- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fante

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

11

-

Weight (T):

-

0.63

-

Name:

-

Waste Palstic Crushing

-

Application:

-

Recycle Waste Plastic

-

Keyword:

-

Plastic Shredder

-

Usage:

-

Waste Plastic Cusher

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Product name:

-

Plactics Shredder Machine

-

Blades material:

-

9CrSi/D2/SKD-11/ Customized

-

Crushing material:

-

PET PE PP PVC

-

Mesh size:

-

8-40mm

-

After Sales:

-

After sales

Quick Details

-

Max.Production Capacity (kg/h):

-

700

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

500 - 700 kg/h

-

Brand Name:

-

Fante

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

11

-

Weight (T):

-

0.63

-

Name:

-

Waste Palstic Crushing

-

Application:

-

Recycle Waste Plastic

-

Keyword:

-

Plastic Shredder

-

Usage:

-

Waste Plastic Cusher

-

Function:

-

Plastic Cutter Grinder Crusher Shredder Machine

-

Product name:

-

Plactics Shredder Machine

-

Blades material:

-

9CrSi/D2/SKD-11/ Customized

-

Crushing material:

-

PET PE PP PVC

-

Mesh size:

-

8-40mm

-

After Sales:

-

After sales

|

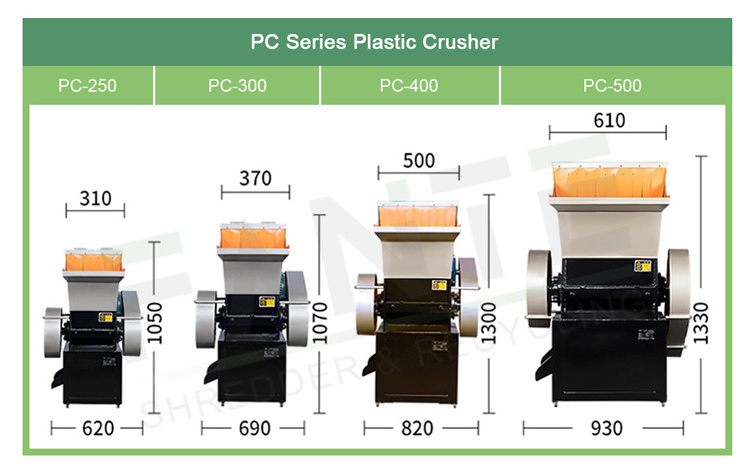

Model

|

PC-250

|

PC-300

|

PC-400

|

PC-500

|

|

Motor power(kw)

|

4

|

4

|

7.5

|

11

|

|

Mainshaft spped(rpm)

|

570

|

570

|

570

|

550

|

|

Rotating Diameter(mm)

|

200

|

200

|

300

|

300

|

|

Rotating balde(pcs)

|

3

|

3

|

3

|

6

|

|

Fixed blade(pcs)

|

2

|

2

|

2

|

2

|

|

Feed port size(mm)

|

310*170

|

370*170

|

500*205

|

610*225

|

|

Feed port height(mm)

|

900

|

930

|

1120

|

1135

|

|

Screen diameter(mm)

|

⌀8

|

⌀8

|

⌀10

|

⌀10

|

|

Weight(kg)

|

160

|

185

|

368

|

470

|

|

Dimension(mm)

|

910*620*1050

|

910*689*1070

|

1120*820*1300

|

1280*930*1330

|

|

Model

|

PC-5060

|

PC-5070

|

PC-5080

|

PC-50100

|

|

Motor power(kw)

|

15

|

18.5

|

22

|

30

|

|

Rotating Diameter(mm)

|

460

|

460

|

460

|

460

|

|

Rotating balde(pcs)

|

6

|

6

|

6

|

6

|

|

Fixed blade(pcs)

|

4

|

4

|

4

|

4

|

|

Feed port size(mm)

|

620*470

|

720*470

|

820*470

|

1000*470

|

|

Feed port height(mm)

|

1410

|

1415

|

1430

|

1500

|

|

Screen diameter(mm)

|

⌀14

|

⌀14

|

⌀16

|

⌀16

|

|

Weight(kg)

|

860

|

980

|

1180

|

1600

|

|

Dimension(mm)

|

1360*1180*1846

|

1470*1280*1860

|

1520*1380*1880

|

1800*1750*2200

|

◼︎

High efficiency:large diameter crusher typically have a large working capacity and can handle a large amount of raw materials,thereby improving production efficiency.

◼︎

Good crusher effect:this type of crusher can ebenly and finely crush raw materials to produce the required size,ensuring product quality.

◼︎

Low energy consumption:although large diameter crusher typically require a large power input,due to their high efficiency,they can complete crushing tasks in a relatively short time,thereby reducing overall energy consumption.

◼︎

Low maintenance cost:these machines are usually designed to be sturdy and durable,able to operate for long periods of time without the need for frequent maintenance,reducing maintenance costs.

◼︎

High degree of automation:many large diameter crusher can be untegrated into automated production lines to. achieve automatic control and monitoring,improving the stability and controllability of production.

◼︎

Environmental protection:some large diameter crusher use advanced duct control technology to reduce dust emissions and help protect the environment.

◼︎

Flexibility:these machines can be sdjusted asd needed to adapt yo different materials and production requiremennts.

01.Thicken the skin to block the material

Thickening the curtain effectively prevents the material from splashing out when the machine breaks it.

02.Customizable screen

The discharge size depends on the mesh size,making rhe selection more flexivle.

03.Motor

The crusher motor adopts a full copper core motor to reduce energy consumption and have a longer series life.

04.Large diameter flywheel

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches