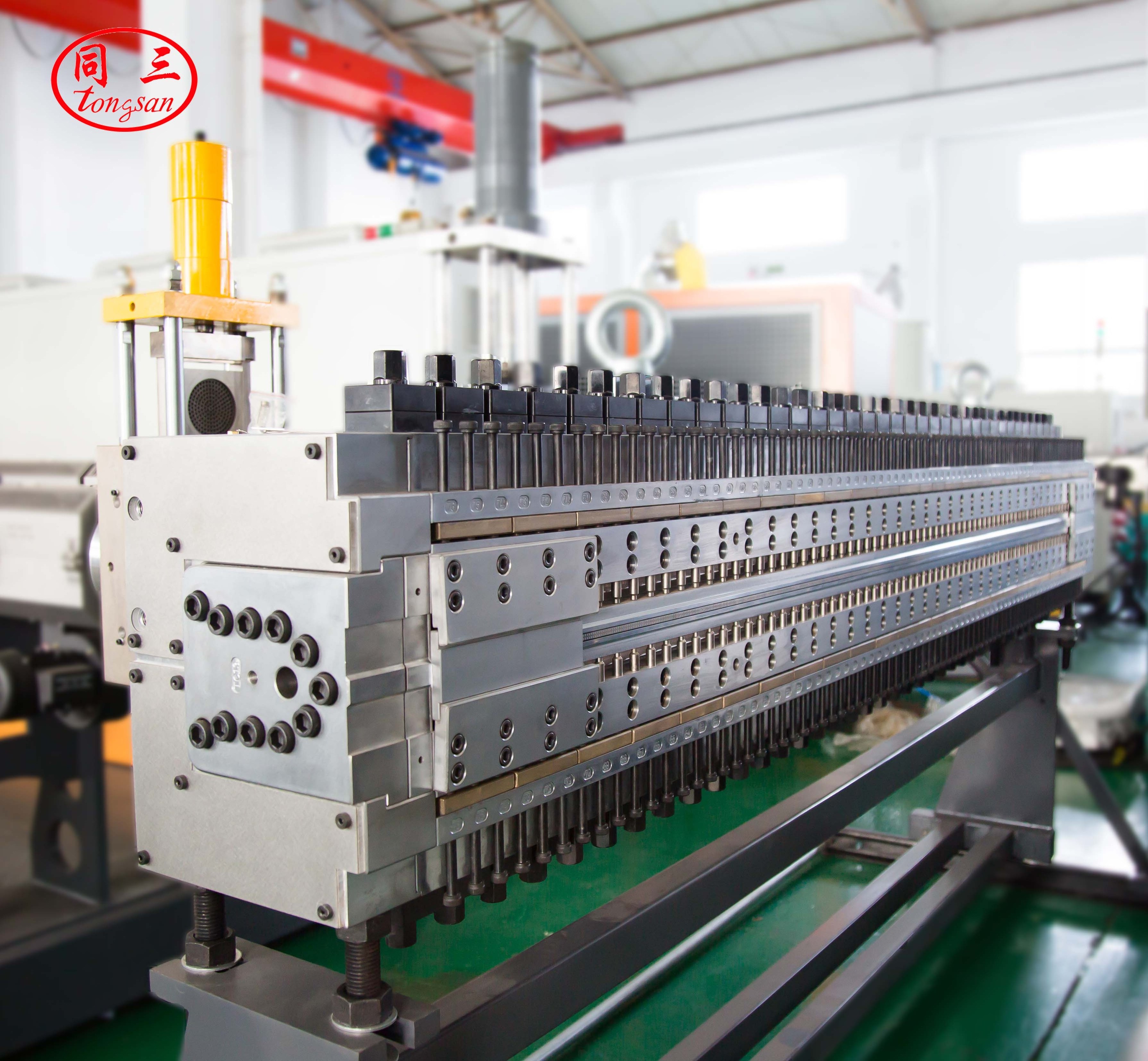

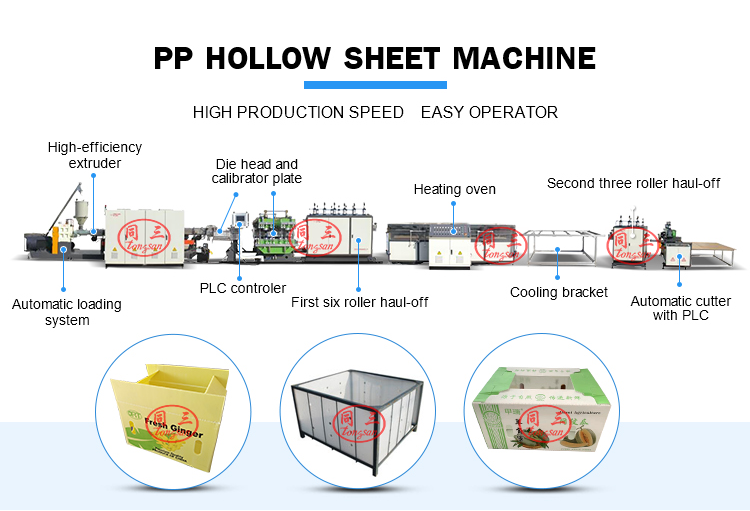

Fluted PP corrugated board/PP corrugated hollow board making machine

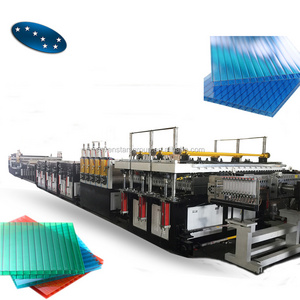

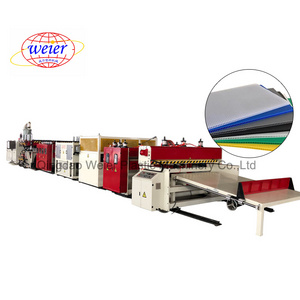

realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging box. PE/PP hollow corrugated sheet is an ideal substitute for carton box in making packaging box. It is characterized by light weight, high intensity, damp proof, and anti-corrosion.

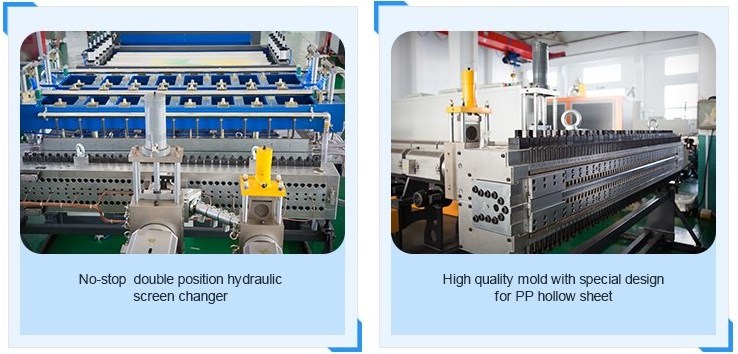

We have all series high quality PP hollow corrugated sheet machine ,the width of the products is 1220-2800 mm, and the thickness is 1 mm-12 mm.The extrusion line can reach 2-10 m/min, the high capacity at 200-600 kg/h.We provide high out production line with professional technology support,and auxiliary machine for package box making machines.

We have customer in India, Mexico, Ecuador, Uzbekistan, Vietnam,etc.We have won praise from customers for the quality of our machines and service.Tongsan continues to innovate with the industry's leading level.Looking forward to working with you for a win-win cooperation.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONGSAN&HEGU

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

30*3*2M

-

Power (kW):

-

150

-

Weight:

-

3000 KG

-

Sheet width:

-

1200-3000mm

-

Sheet thickness:

-

2-12mm

-

Motor brand:

-

Siemens

-

Inverter:

-

ABB

-

Temperature controller:

-

Omron

-

Material:

-

PP+Filler

-

Plastic hollow sheet making machine:

-

plastic pp corrugated hollow sheet making production machine

-

Product:

-

plastic pp corrugated hollow sheet board plate profile

-

Application Field:

-

packiging box,partition layer pad,display signs

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

36:1

-

Screw Speed (rpm):

-

260 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONGSAN&HEGU

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

30*3*2M

-

Power (kW):

-

150

-

Weight:

-

3000 KG

-

Sheet width:

-

1200-3000mm

-

Sheet thickness:

-

2-12mm

-

Motor brand:

-

Siemens

-

Inverter:

-

ABB

-

Temperature controller:

-

Omron

-

Material:

-

PP+Filler

-

Plastic hollow sheet making machine:

-

plastic pp corrugated hollow sheet making production machine

-

Product:

-

plastic pp corrugated hollow sheet board plate profile

-

Application Field:

-

packiging box,partition layer pad,display signs

Product Description

Machine manufacturer since 1997

Plastic flute board making machine

Fluted Polypropylene Board Making Production Machine

PP corex corrugated board making production machine

Specification

|

Model

|

Sheet width

|

Sheet thickness

|

Extruder Model

|

Motor Power

|

|

TSGZB-1400

|

1250mm

|

2-6,8-12mm

|

100/36

|

75kw

|

|

TSGZB-1860

|

1700mm

|

2-6,8-12mm

|

120/36

|

90kw

|

|

TSGZB-2300

|

2150mm

|

2-6,8-12mm

|

120/36

|

110kw

|

|

TSGZB-2600

|

2450mm

|

2-6,8-12mm

|

120/36

|

110kw

|

|

TSGZB-3000

|

2800mm

|

2-6,8-12mm

|

150/36

|

132kw

|

|

TSGZB-2600(F)

|

2450mm

|

2-6,8-12mm

|

120/36&80/36

|

110+37kw

|

PP Corrugated Plastic Sheet is a twin wall profile extrusion, connected by a series of vertical ribs,

also called Coreflute, Corflute, Correx Sheet,Corex Sheet, PP coroplast Sheet.

The PP corrugated sheet can be widely used in packaging, advertising, construction, agriculture, hardware, layer pad industry and others.

PP Hollow Profile Sheet is a double wall profile extrusion, joint by series of vertical ribs, providing semi rigid sheets with high impact properties and excellent strength to weight ratio. Polypropylene Hollow Profile Sheet is a versatile product with worldwide applications due to properties of tough Polypropylene.

Uses of PP Corflute sheets are endless. These boxes are made from a material, which is widely used in packaging of vegetables, fruits, fish & plant, Glass and Pharmaceutical Packaging, Composite Boxes for Automotive Components as well as Conductive & Anti Static grades for Packaging of sensitive Electronics components. These sheets are now popular in Collapsible Bulk Bins Market.

The advantage of PP hollow sheet

1. Good mechanical properties

The special structure of the plastic hollow board makes it have excellent mechanical properties such as good toughness, impact resistance, high compressive strength, cushioning and shockproof, high stiffness, and good bending performance.

2. Lightweight and economical material

The plastic hollow board has excellent mechanical properties, and the same effect should be achieved year-on-year. The use of plastic hollow board has less consumables, low cost and light weight.

3. Heat insulation and sound insulation

Due to the hollow structure of the plastic hollow board, its heat and sound transmission effect is significantly lower than

that of the solid board, and it has good heat insulation and sound insulation effects.

4. Anti-static, conductive, flame retardant

Modification, mixing, surface spraying and other methods can make the plastic hollow board have anti-static, conductive, or flame-retardant properties.

5. Stable chemical performance

Plastic hollow board can be waterproof, moisture-proof, anti-corrosion, insect-proof, and fumigation-free. Compared with

cardboard and wood board, it has obvious advantages.

6. The surface is smooth and beautiful, with complete colors

Due to the special molding process of the plastic hollow board, any color can be achieved through the toning of the

masterbatch, and the surface is smooth and easy to print.

7. Obvious environmental protection effect

The plastic hollow board has the characteristics of non-toxic, non-polluting, etc., is simple to dispose of, and will not

pollute the environment. It can also be reused to make other plastic products.

Wide-range in application

PP Plastic Hollow Corrugated sheet/Plate in Fruit,Vegetable and Food Packaging

PP Plastic Hollow Corrugated sheet/Plate in Industrial Packagin

PP Plastic Hollow Corrugated sheet/Plate in Packaging of Glass Bottles

PP Plastic Hollow Corrugated sheet/Plate in Advertising Decoration and Advertising Printing

PP Plastic Hollow Corrugated sheet/Plate in Refrigerator and Washing Machine

PP Plastic Hollow Corrugated sheet/Plate in Advertising Decoration and Advertising Printing

PP Plastic Hollow Corrugated sheet/Plate in Refrigerator and Washing Machine

Our serivce

1,We have all series plastic hollow corrugated sheet making machine in production,warmly welcome to visit our factory for machine running.The machine running is the best prove of the machines' quality ,the good quality machine is the granulating for the high effective production.

2,We can testing the machine according customer's formula.One is the customer can inspect the quality of our machine,another is the customer can check the quality of the products,so it is easy to calculate the cost of the sheet and the production capacity of our machines.So it's easy to calculate the investment pay back and increase the feasibility of the project.

3,We are professional for the auxiliary machine for sheet raw material making and plastic boxes making.We can provide the plastic filler masterbatch granulating making machine,the wast sheet crusher,the raw material mixing machine,the die cutting machine,the corona treatment machine,the sheet printing machine,the welding / bookbind machine .

4,Our engineer oversee installation and debugging ,our engineer with rich experience and will teach customer's worker about the operating one by one.And we provide long life time technical support.

2,We can testing the machine according customer's formula.One is the customer can inspect the quality of our machine,another is the customer can check the quality of the products,so it is easy to calculate the cost of the sheet and the production capacity of our machines.So it's easy to calculate the investment pay back and increase the feasibility of the project.

3,We are professional for the auxiliary machine for sheet raw material making and plastic boxes making.We can provide the plastic filler masterbatch granulating making machine,the wast sheet crusher,the raw material mixing machine,the die cutting machine,the corona treatment machine,the sheet printing machine,the welding / bookbind machine .

4,Our engineer oversee installation and debugging ,our engineer with rich experience and will teach customer's worker about the operating one by one.And we provide long life time technical support.

If you are interested in our Plastic Corrugated Hollow Sheet Machine,please contact me at any time.

Hot Searches