- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

YJ-FS02

-

Machine name:

-

waterproof seal plug inserting cable terminal crimping machine

-

Applicable wire size:

-

AWG28~AWG14

-

Function:

-

wire cut, both sides stripping&crimping and one side wire sealing

-

weight:

-

440kg

-

cutting length:

-

50~9999mm (can be customized)

-

stripping length:

-

10mm

-

suitable terminals:

-

cross-feed terminals, direct-feed terminals, flag-shaped terminals

-

Power supply:

-

220V 50/60Hz (110V can be customized)

-

Capacity:

-

2000-3000 pieces/hour

-

Warranty:

-

1 Year

Quick Details

-

Use:

-

Crimping

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

YongJia

-

Model Number:

-

YJ-FS02

-

Machine name:

-

waterproof seal plug inserting cable terminal crimping machine

-

Applicable wire size:

-

AWG28~AWG14

-

Function:

-

wire cut, both sides stripping&crimping and one side wire sealing

-

weight:

-

440kg

-

cutting length:

-

50~9999mm (can be customized)

-

stripping length:

-

10mm

-

suitable terminals:

-

cross-feed terminals, direct-feed terminals, flag-shaped terminals

-

Power supply:

-

220V 50/60Hz (110V can be customized)

-

Capacity:

-

2000-3000 pieces/hour

-

Warranty:

-

1 Year

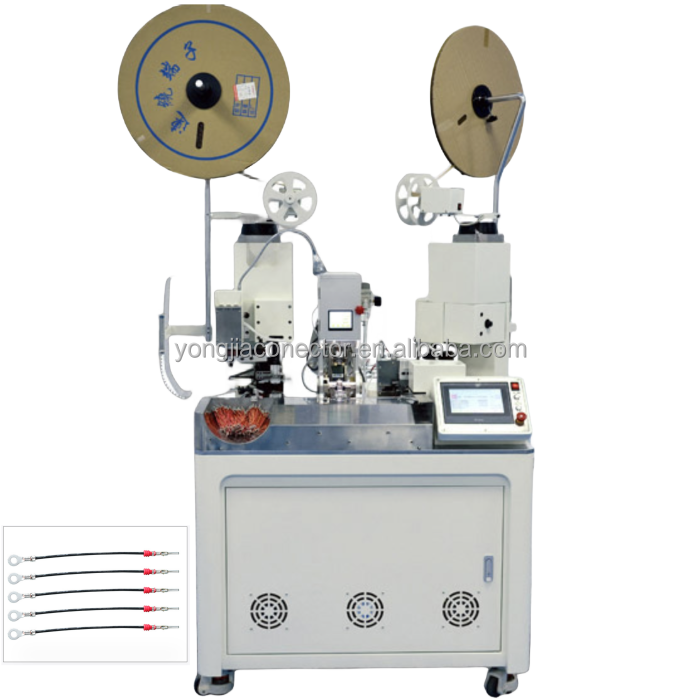

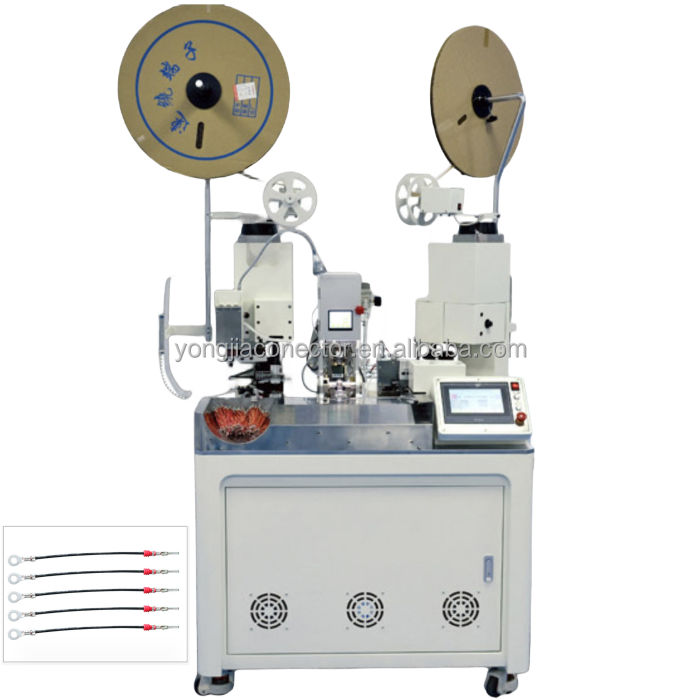

Fully automatic waterproof seal plug inserting cable both sides terminal crimping machine

Fully automatic waterproof seal plug inserting cable both sides terminal crimping machine

Features:

1. This is an economical wire double-sided terminal terminal and single-head waterproof plug inserting terminal machine,

which integrates functions such as wire cutting,stripping, inserting waterproof plugs, and crimping terminals.

The waterproof plug is automatically fed through the automatic feeding system. One machine can process a variety of different products.

When replacing the waterproof plug, you only need to replace the corresponding track fixture, and the product switching can be completed within a few minutes.

2. This wire terminal machine is integrally formed with nodular cast iron, the whole machine has strong rigidity, and the

crimping is stable. The default crimping stroke is 30mm, and the standard OTP bayonet mold is used.

In addition, a model with a stroke of 40mm can also be customized, and various European molds can be used.

It can also be equipped with a terminal crimping force monitor to monitor the pressure curve changes of each crimping process in real time,

and automatically alarm and stop when the pressure is abnormal.

3. Color touch screen operation interface, parameter setting is intuitive and easy to understand, parameters such as

cutting length, stripping length, inserting waterproof plug position, crimping position and other parameters can be set in the program.

Each functional module can be freely opened or closed in the program, for example, the function of inserting the waterproof plug

can be closed to use the machine as a double-sided automatic terminal machine. The program memory function can save

the processing parameters of different products into different program numbers, and the corresponding crimping parameters

can be called out with one key when switching products.

Specifications of Fully automatic waterproof seal plug inserting cable both sides terminal crimping machine:

|

Applicable wire diameter |

AWG28~14

|

|

Cutting length |

50~9999mm (can be customized)

|

|

Stripping length |

≤10mm (can be customized) |

|

Cutting accuracy |

±(0.5+L*2%) L=cutting length |

|

Maximum pressure |

2T(3T models can be customized) |

|

Crimping stroke |

30mm (40mm stroke model can be customized) |

|

Applicable terminals |

cross-feed terminals, direct-feed terminals, flag-shaped terminals, etc. |

|

Production efficiency |

2000~3000 pieces/hour |

|

Operation interface |

color touch screen |

|

Air pressure |

0.5~0.8Mpa |

|

Rated power |

2500W

|

|

Working voltage |

220V 50/60Hz (110V can be customized) |

|

Dimensions |

800*1000*1500mm

|

|

Net weight |

about 440kg |

|

Optional configuration |

long wire conveyor belt, safety shield, terminal pressure monitor, visual inspection system, servo terminal machine |

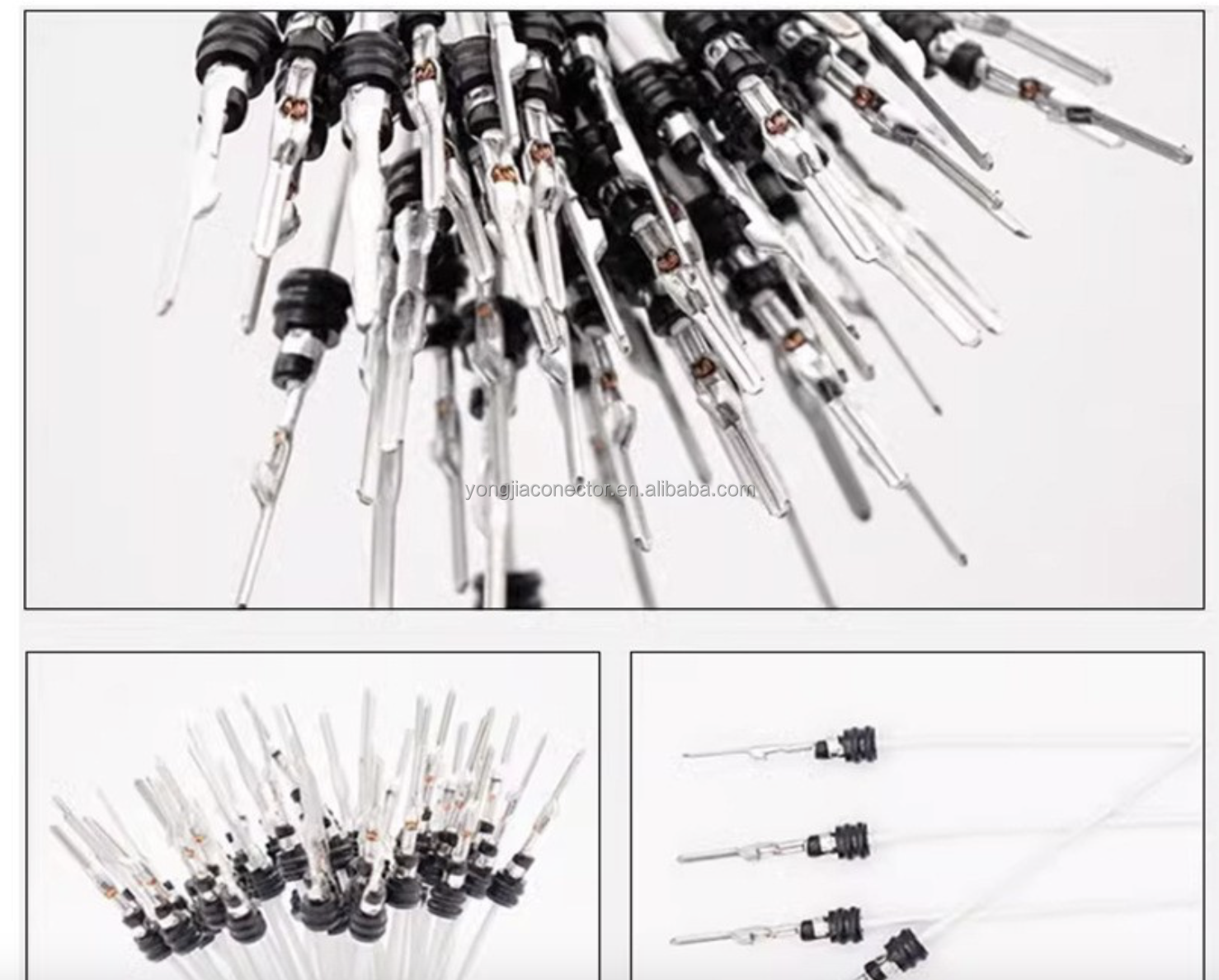

Finished samples: