- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/50HZ

-

Power:

-

59kw

-

Weight:

-

4500 KG

-

Dimension(L*W*H):

-

28400*4900*2300mm

-

Year:

-

2023

-

Product name:

-

kurkure chips cheetos nik naks snack making extruder

-

Application:

-

Food Processing Machine

-

Name:

-

Snack Food Extruder

-

Usage:

-

Food Industry Equipment

-

Function:

-

Multifunctional

-

Type:

-

Fully Automatic

-

Keywords:

-

Easy Operate High Productivity

-

After-sales Service Provided:

-

Online Support

-

Material:

-

Food Grade Stainless Steel

-

Raw material:

-

Corn Flour Wheat Flour

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DAYI

-

Voltage:

-

220V/50HZ

-

Power:

-

59kw

-

Weight:

-

4500 KG

-

Dimension(L*W*H):

-

28400*4900*2300mm

-

Year:

-

2023

-

Product name:

-

kurkure chips cheetos nik naks snack making extruder

-

Application:

-

Food Processing Machine

-

Name:

-

Snack Food Extruder

-

Usage:

-

Food Industry Equipment

-

Function:

-

Multifunctional

-

Type:

-

Fully Automatic

-

Keywords:

-

Easy Operate High Productivity

-

After-sales Service Provided:

-

Online Support

-

Material:

-

Food Grade Stainless Steel

-

Raw material:

-

Corn Flour Wheat Flour

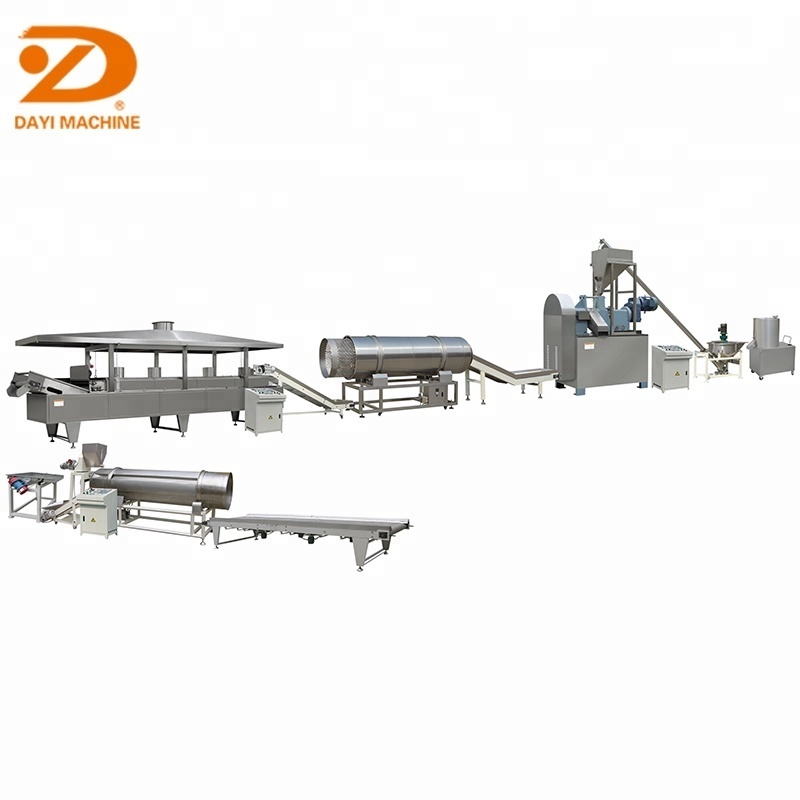

Corn kurkure cheetos making machine production line

Cheetos kurkure niknaks process line c an be manufactured special snack with extreme crispy taste. The main raw material is corn grits which is mixed with water evenly by the flour mixer, squeezed and twisted by the extruder to form the iregular curls shape, and then cut into different length, at last fried or baked and flavored. Such snacks with rich taste are always the customer's favor.

Production Flow

:

Flour Mixer → Cheetos Extruder → Conveyor → Rotary Sifter → Elevator → Fryer → Vibrating De-Oiler → Flavoring Line → Cooling Conveyor

Main Features

|

Name

|

Cheetos Extruder

|

|

Diameter of screw

|

φ74mm

|

|

Main driving power

|

5.5kw

|

|

Extruding driving power

|

22kw

|

|

Capacity

|

100~150kg/h

|

|

Dimension

|

2100x785x2280mm

|

|

Name

|

LF-Rotayr Separate Sifter

|

|

Driving power

|

0.37kw

|

|

Capacity

|

150kg/h

|

|

Size of roller

|

Φ636×2865mm

|

|

Dimension

|

2865x780x2650mm

|

|

Name

|

LXZ4000 Continuous Frying Line

|

|

Conveying power

|

1.5kw

|

|

Electric heating power

|

70kw

|

|

Frying temperature

|

0~250℃ adjustable

|

|

Capacity

|

260~500kg/h

|

|

Dimension

|

4400×2050×2300mm

|

|

Name

|

PF-PG Oil Spray Flavoring Line

|

|

PF Driving power

|

0.75KW

|

|

Capacity

|

0~250kg/h

|

|

Dimension

|

1300×450×1600mm

|

|

PG Driving power

|

0.37KW

|

|

Drum size

|

636×2700mm

|

|

Dimension

|

2700×750×1500mm

|