INSTRUCTION

•

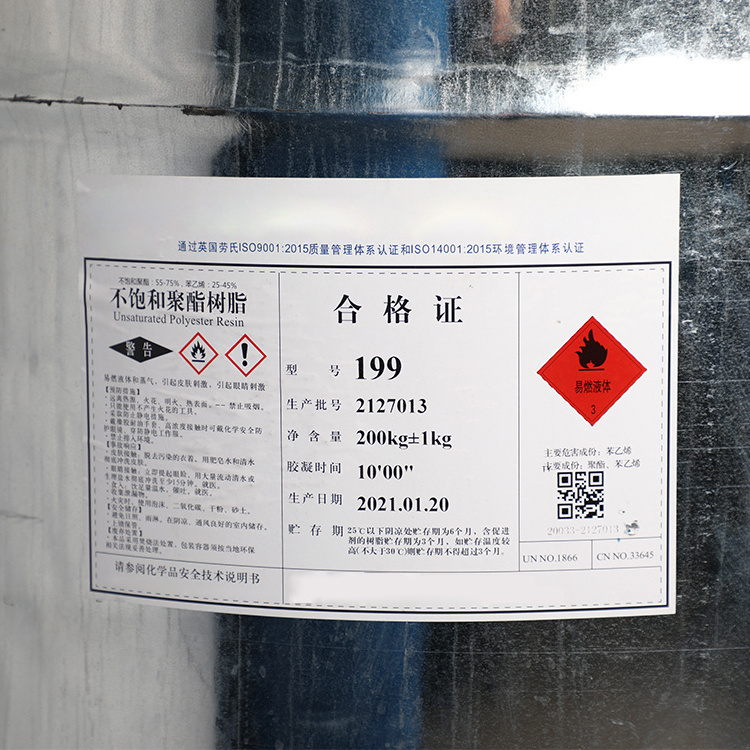

DC191 resin contains wax, does not contain accelerators and thixotropic additives.

• DC191 resin is sensitive to light and easily gels when exposed to light, so avoid opening the package or exposing it to strong light before use.

• Recommended curing system: pure diamond accelerator 0.4-2. 0% (colorless accelerators containing copper and potassium salts are not recommended), MEKP curing agent 1.0-2. 5%o

• The performance of DC191 resin glass fiber reinforced plastic has the characteristics of high hardness and good heat resistance. If the product has toughness requirements or the production process conditions are limited, it is recommended to choose phthalic 191 resin.

- Product Details

- {{item.text}}

Quick Details

-

MF:

-

C8H4O3.C4H10O3.C4H2O3

-

EINECS No.:

-

208-750-2

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

CQDJ

-

Model Number:

-

Type - DC191

-

Product name:

-

UPR(unsaturated polyester resin)

-

Material:

-

Resin

-

Color:

-

light yellow transparent

-

Acidity:

-

17-23 mgKOH/g

-

Characteristic:

-

thick liquid

-

Appearance:

-

Light Yellow

-

Gel time:

-

5.0-18.0min

-

Heat stability:

-

≥24 h

-

Viscosity:

-

0. 25-0. 45 Pa.s

Quick Details

-

CAS No.:

-

26123-45-5

-

Purity:

-

68-75

-

Other Names:

-

Unsaturated Polyester Resin

-

MF:

-

C8H4O3.C4H10O3.C4H2O3

-

EINECS No.:

-

208-750-2

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

CQDJ

-

Model Number:

-

Type - DC191

-

Product name:

-

UPR(unsaturated polyester resin)

-

Material:

-

Resin

-

Color:

-

light yellow transparent

-

Acidity:

-

17-23 mgKOH/g

-

Characteristic:

-

thick liquid

-

Appearance:

-

Light Yellow

-

Gel time:

-

5.0-18.0min

-

Heat stability:

-

≥24 h

-

Viscosity:

-

0. 25-0. 45 Pa.s

Products Description

|

ITEM |

Range |

Unit |

Test Method |

|

Barcol hardness

|

66

|

|

GB/T 3584-2005

|

|

Tensile strength

|

330

|

MPa

|

GB/T 1449-2005

|

|

Tensile modulus

|

17000

|

MPa

|

GB/T 1449-2005

|

|

Flexural Strength

|

330

|

MPa

|

GB/T 1447-2005

|

|

Flexural modulus

|

17000

|

MPa

|

GB/T 1447-2005

|

General Type - DC191

UPR

APPLICATION

• Suitable for the fabrication methods e.g. filament winding, hand lay-up, pultrusion.

• Widely used for the fabrication of common FRP tanks, pipes,and stone repair and enhancement,ect

More products

About Us

Production Line

Certifications

Shipping & Packing

FAQ

Q1:Are you a factory? Where are you located?

A: We are a professional manufacturer with more than 20 years production experience of composite materials, Our own factory locate in Chendu city, Sichuan province.

Q2:What's the MOQ?

A: Usually 1 Ton, depend on what products you need.

Q3:Package & Shipping.

A: Normal package:by carton, we accept OEM packing.

Q4:When can I offer?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or tell us in your email , so that we can reply you priority.

Q5:How do you charge the sample fees?

A: If you need a samples from our stock, we can provide to you for free, but the free charge should be on your side. If you need a special size, We will charge the sample making fee which will be refund when you place an order.

Q6:What's your delivery time for production?

A:If we have stock , can delivery in 1-7 days ; if without the stock, need 5-30 days, depend on quantity.

Contact Us

Hot Searches