufacturer?

A: We are a manufacturer with manufacturing facilities like Plasma Welding Machine, CNC Machine, Polishing Machines etc. Our factory has been set up for 8 years. Our factory is located at Zhucheng City Shandong, which is near to Qingdao.

2.Q: How long is your delivery time?

A: Generally it is 15-30 days, Depends on your project.

3.Q:How can you control the quality and delivery?

A:Production strictly according to CE / ISO standards.

B:All our machines will be tested before packaging. wooden packing is strong and safety for long delivery.

4. Q:What s your warranty?

A:Our warranty is 1 year. But normally, our machine can work 5 years before repair.

5.Q: How do you ship the goods and how long does it take?

A: We usually ship by sea. DHL, TNT are also acceptable.

6.Q: What's your payment terms?

A: For small orders: 100% T/T in advance. For large orders: 30% T/T deposit 70% T/T balance before shipping.

7.Q: Can we get discount when make large orders?

A: Sure. More quantity, Better price.

8.Q: Can we use our own design?

A: Yes, OEM/ODM welcome. Please give us your requirements.

A: We are a manufacturer with manufacturing facilities like Plasma Welding Machine, CNC Machine, Polishing Machines etc. Our factory has been set up for 8 years. Our factory is located at Zhucheng City Shandong, which is near to Qingdao.

2.Q: How long is your delivery time?

A: Generally it is 15-30 days, Depends on your project.

3.Q:How can you control the quality and delivery?

A:Production strictly according to CE / ISO standards.

B:All our machines will be tested before packaging. wooden packing is strong and safety for long delivery.

4. Q:What s your warranty?

A:Our warranty is 1 year. But normally, our machine can work 5 years before repair.

5.Q: How do you ship the goods and how long does it take?

A: We usually ship by sea. DHL, TNT are also acceptable.

6.Q: What's your payment terms?

A: For small orders: 100% T/T in advance. For large orders: 30% T/T deposit 70% T/T balance before shipping.

7.Q: Can we get discount when make large orders?

A: Sure. More quantity, Better price.

8.Q: Can we use our own design?

A: Yes, OEM/ODM welcome. Please give us your requirements.

Hot Searches