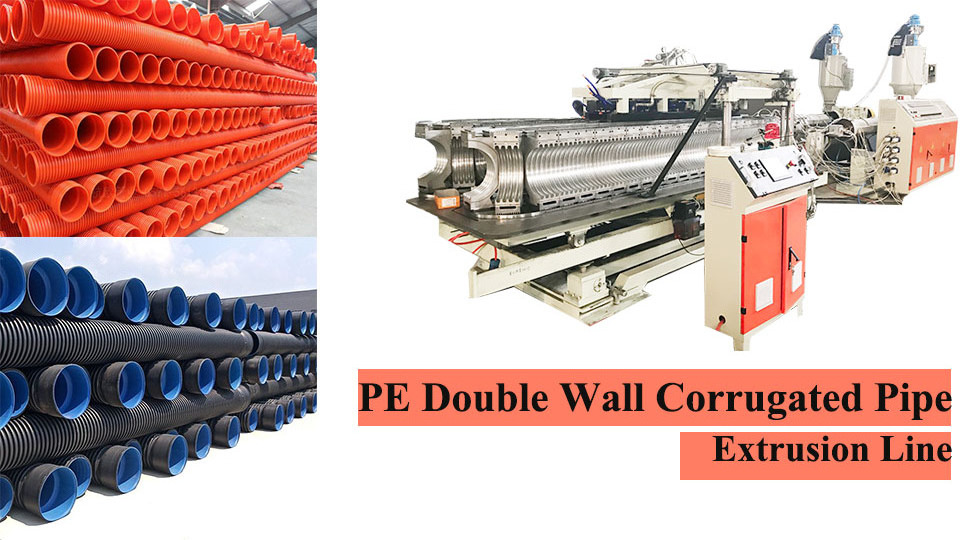

Raw material is PE/PP/PVC granule/pellets.

Machine has the features of high automatic , stable performance, high output, and easy operation.

|

No

|

Items

|

Quantity

|

|

1

|

Single Screw Extruder

|

one or two units

|

|

2

|

Extrusion Mould

|

as requst

|

|

3

|

Shaping Platform

|

one units

|

|

4

|

Shaping dies

|

as diameter

|

|

5

|

Winder

|

1 uint

|