Ultra-thin + lightweight + quick drying + waterproof + high strength + thin sticker, Created a new natural stone paving technology.Natural ultra-thin stone quick installation paving, The new process offers many advantages.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYMAN

-

Model Number:

-

KN

-

Material:

-

Natural marble + glass fiber, carbon fiber + waterproof cement

-

Colors:

-

Photo Showing

-

Thickness:

-

0.6-10mm

-

Surface:

-

High Glossy Polished

-

Size:

-

Customised Size

-

Packing:

-

Wooden Crates

Quick Details

-

Project Solution Capability:

-

graphic design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Villa

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYMAN

-

Model Number:

-

KN

-

Material:

-

Natural marble + glass fiber, carbon fiber + waterproof cement

-

Colors:

-

Photo Showing

-

Thickness:

-

0.6-10mm

-

Surface:

-

High Glossy Polished

-

Size:

-

Customised Size

-

Packing:

-

Wooden Crates

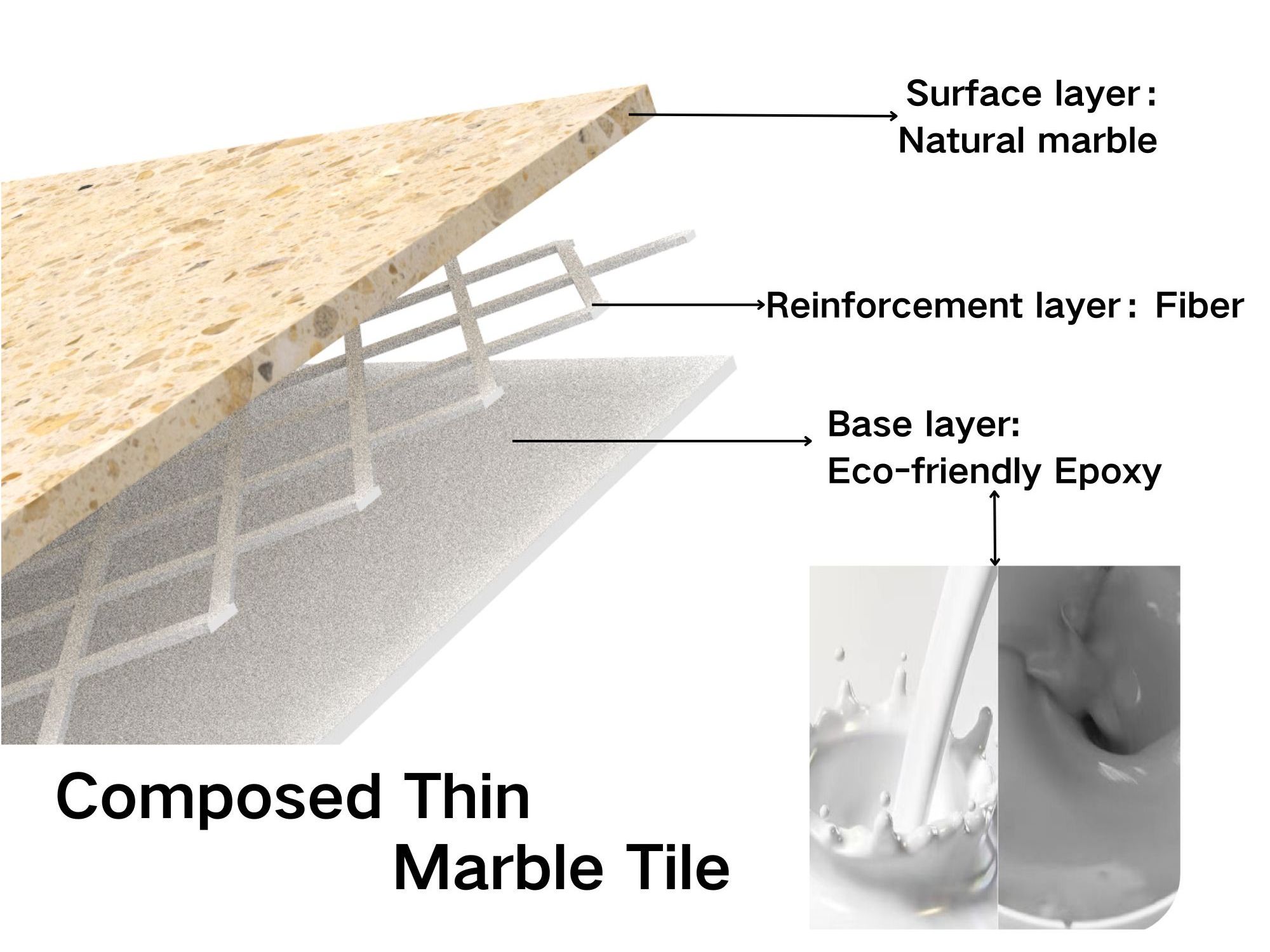

What is the

Ultra-thin marble slab ?

Ultra-thin marble slab is a new type of architectural decoration that combines ultra-thin natural stone slabs with a thickness of 0.1MM-8MM and reinforced materials such as glass fiber, carbon fiber, and aramid through special clay. Its comprehensive performance is greatly improved.

Product Description

Specification

|

item

|

value

|

|

Name

|

Natural ultra-thin marble sheet

|

|

Size

|

customizable

|

|

Application

|

Interior Wall decoration,Walls, floors, ceilings, furniture and appliances facades

|

|

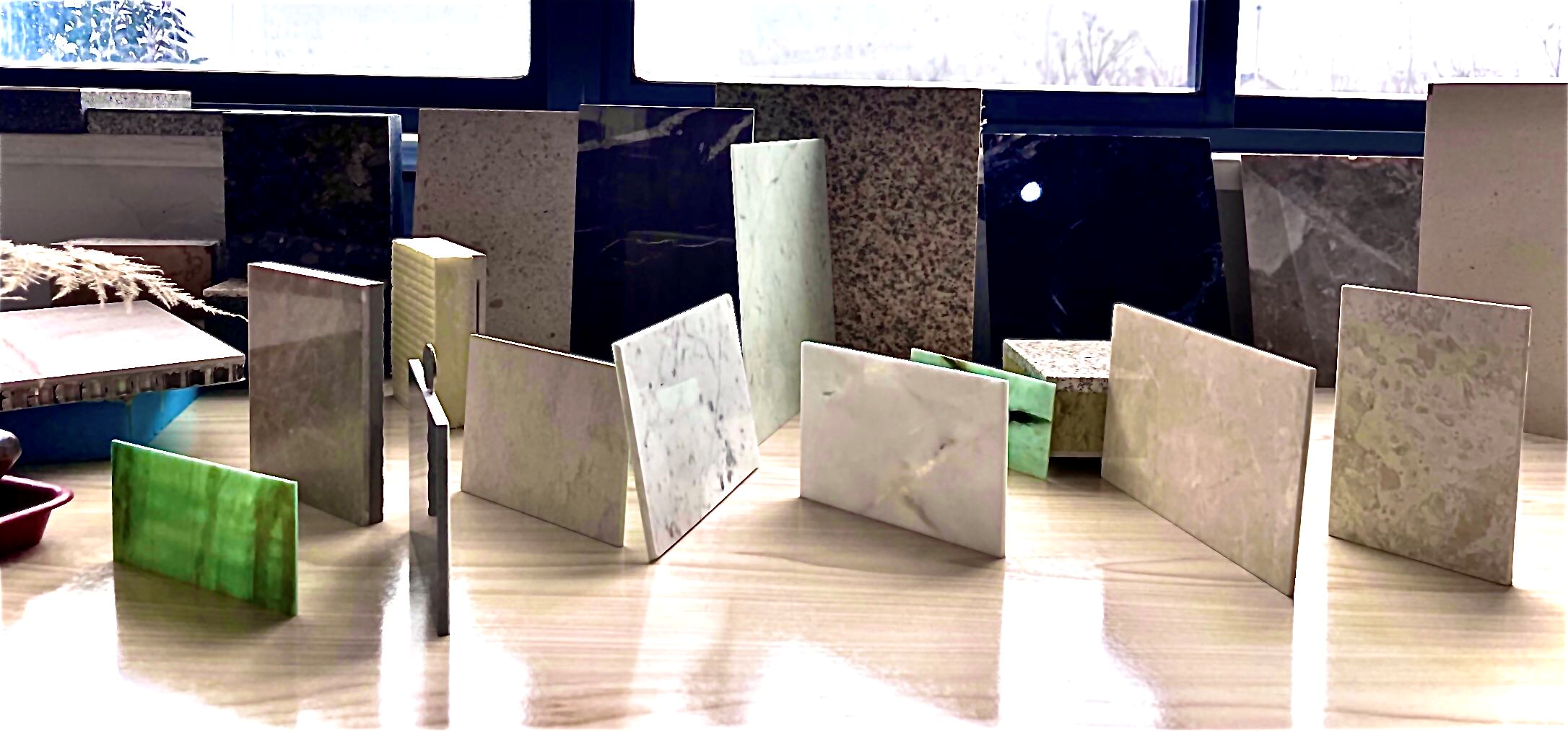

Color

|

Marble Pattern or as customized

|

Product advantages

As a new building material, ultra-thin marble slabs have upgraded the performance of traditional natural marble in many aspects and have many advantages.

1.Super impact resistance

Due to the comprehensive effect of the reinforcement layer, the cement layer and the optimal thickness setting, the ultra-thin marble slab has super impact resistance, ensuring that the KN slab is not prone to cracking and breakage during production, handling, installation and use.

2. Light weight loss

The weight is 3-15kg/㎡, which is only about 20% of traditional stone. The light weight reduction can derive many excellent properties. More convenient transportation and handling, efficient construction efficiency, more diverse wall options, and more worker-friendly paving

3. Cost advantage

Based on systematic cost optimization of main materials, auxiliary materials, transportation, secondary handling, labor, construction period, etc., the overall cost can be reduced by more than 30%.

4. Healthy and environmentally friendly

II More efficient resource utilization:

Mineral resource utilization increases by 4-8 times;

II More energy-saving production and transportation:

energy consumption in production and transportation is reduced by 80%;

II More environmentally friendly production process:

zero waste water and zero waste gas in the production process, and solid waste can be recycled;

II A healthier usage environment:

Use special, healthy and environmentally friendly clay to significantly reduce the damage caused by alkaline substances to stone and the environment;

II More environmentally friendly green material selection:

The main materials and auxiliary materials included are all green and environmentally friendly materials.

5. New paving

Ultra-thin + lightweight + quick-drying + waterproof + high-strength + thin paste, it creates a new natural stone paving process. Natural ultra-thin stone is quick to install and pave. The new process has many advantages.

Application

Hot Searches