- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Hotel

-

Design Style:

-

EUROPEAN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SUNSHINE

-

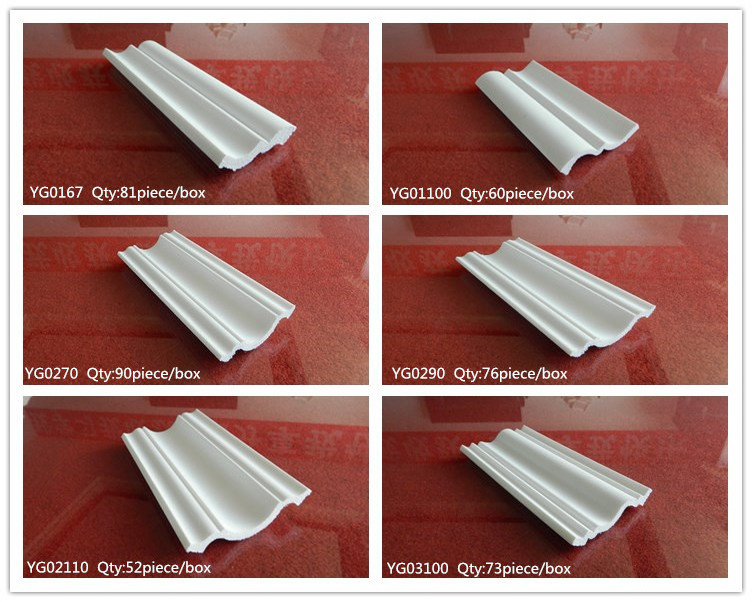

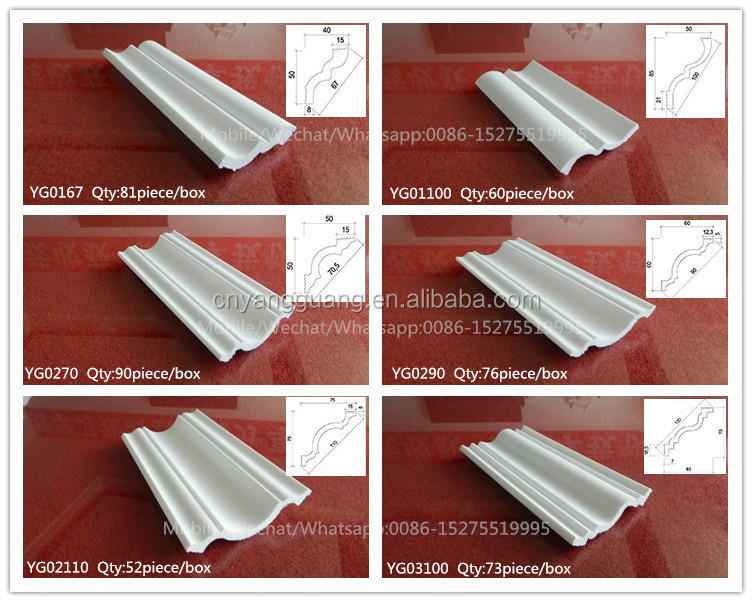

Model Number:

-

YG03

-

Raw material:

-

GPPS

-

Width:

-

30-150mm

-

OEM:

-

YES

-

Packing:

-

Box

-

Color:

-

White

-

Density:

-

40-100kg/m3

-

Advantage:

-

Lightweight

-

Type:

-

YG03

-

Surface:

-

smooth

-

Style:

-

European\Modern\Middle East\Africa

Quick Details

-

Warranty:

-

NONE

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design, total solution for projects

-

Application:

-

Hotel

-

Design Style:

-

EUROPEAN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SUNSHINE

-

Model Number:

-

YG03

-

Raw material:

-

GPPS

-

Width:

-

30-150mm

-

OEM:

-

YES

-

Packing:

-

Box

-

Color:

-

White

-

Density:

-

40-100kg/m3

-

Advantage:

-

Lightweight

-

Type:

-

YG03

-

Surface:

-

smooth

-

Style:

-

European\Modern\Middle East\Africa

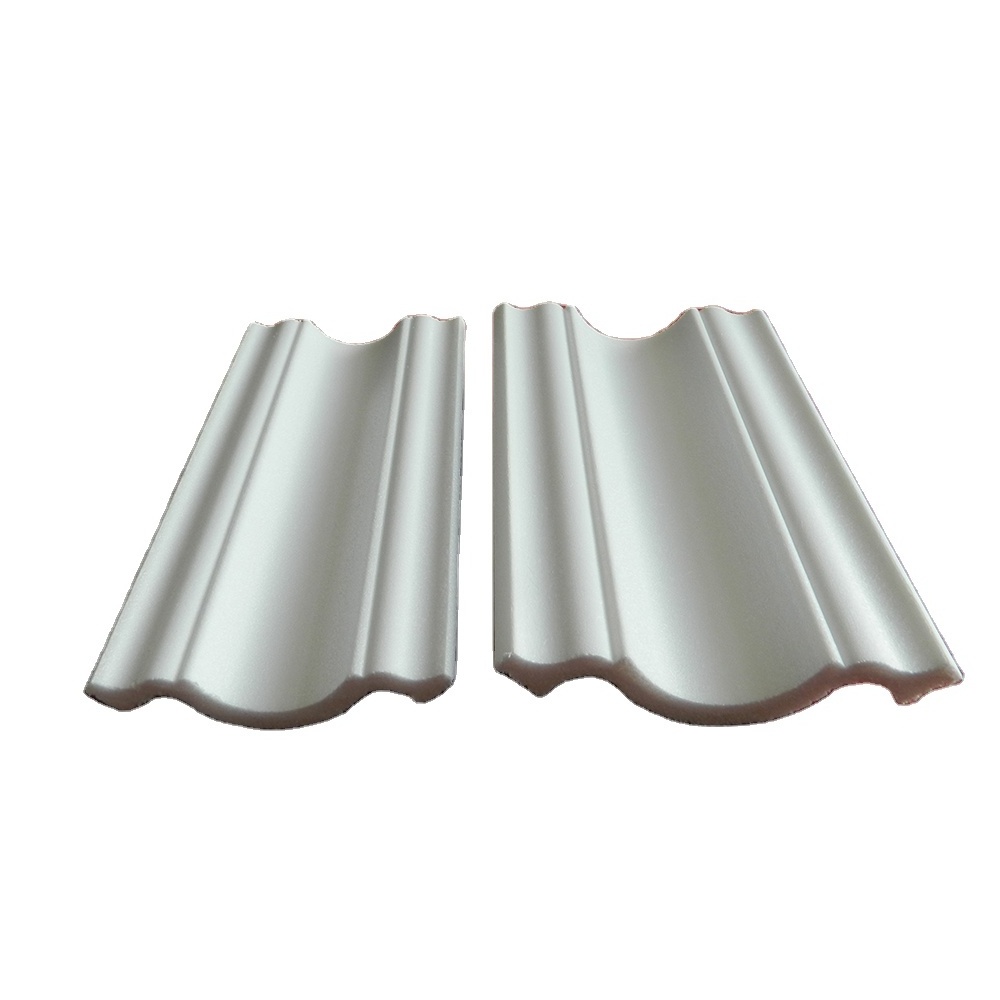

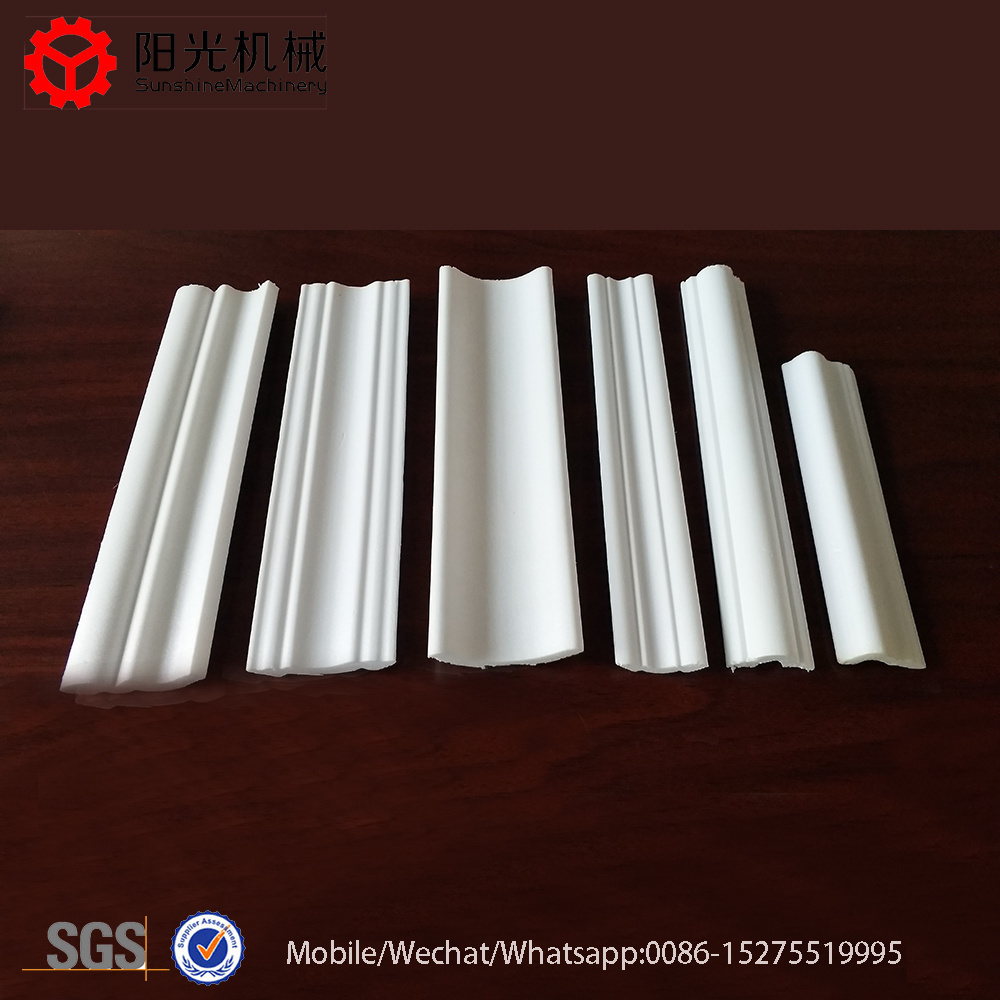

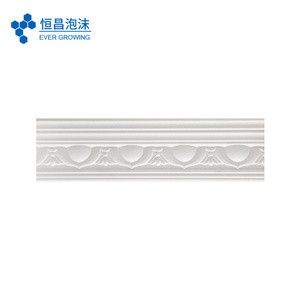

Polystyrene cornice crown moulding

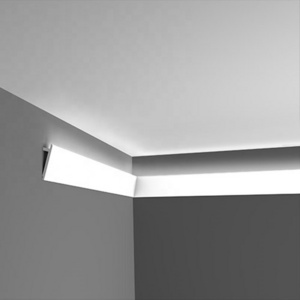

Foam Design Center StyroFoam moldings are easy to install and light weight. They are even used by some crown molding professionals and home builders across the country. It is extremely popular in Europe as well.

The XPS foam cornice are light and easy to install by yourself with Acrylic cornice Adhesive ,Gone are the days of hammer,nails and blue fingers .this products have more advantage ,for example :thoughness ,resist water absorption ,lightweight and could recycling .it is really a new super quality environmental decorativ material.

The cornice products MOQ:10000m

The Delivery time :Within 30 working days after receipt of the down payment

1 Polystyrene comes in many different grades. What type do you use for for your cornices?

All our cornices are manufactured from blocks of virgin 20DV flame retardant polystyrene.

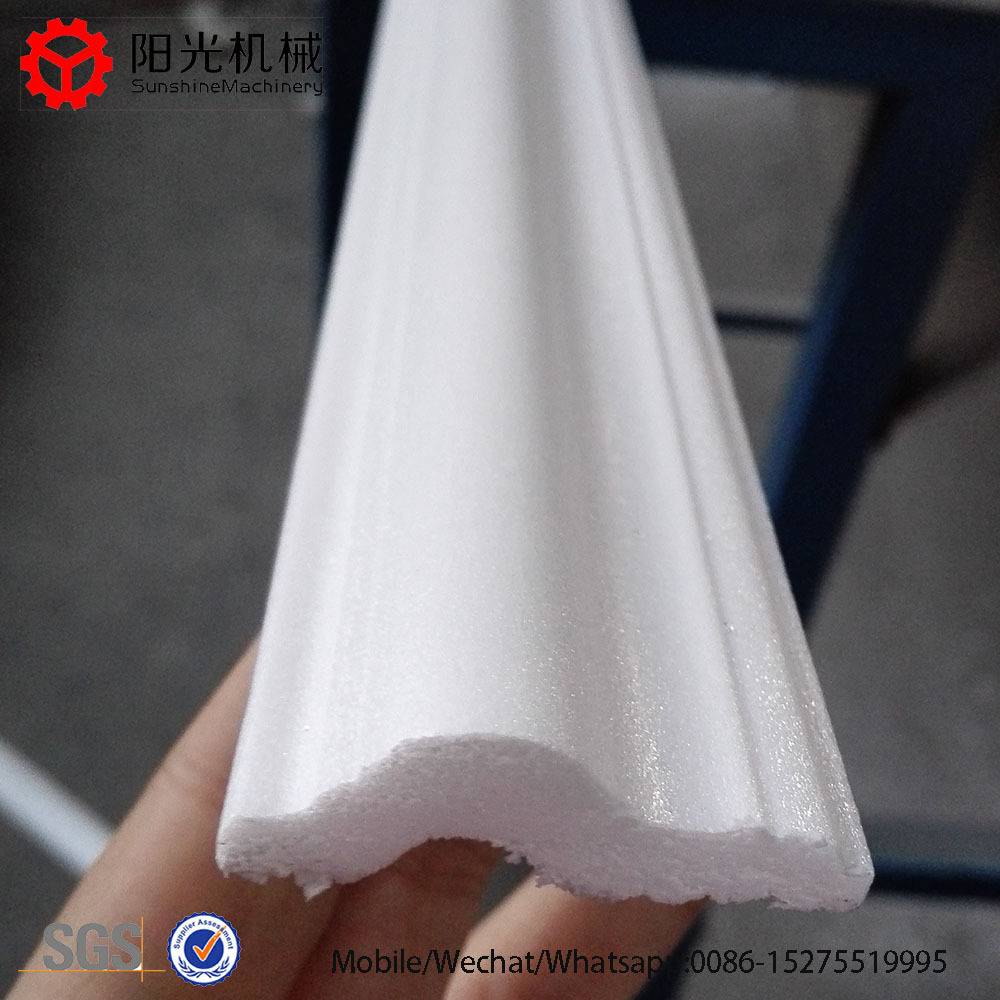

2 Is handling prior to installation a problem with something as easily damaged as polystyrene?

The finished cornices remain in the blocks of polystyrene from which they are cut until ready for use. These

blocks provide protective packaging and facilitate transport and storage because they may be stacked flat or

upright. A typical block holding 100 metres of cornice weighs less than 10kgs and is easily handled by one person.

3 What paint can be used on the cornices?

An approved, good quality primer coat or undercoat is applied to the installed cornice before finishing with any water-based paint. Paints containing chemical solvents should normally be avoided as these could damage the polystyrene. (Certain solvent-based paints may be used – but check with us first!)

4 How long will the cornices last:

Because they are made from plastic, the cornices will last indefinitely under normal conditions.

5 Will the cornices be damaged if the roof leaks?

No – polystyrene is not generally affected by contact with water.