- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Poplar Soild Wood

-

Color:

-

Natural Color

-

Grade:

-

AA AB BB

-

Moisture content:

-

6%-12%

Quick Details

-

Place of Origin:

-

China

-

Product name:

-

Buy Wholesale Price Paulownia Wood For Sale

-

Usage:

-

Furniture

-

Material:

-

Poplar Soild Wood

-

Color:

-

Natural Color

-

Grade:

-

AA AB BB

-

Moisture content:

-

6%-12%

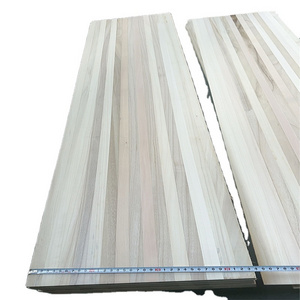

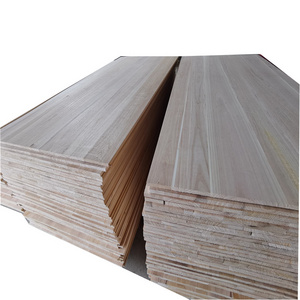

Paulownia Wood

When you walking near the Paulownia wood boards, the gracile rays and beautiful grains on the surfaces will catch your eyes. Putting your hands on the wood surface , you can get the very smoothly feelings more like the silk but warm. Taking a deep breath, you can not smell any odor from the wood boards.

Some Useful Data of the Paulownia Wood

Average Dried Weight: 18 lbs/ft 3 (280kg/m 3 )

Janka Hardness: 300lb f (1,330N);

Modulus of Rupture: 5,480lb f /in 2 (37.8MPa);

Elastic Modulus: 645,000lb f /in 2 (4.38GPa);

Crushing Strength: 3,010lb f /in 2 (20.7MPa);

Shrinkage: Radial 2.4%, Tangential 3.9%,

Volumetric 6.4%, T/R Ratio:1.6

Head Rig

The primary saw cuts the logs into sawn pieces or boards,

Edging

Removes irregular edges and defects from sawn pieces or boards.

Trimming

The trimmer squares off the ends of lumber into uniform pieces.

Rough Lumber Sorting

Pieces or Boards are separated based on dimension and final product production, whether the finished pieces or boards will be unseasoned(kown as "green") or dry.

Stickering

Lumber destined for kiln drying production is stacked with spacers(known as stickers) that allow air to circulate within the stack(Green product skips this stage and the next).

Drying

Kiln Drying wood speeds up the natural evaporation of the wood's MC in a controlled environment.

Gluing

Gluing the side of the uniform pieces and Splicing them together.

Pressing

The Spliced pieces will be getting thought the pressing process for ensuring all the glued pieces be stable.

Sanding

Smooths the wood's surfaces and ensures that each boards or pieces has a uniform thickness, all the surfaces of the boards or pieces will be sanding by the airbag sanders with the sand belts of P60/P180/P240 or as customized(P60 belts can keep the wood grains well; P180 belts for the very smooth surfaces, P240 belts for the perfect surfaces applying to the printing process).

MC Test and Grading

Assigns a "grade" to each board that indicates its quality level, based on a variety of characteristics, including its MC.

Sealing and Storage

After Grading, all the Boards will be sealed and stored into the Finished Goods Warehouse.

Careful Packaging

Specialized Sealing Films

are sealed on the six surfaces of the boards package.

Thicker Corrugated Papers

are packaged Six-Sides for protecting all of the faces and angles.

Three/Five-Lays Plywood Boards

are packed Six-Sides for resistance from outside.

Toughness Packing Belts

are strapping strongly on the outside of the Package.

Stronger Wood Pallets

at the bottom for making the Unloading easier for shipment receiving.

Fast Delivery

3 km

distance of the national road from our Factory to the High-Way Entry.

30 container trailers

or more we can arrange for the delivery.

500 km

distance of the national high-way road from our factory to the Qingdao Port.

5 hours

or less transport time, the cargo can be delivered to the Port for the shipment.

Cao County Jiusi Woods Co., Ltd locates at Cao County, Heze city, Shandong Province.

Through over 20 years' development,we have become a very professional manufacturer engaging in the fields of all kinds of wooden products,including various wooden crafts and edge glued boards,finger jointed panels,blockboards,plywood,etc.The materials we use are abundant, such as paulownia,pine,China fir,cedarwood,bamboo,birch,poplar, beech,oak,acacia, etc.

Over 20 years' professional experience of all kinds of wooden products

Best Service with fast delivery and years of exporting experience