- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINGBO

-

Voltage:

-

as the clients requirement

-

Dimension(L*W*H):

-

4.5*1.5*1.5m

-

Weight:

-

4500 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

certification:

-

ISO 9001:2008

-

color:

-

Any color

-

port:

-

XINGANG

-

control system:

-

PLC

-

use:

-

roof and wall

-

cutting:

-

hydraulic cutting

-

delivery time:

-

20 days

-

Spare parts:

-

easy damaged parts

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-25m/min

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINGBO

-

Voltage:

-

as the clients requirement

-

Dimension(L*W*H):

-

4.5*1.5*1.5m

-

Weight:

-

4500 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

certification:

-

ISO 9001:2008

-

color:

-

Any color

-

port:

-

XINGANG

-

control system:

-

PLC

-

use:

-

roof and wall

-

cutting:

-

hydraulic cutting

-

delivery time:

-

20 days

-

Spare parts:

-

easy damaged parts

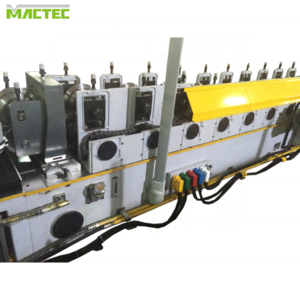

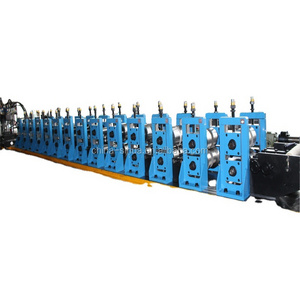

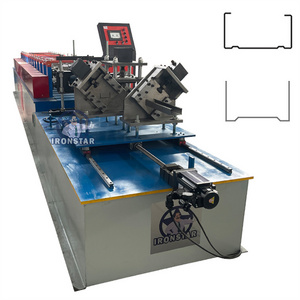

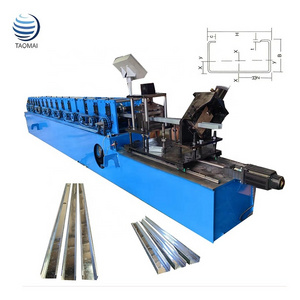

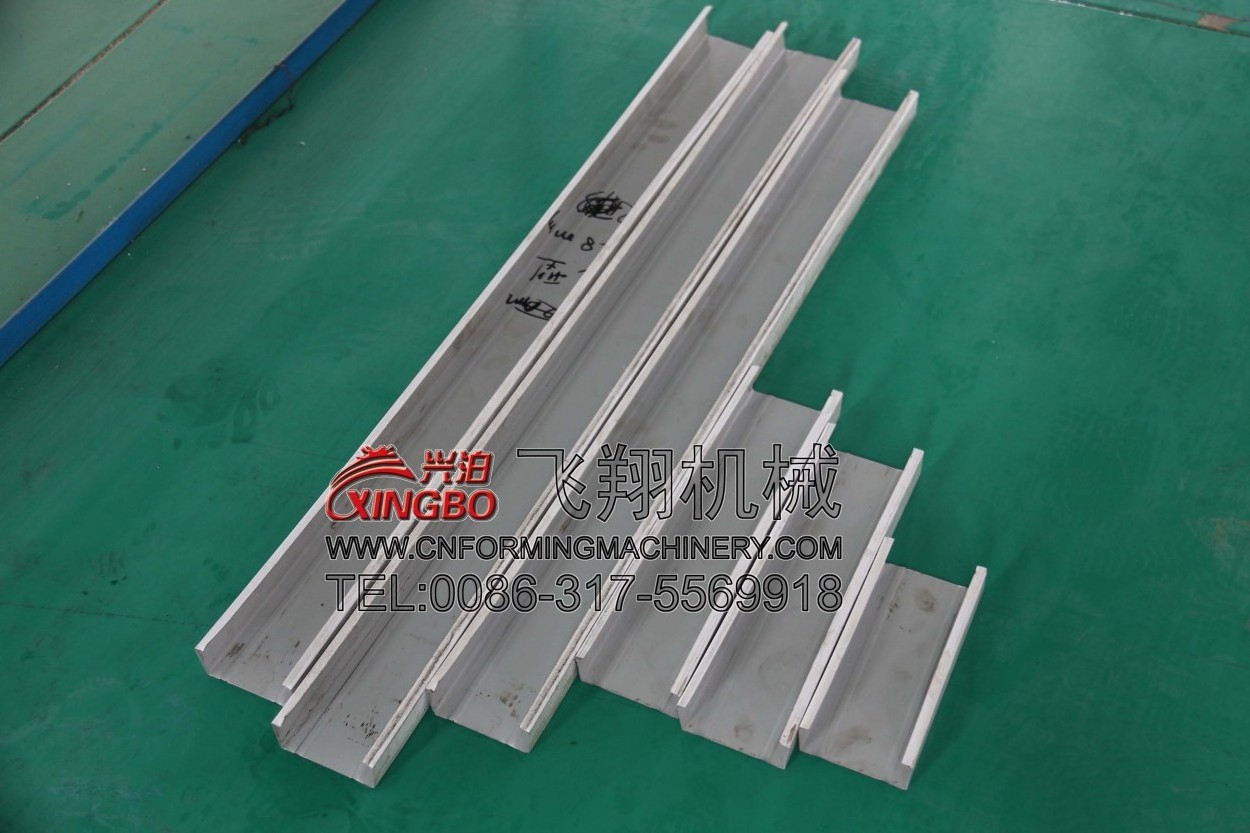

Gypsum ceiling metal studs and furring channel machines

Our credit:

1.The chart of process flow:

Decoiling--active feeding---forming---measuring lengh---punching---cutting---product to stand

2.Main equipment:

Decoiler,main forming machine,hydraulic cutting,electric system(plc),hydraulic system,product stand.

3.Technical parameters

1)Profile

thickness:

0.3--0.8mm or 1--2mm

thickness:

0.3--0.8mm or 1--2mm

2)inner tight decoiler

A.coil inner diameter:350mm--450mm

B.max width of coiling:400mm

C.max weight of loading:5000kg

3)main forming machine

A.Shaft material:45# steel,bearing steel outer diameter 85mm

B.Main motor power:5.5kw

C.Forming speed:25m/min

D.Voltage:380v,50hz

E.Roller station:15

4)cutting system

A.hydraulic cutter

B.Blade and mould material:Cr12 steel with quenched treated 60-62°

C.Cutting system advanced hydraulic drive,after automatic cutting after forming.no

5)control system

A.PLC: taida form Taiwan

B.Coder:from south korea

6)hydraulic system

A.advanced hydraulic system from taiwan

B.Power:3kw

4.Spare Parts

1).Easy damaged parts: conk 2 pcs, fuse-link 4 pcs

2).Rubber mat 1 pcs;

3).Bolt spanner 1 pcs

Terms:

1.Delivery:in stock

2.Package:export standard package for container

3.Payment:TT (30% by TT in advance,70% by TT after you inspect machine we need)

4.Delivery date:within 30 working days after receiving deposit

5.Products Warranty:12 month,and we will provide the technical support for whole life of the equipment.