- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380/450V

-

Power:

-

140kw

-

Weight:

-

4.5Ton

-

Dimension(L*W*H):

-

42600*3200*3100

-

Warranty:

-

1 Year

-

Certification:

-

CE,ISO

-

Capacity:

-

150-600kg/h

-

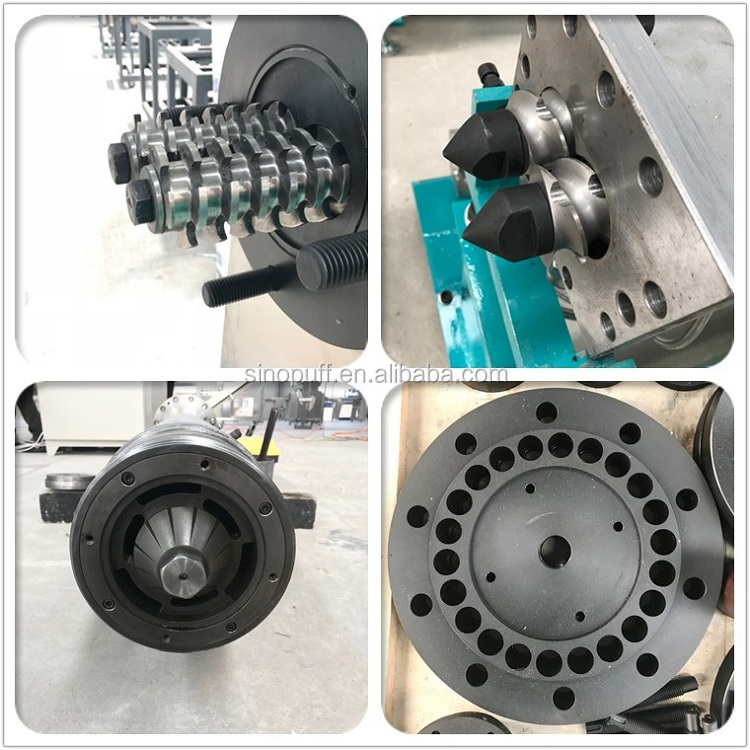

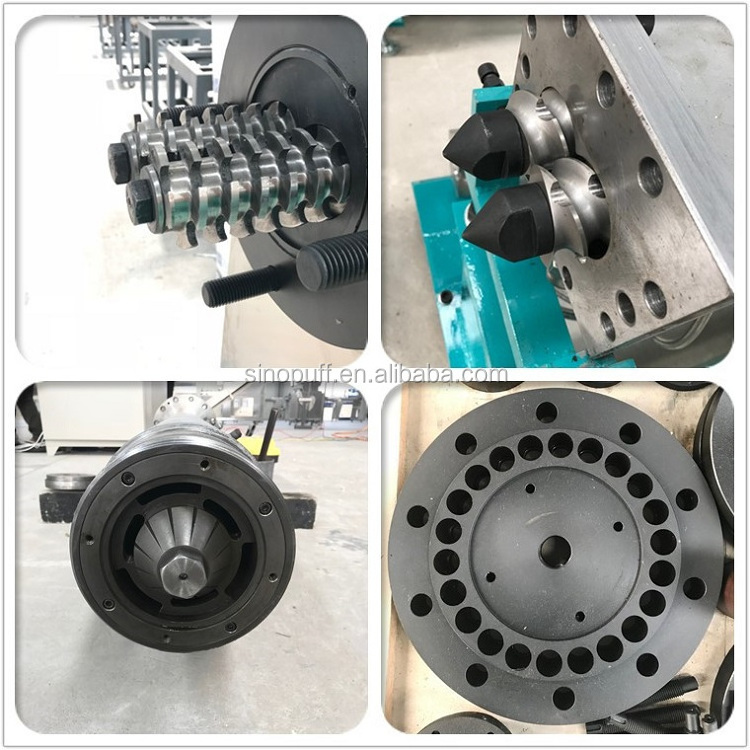

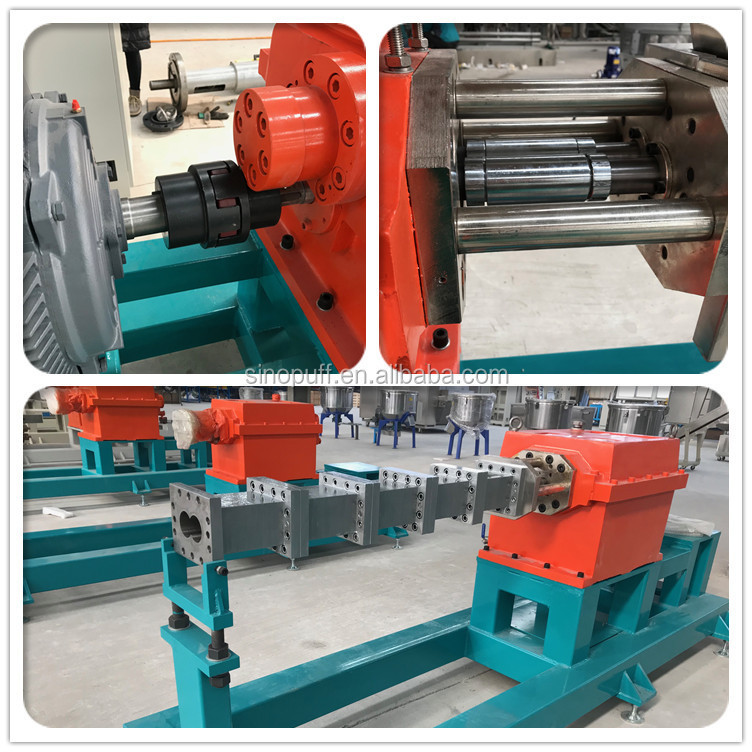

Screw Diameters:

-

52/65/70/75/85/90mm

-

Power Source:

-

Eletricity/Gas/LPG/Diesel

-

Mould:

-

Standard/Customized

-

Motors:

-

Sismens

-

Invertors:

-

Delta/ABB

-

Bearing:

-

Imported(Japan NSK)

-

Electric Device:

-

ABB

-

Material:

-

Food Grade Stainless Steel

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sinopuff

-

Model Number:

-

SP70-II

-

Voltage:

-

220/380/450V

-

Power:

-

140kw

-

Weight:

-

4.5Ton

-

Dimension(L*W*H):

-

42600*3200*3100

-

Warranty:

-

1 Year

-

Certification:

-

CE,ISO

-

Capacity:

-

150-600kg/h

-

Screw Diameters:

-

52/65/70/75/85/90mm

-

Power Source:

-

Eletricity/Gas/LPG/Diesel

-

Mould:

-

Standard/Customized

-

Motors:

-

Sismens

-

Invertors:

-

Delta/ABB

-

Bearing:

-

Imported(Japan NSK)

-

Electric Device:

-

ABB

-

Material:

-

Food Grade Stainless Steel

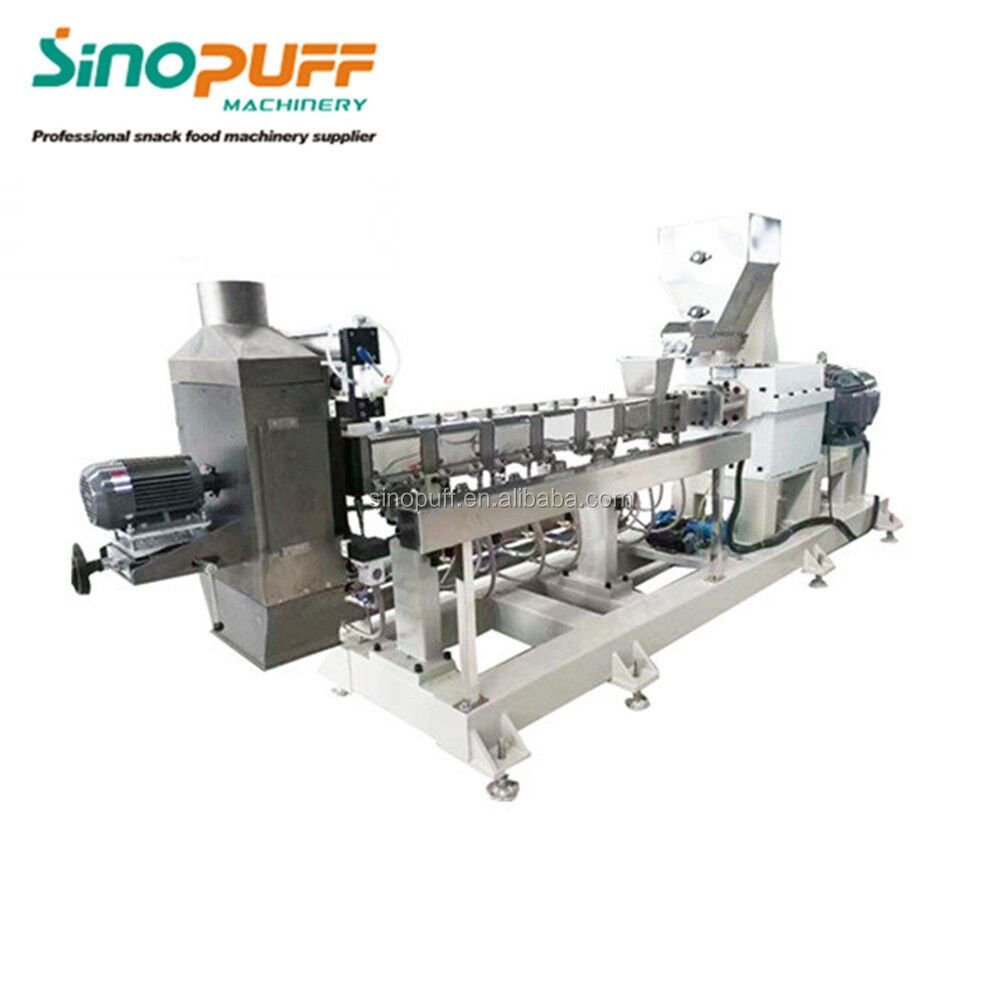

Introduction:

China Manufacturer "Sinopuff" Pani Puri Making Machine adopts wheat flour, corn starch, potato starch, potato flour as the raw material; Through screw extruding, it shapes kinds of 2d/3d pellet, by drying, frying(Or Hot Air Popper) and seasoning, it will be puffed twice to fourth times with crispy taste;

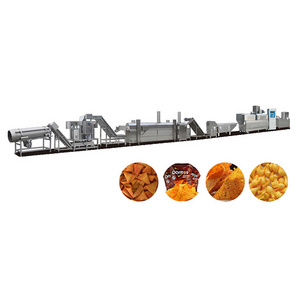

Classic Process:

Raw Material Mixing → Cooking and Extruding → Drying →Frying → Seasoning → Packaging

Basic Formula :

Wheat flour, corn starch, potato starch, potato flour and Food Additive

Product Reference:

Machine Parameters:

|

Model |

Installed Power |

Power Consumption |

Capacity/Output |

Dimension |

|

SP65-II Twin Screw Extruder |

42.9kw |

30kw |

100-180kg/h |

3070x960x2050mm |

|

SP65-III Twin Screw Extruder |

31.3kw |

22kw |

100-150kg/h |

2600x960x2000mm |

|

SP70-III Twin Screw Extruder |

64.45kw |

40kw |

200-250kg/h |

3320x960x2100mm |

|

SP75-III Twin Screw Extruder |

79.05kw |

50kw |

250-350kg/h |

4650x1100x2200mm |

|

SP85-III Twin Screw Extruder |

97kw |

72kw |

350-500kg/h |

4800x1100x2300mm |

|

SP52-II Twin Screw Extruder |

54.3kw |

40kw |

100-150kg/h |

4500x900x1820mm |

|

SP75-II Twin Screw Extruder |

89.7kw |

67.3kw |

200-350kg/h |

5200x1100x2200mm |

|

SP90-I Twin Screw Extruder |

161.3kw |

121kw |

350-800kg/h |

5800x1200x2500mm |

Sinopuff Machinery

Sinopuff Machinery is the professional manufacturer of extrusion food machinery and related food machinery from China, such as Twin Screw Extruder, Single-screw Extruder, Dryer, Fryer, Popcorn machine and related auxiliary machineries, such as package machinery,metal & weight detector.

- Before Purchasing: We will provide professional technical project and sales consultation service to solve the customers' question and worried;

- During Production: Timely updates the machine status for customer to ensure delivery time, and quality

- After Production: Machine testing video and photos will be provided for inspection, if the customer can't come;

- Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the seller;

- Installation & Training: Providing professional and expert technical engineers to supply the training and installation service.

-

After Sales Service;

1 Web based service(solve your problem through email/phone call/video communication).

2 Engineers abroad available ,arrange engineers help to install and test the machine, train your employees about the operation and maintenance.

3 Cooperate with 3rd party organization or engineers from your country to offer door to door service.

1 Where is your factory?

Jinan city, Shandong Province, China

2 What is your machine warranty?

1 year, main parts warranty time will be 2 or 3 years.

3 Do you supply spare parts?

Yes, we supply spare parts with reasonable price;

4 What can you provide for after sale service?

We can send engineers to your factory for installation and training if customers‘ required.

5 If we show you our layout of factory, can you help to design the whole process line?

Yes, our experienced engineers and technical employee can help you to arrange the layout and installation of whole process line based on your real situation;

6 How can we contatc you if we meet problems during production?

Phone/email/wechat/whatsapp/Skype are all available.

7 If we have samples of new products, can you help to analysis and design the machine?

Yes, Our technical department can help to analysis, design and test the new products you offered.