- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HY

-

Product Name:

-

2022 Hot Selling New Prestressed Concrete Pile Steel Mold

-

Certification:

-

ISO9001:2008

-

Diameter:

-

300-1500mm

-

Length:

-

6-15m

-

Type:

-

round and square

-

Keyword:

-

concrete pile mold

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HY

-

Model Number:

-

HY

-

Product Name:

-

2022 Hot Selling New Prestressed Concrete Pile Steel Mold

-

Certification:

-

ISO9001:2008

-

Diameter:

-

300-1500mm

-

Length:

-

6-15m

-

Type:

-

round and square

-

Keyword:

-

concrete pile mold

|

No.

|

Inner Diameter/mm

|

Distance of wheels/mm

|

Diameter of Wheels/mm

|

Length/m

|

|

1

|

∅300

|

2000

|

∅600

|

7~11

|

|

2

|

∅400

|

2000

|

∅640

|

7~12

|

|

3

|

∅500

|

2000

|

∅740

|

7~15

|

|

4

|

∅600

|

2000

|

∅840

|

7~15

|

|

5

|

∅700

|

2000

|

∅1000

|

7~39

|

|

6

|

∅800

|

2000

|

∅1100

|

7~60

|

|

7

|

∅1000

|

2000

|

∅1300

|

7~60

|

|

8

|

∅1200

|

2000

|

∅1500

|

7~60

|

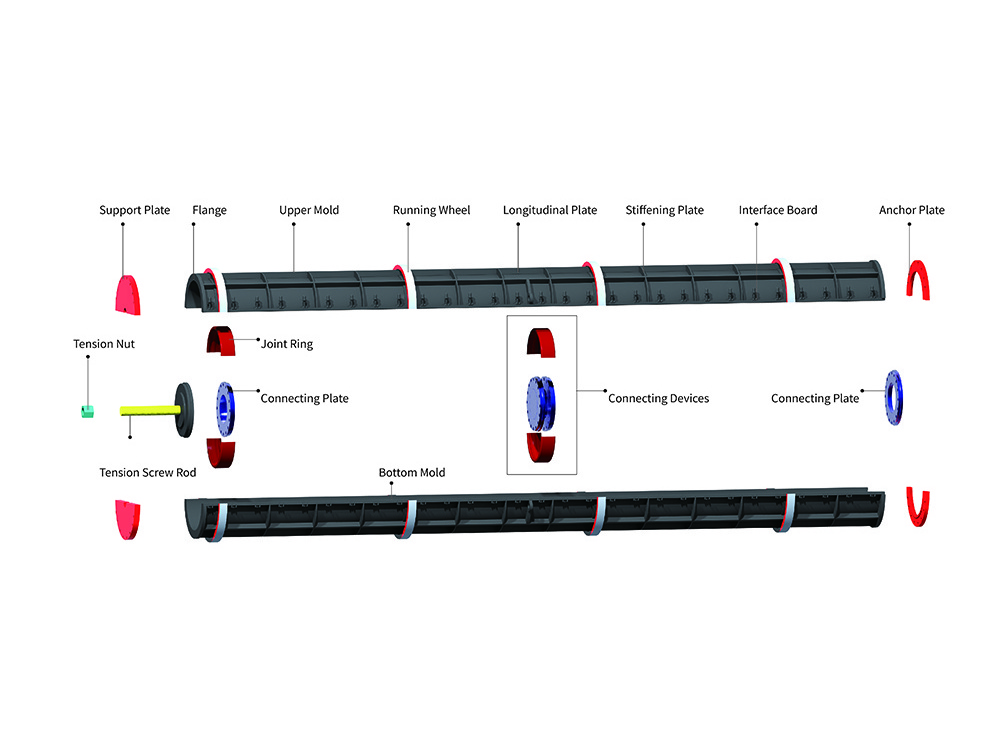

Our concrete spun pile mould has the following characters:

1. The cylinder of pile moulds is made to order according to different piles, the longest cylinder is 6m with less welding seam

and reduce influence of welding distortion and error of manual joining, the material is Q235B or Q345B. 2. The material of mould

wheels is hammer or cast steel, wheels are made by automatic Panasonic welding robot, high welding strength and less welding

stress. 3. Our moulds adopt intermittent welding technology, welding method is CO2 gas shield welding, we also use Panasonic

welding machine and mixture gas to weld moulds, a solid solder joint appearance, there is no brittle fracture caused by manual

welding, oxidation, solder false. 4. Our company has introduced 18m heavy duty lathe, the mould below 12m adopts whole lathe

machining to improve concentricity of moulds. 5. Our customers can choose different types of steel plates and flanges. 6. The

processing equipment of join plate is from the previous planer processing technology to the milling machine processing technology,

improved production efficiency, saving labor costs.

and reduce influence of welding distortion and error of manual joining, the material is Q235B or Q345B. 2. The material of mould

wheels is hammer or cast steel, wheels are made by automatic Panasonic welding robot, high welding strength and less welding

stress. 3. Our moulds adopt intermittent welding technology, welding method is CO2 gas shield welding, we also use Panasonic

welding machine and mixture gas to weld moulds, a solid solder joint appearance, there is no brittle fracture caused by manual

welding, oxidation, solder false. 4. Our company has introduced 18m heavy duty lathe, the mould below 12m adopts whole lathe

machining to improve concentricity of moulds. 5. Our customers can choose different types of steel plates and flanges. 6. The

processing equipment of join plate is from the previous planer processing technology to the milling machine processing technology,

improved production efficiency, saving labor costs.

Q:Do you have set up an independent factory?

A:We have our own factory. Has the specialized cement machinery product equipment factory, also has the large-scale cement drain pipe production factory.

Q:What can you do for us?

A:1. Before sales can be targeted to give some constructive Suggestions.

2.Make a specific plan for your needs.

3. After sales reference specific products, different products have different services. Refer to the specific product description.

Q: Can you do the basic design for us?

A: Yes, we have a professional team with rich experience in basic design of cement pipe making equipment with CAD software. You just need to tell us your ideas and requirements, and we will provide you with the most perfect design.

Q:Can your engineers train our workers in our factories?

A:Yes, we have a very large engineering installation team that can train and instruct your workers to operate the installation equipment.

Q:If we provide the parameter requirements, can we make it to order?

A:We provide customized services as long as you provide the appropriate drawings and product requirements.

Q:How long is your lead time?

A:Our delivery time varies according to the quantity of the order, usually around 30 days.

Hot Searches