- Product Details

- {{item.text}}

Quick Details

-

length:

-

customizable

-

weight:

-

2-4.2kg/m2

-

surface treatment:

-

hot stamping

-

colors:

-

more than 300 Kinds

-

MOQ:

-

one 20ft

-

Thickness:

-

6-12mm

-

Material:

-

PVC Resin

-

Product name:

-

pvc ceiling panel

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

color&design:

-

customizable

-

width:

-

595mm

-

length:

-

customizable

-

weight:

-

2-4.2kg/m2

-

surface treatment:

-

hot stamping

-

colors:

-

more than 300 Kinds

-

MOQ:

-

one 20ft

-

Thickness:

-

6-12mm

-

Material:

-

PVC Resin

-

Product name:

-

pvc ceiling panel

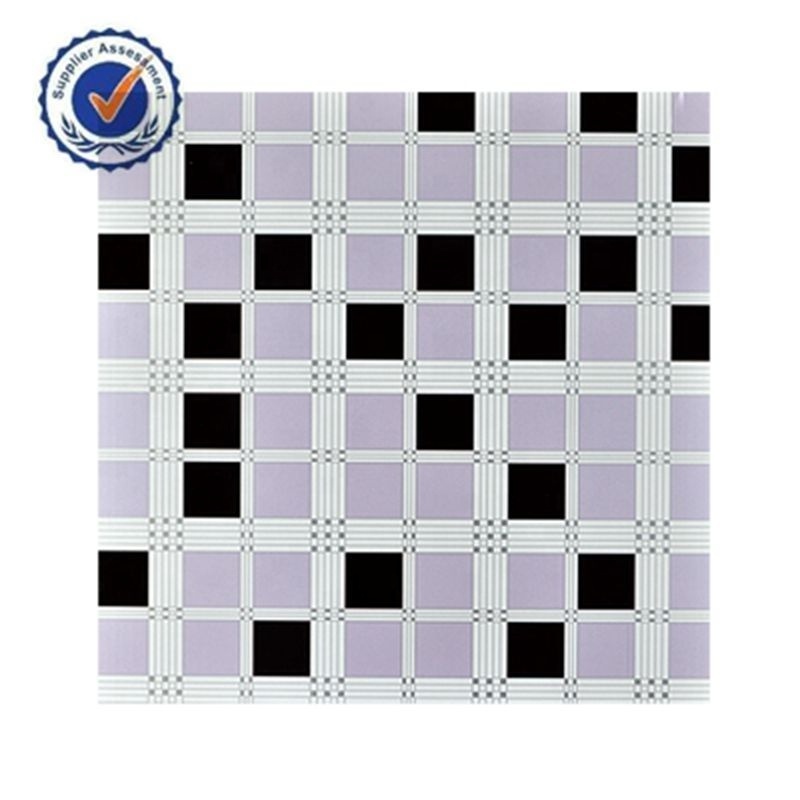

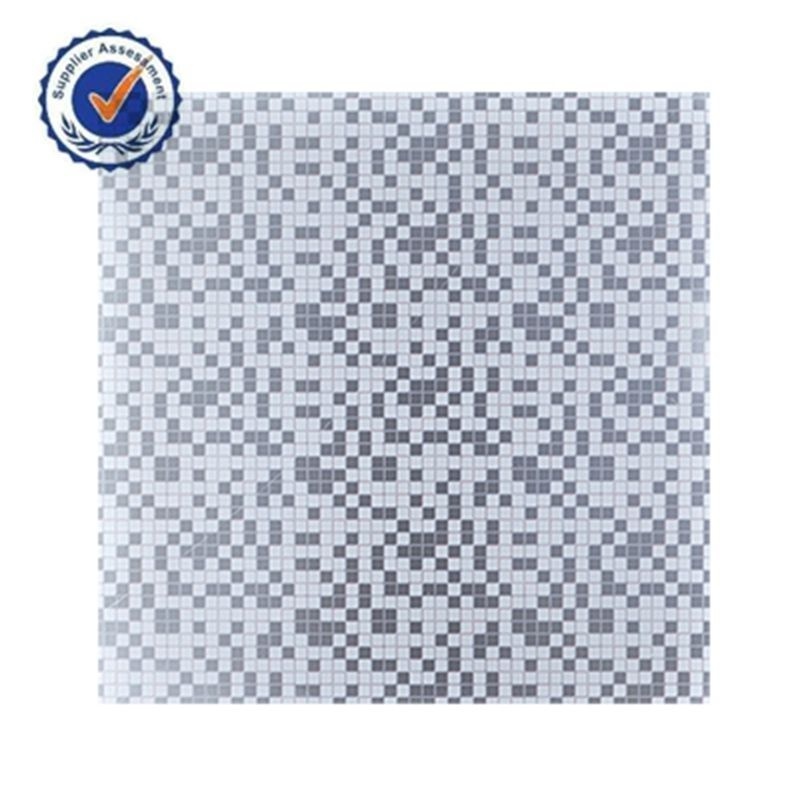

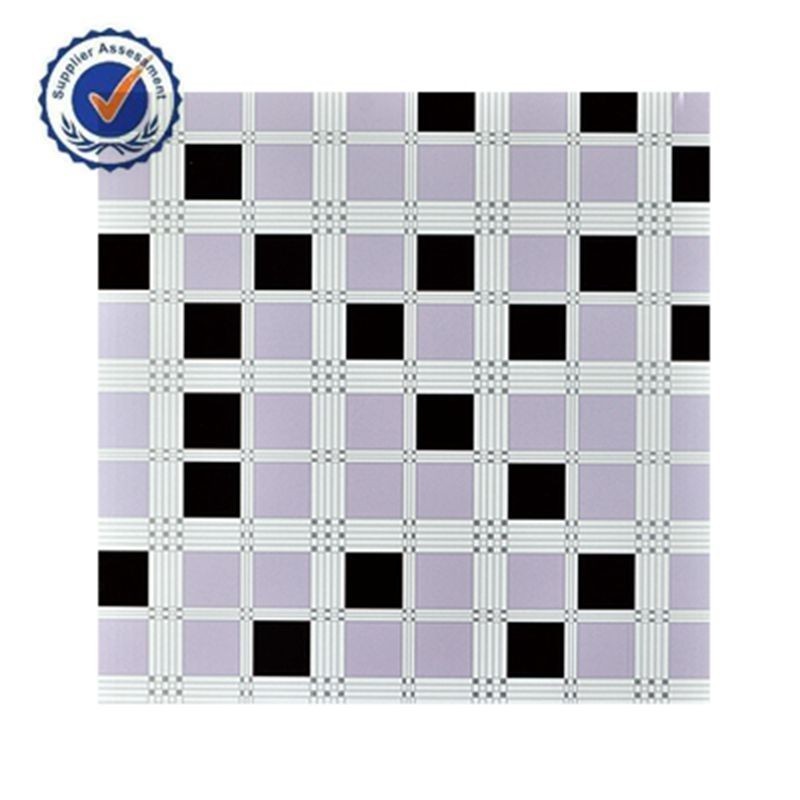

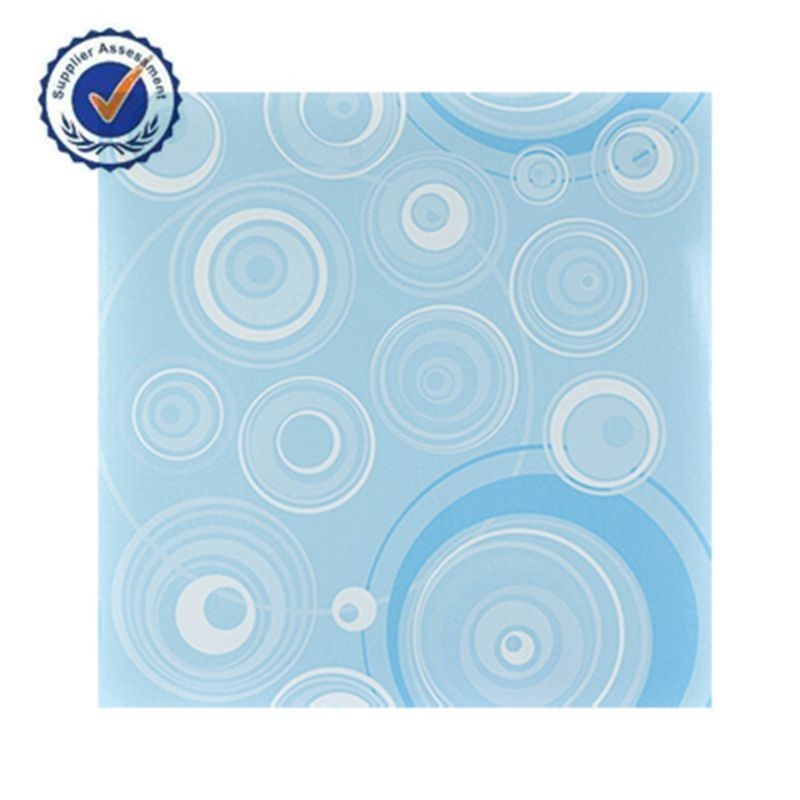

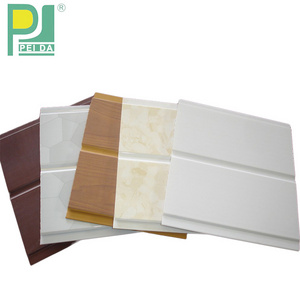

PVC 595mm size ceiling panels

The PVC ceiling widely used for indoor decorative, such as Hotels, commercial buildings, hospitals, schools, cooking rooms, washing rooms etc.

The features of Hot stamping PVC 595mm size ceiling panels

1) Easily assembly and clean

2) Without gap when concatenated

3) High intensity, corrode-resisting, aging-resisting

4) Due to PVC's high chemical stability,our panels can be used more than 10 years

5) Prevent fire,water,antibiotic.

6) Harmless to human being and eco-friendly

7) For Ceiling and Wall decoration

8) Accessories(corners) accompany perfectly

Width: 59.5cm

Thickness: 7mm

Length: 5.85m for 20GP container, 5.95m for 40HQ container or according to customers' requirement

Color: more than 300 colors meet your needs

according to clients' requirements

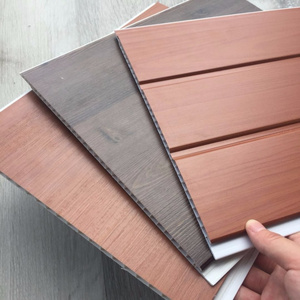

Design: Groove, Flat

PVC ratio: 40-50% according to clients' requirements

About Us

Experienced building material manufacturer supplier

Service

Stable product quality , in time supply, good faith management and your private products consultant

Equipment & Technology

Good quality & best price

Installation

1. Select the first board and fix it onto the wooden framework.

2. Use a special designed connector to fasten the next board.

3. Fix the next board onto the wooden framework.

4. Continue this step until you hit the end of the ceiling.

10 easy steps to a complete makeover:

Step 1: Secure a corner support rail with nails, stapler guns, screws, liquid nails, etc so that it is securely fastened

Step 2: Fasten the top and bottom support rails.

Step 3: Cut the panels to size using a handsaw, electric saw or sharp blade.

Step 4: Slide the panel in at the top support rail and ease it into the bottom support rail.

Step 5: Make sure the first panel is attached securely to the corner.

Step 6: Take the next panel and repeat Step 4.

Step 7: Slide the panel to the previous panel making sure the tongue locks securely with the groove.

Step 8: Repeat Step 6 and Step 7 until you reach the end.

Step 9: If required, cut off any access to fit.

Step 10: Install a support rail to complete the installation.

Plastic Film Packing

Usually we packed it by plastic film and 10pcs per bundle,quantity of one bundle can also be adjusted as your request

Carton Packing

Carton packing can also as one of your choice,but the price will be little higher than the plastic film type

Delivery

Usually a 20ft container can be finished within 2 weeks and 3 weeks for a full 40ft container order.

Printing color

can be flat/groove on surface

Hot stamping color

Laminated color

can be flat/groove on surface

PVC panels with grooves

grooves with laminated film

PVC panels with a line

black /silver/golden line/shining silver/golden silver lines for chosen

Accessoires for PVC panels

cornice/H jointer/clips/other accessoires etc.