What if the milling cutter is not sized enough?

resolvent:

1. Excessive cutting Reduce the depth and width during the cutting

2. Lack of accuracy for the machine or fixtures

Repair the machine and the fixtures

3. Lack of rigidity in machines or fixtures

Change the machine fixtures or the cutting settings

4. Too few blades

Use multi-blade milling machines

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DINGLI

-

Model Number:

-

OK

-

Product Name:

-

Carbide end mills

-

Suitable for:

-

Aluminum Processing

-

HRC:

-

45/55/60/65 HRC

-

End Mill Type:

-

Corner Radius Milling Cutter

-

Flute:

-

2/3/4Flutes

-

Machine Type:

-

CNC Miling Machine

-

Keyword:

-

single flute milling cutter

-

Color:

-

Customized Color

-

Type:

-

Miling Cutter,carbide endmill

Quick Details

-

Material:

-

Carbide

-

Coating:

-

AlTiN, TiAIN, TiCN, Tin

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

DINGLI

-

Model Number:

-

OK

-

Product Name:

-

Carbide end mills

-

Suitable for:

-

Aluminum Processing

-

HRC:

-

45/55/60/65 HRC

-

End Mill Type:

-

Corner Radius Milling Cutter

-

Flute:

-

2/3/4Flutes

-

Machine Type:

-

CNC Miling Machine

-

Keyword:

-

single flute milling cutter

-

Color:

-

Customized Color

-

Type:

-

Miling Cutter,carbide endmill

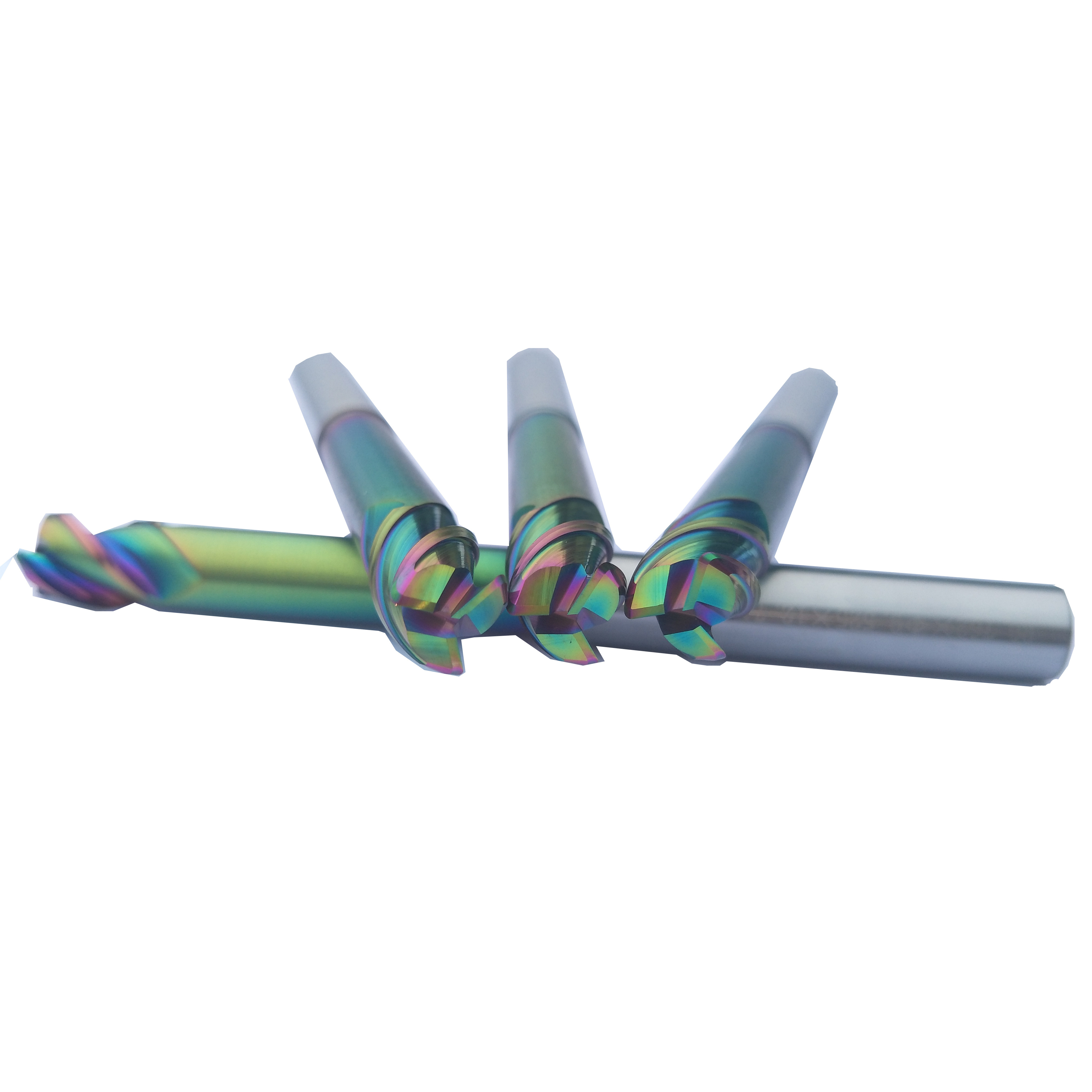

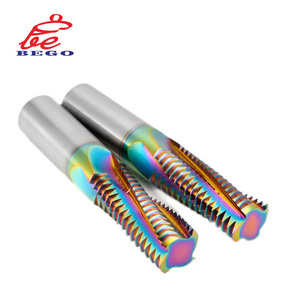

Related Products

Product Overview

The main use of the milling machines

Generally, it is divided into:

1, Flat head milling knife, rough milling, remove a large number of blank, small area horizontal plane or contour precision milling.

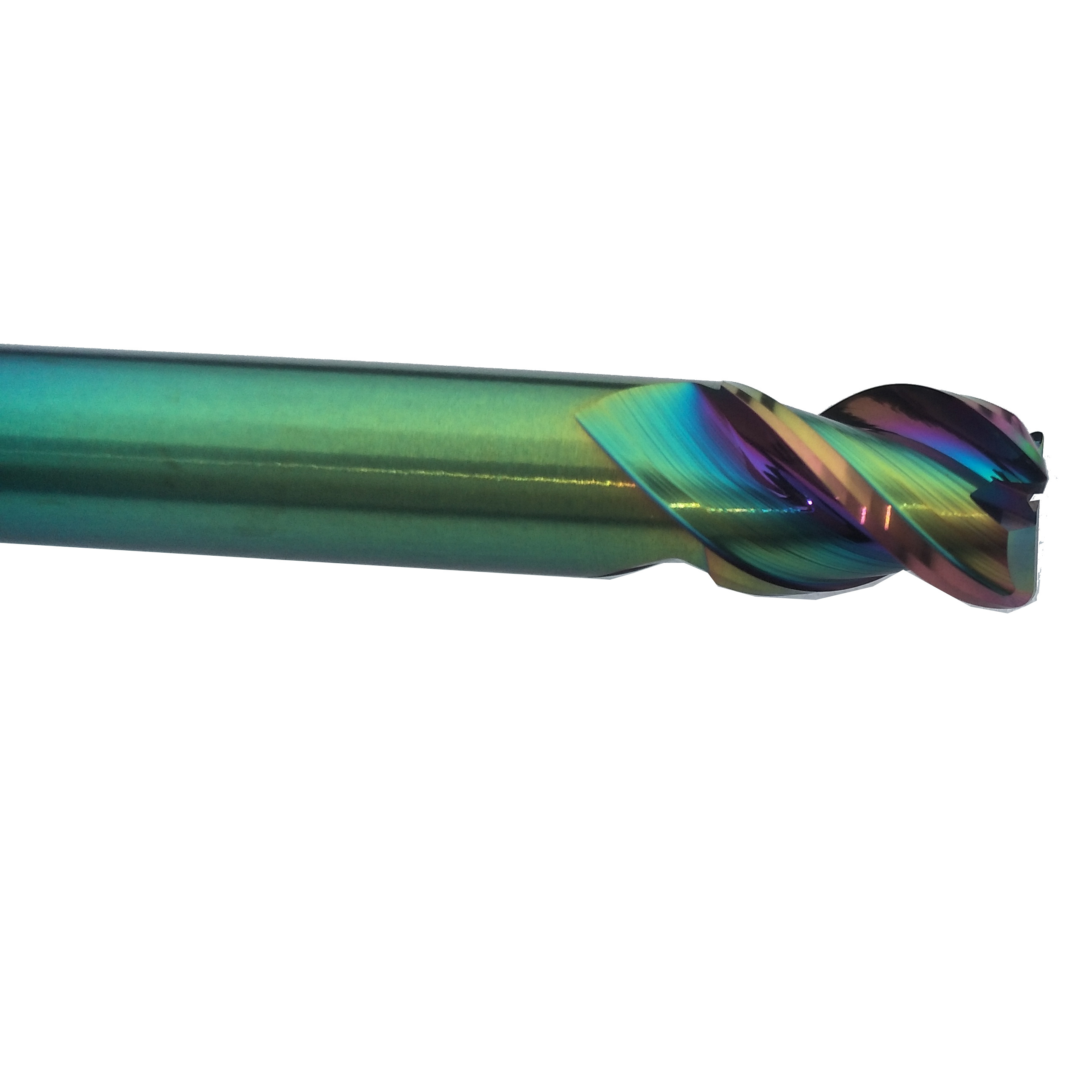

2. Ball milling tool, curved semi-precision milling and fine milling; small ball milling tool can fine small chamfer of steep surface / straight wall and irregular contour surface.

3, Flat head milling knife with chamfer, can be done rough milling to remove a large number of rough work, but also fine milling fine flat surface (relative to the steep surface) small chamfer.

4. Forolding milling knife, including chamfer knife, T-shaped milling knife or drum knife, tooth knife, inner R knife.

5, The chamfer knife, the chamfer knife shape and the chamfer shape is the same, divided into milling round chamfer and inclined chamfer milling knife.

6, T-type knife, milling T-type groove.

Dental knife, milling out a variety of teeth, such as gear.

8, Crude leather knife, for aluminum and copper alloy cutting design of rough milling cutter, can be quickly processed.

FEATURES AT A GLANCE

What if the milling cutter is not sized enough?

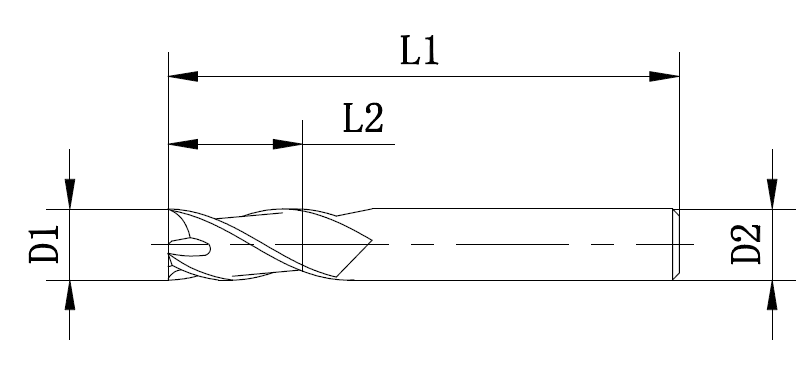

Right elevation

Left elevation

Front elevation

PRODUCT SPECIFICATIONS

Hot Searches