- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

2 years

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BADA

-

Model Number:

-

BDDR 2001

-

Type:

-

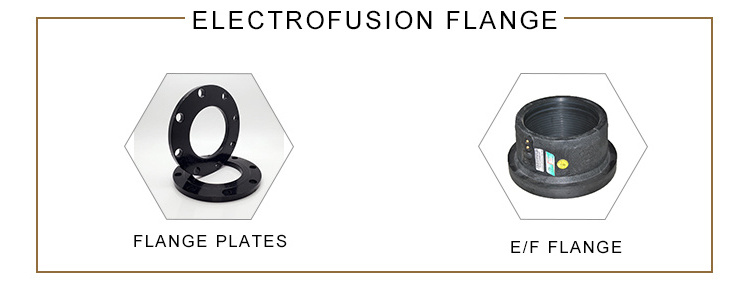

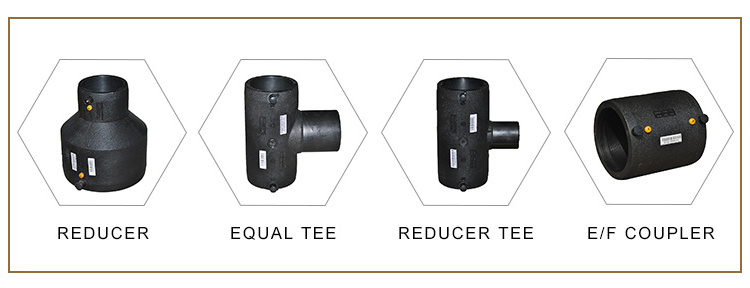

electro fusion reducer/coupling/elbow/Tee

-

Application:

-

water supply, gas supply, repairing

-

Material::

-

PE80 or PE100

-

Color:

-

Black electrofusion fittings

-

Packing:

-

Carton

-

longevity:

-

more than 50 years

-

Feature:

-

Thicker wall

-

Keyword:

-

hdpe electrofusion fitting

Quick Details

-

Technics:

-

Casting

-

Shape:

-

Equal

-

Head Code:

-

Square

-

Warranty:

-

2 years

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BADA

-

Model Number:

-

BDDR 2001

-

Type:

-

electro fusion reducer/coupling/elbow/Tee

-

Application:

-

water supply, gas supply, repairing

-

Material::

-

PE80 or PE100

-

Color:

-

Black electrofusion fittings

-

Packing:

-

Carton

-

longevity:

-

more than 50 years

-

Feature:

-

Thicker wall

-

Keyword:

-

hdpe electrofusion fitting

Products Description

Details Images

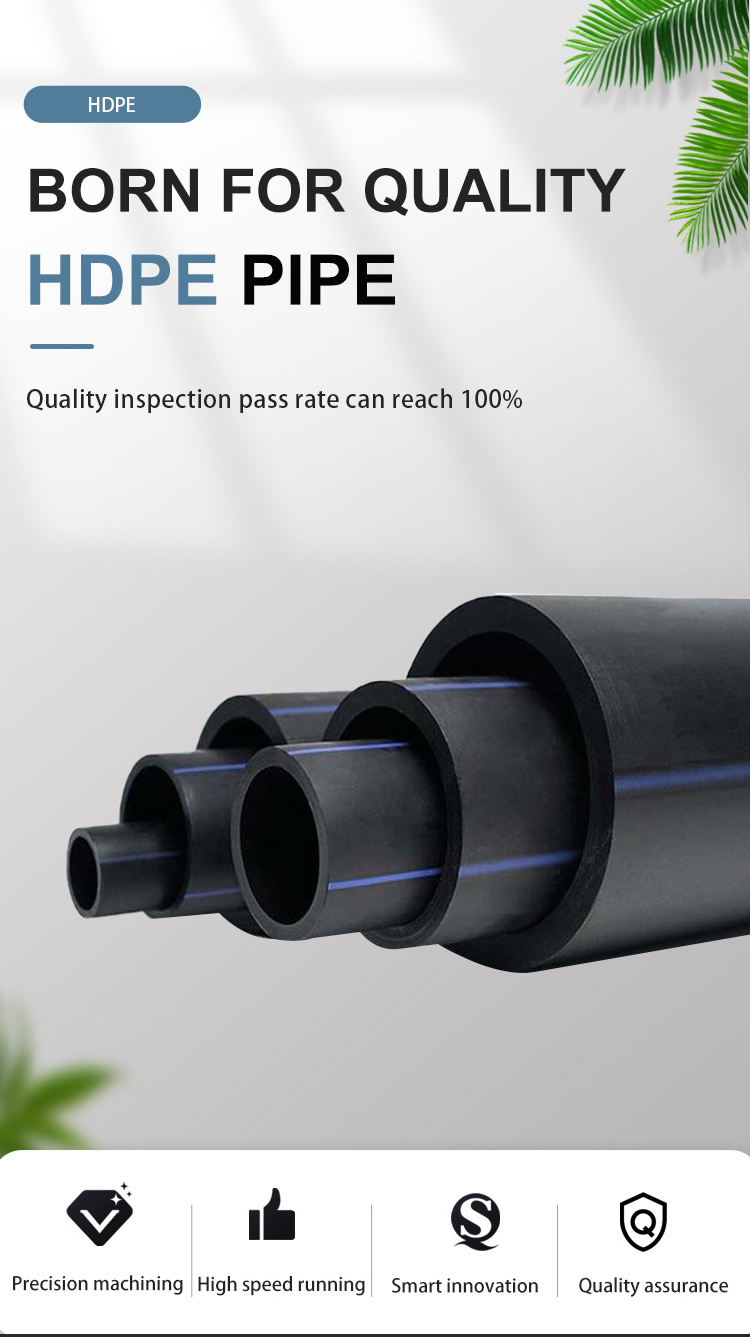

PE100 poly pipe hdpe electrofusion fitting elbow tee joints for pe pipes clamps electro butt fusion fitting of pipe

1. Unique Design: Choose the maximum high pressure design, guarantee system security.

Accurate marking line of insertion depth and angle, saving time and construction cost

2. Superior Materials: We choose imported specialized resin suitable for pipe to produce PE fittings.

3. Lean Production: With sophisticated injection mold, automatic production, the dimension of pipe fitting is precise.

4. TCT : Guarantee the stability of product size.

5. Long Life: More than 50 years under normal conditions.

Accurate marking line of insertion depth and angle, saving time and construction cost

2. Superior Materials: We choose imported specialized resin suitable for pipe to produce PE fittings.

3. Lean Production: With sophisticated injection mold, automatic production, the dimension of pipe fitting is precise.

4. TCT : Guarantee the stability of product size.

5. Long Life: More than 50 years under normal conditions.

|

Basic performance of raw materials for pipe fittings

|

|

|

|

|

||||

|

Paramenter

|

|

Units

|

Requirement

|

Test Value

|

||||

|

Density

|

|

(kg/m3)

|

≥930

|

23°C

|

||||

|

Melt flow rate

|

|

g/10min

|

0.2-1.4

|

190°C,5kg

|

||||

|

Thermal slaility(OIT)

|

|

min

|

>20

|

200°C

|

||||

|

Volatilematter content

|

|

mg/kg

|

≤ 350

|

|

||||

|

Moisture content

|

|

mg/kg

|

≤ 300

|

ASTM D 4019:1994a

|

||||

|

Carbon black content

|

|

%

|

2.0-2.5

|

|

||||

|

Carbon black dispersion

|

|

grade

|

≤ 3

|

|

||||

|

Gas proof components

|

|

h

|

≥20

|

80°C,2MPa Hoop stress

|

||||

|

En>5mm Resitance to slow crack growth

|

|

h

|

165

|

80°C,0.8MPa Test Presssure 80°C,0.92MPa Test Presssure

|

||||

Using the process

Hot Searches