- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2KW

-

Dimension(L*W*H):

-

1100*500*1750mm

-

Weight:

-

100KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Material:

-

borosilicate glass/stainless steel 316

-

Heat exchange Surface:

-

0.058m2

-

Inner Condensing Surface:

-

0.065m2

-

Temperature:

-

max:200℃

-

Vacuity:

-

min:0.001mbar

-

Film system:

-

Self-Clean Roll Filming System

-

Rotation Speed:

-

80-390rpm

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Dea

-

Voltage:

-

220v

-

Power:

-

2KW

-

Dimension(L*W*H):

-

1100*500*1750mm

-

Weight:

-

100KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Material:

-

borosilicate glass/stainless steel 316

-

Heat exchange Surface:

-

0.058m2

-

Inner Condensing Surface:

-

0.065m2

-

Temperature:

-

max:200℃

-

Vacuity:

-

min:0.001mbar

-

Film system:

-

Self-Clean Roll Filming System

-

Rotation Speed:

-

80-390rpm

-

Certification:

-

ISO

|

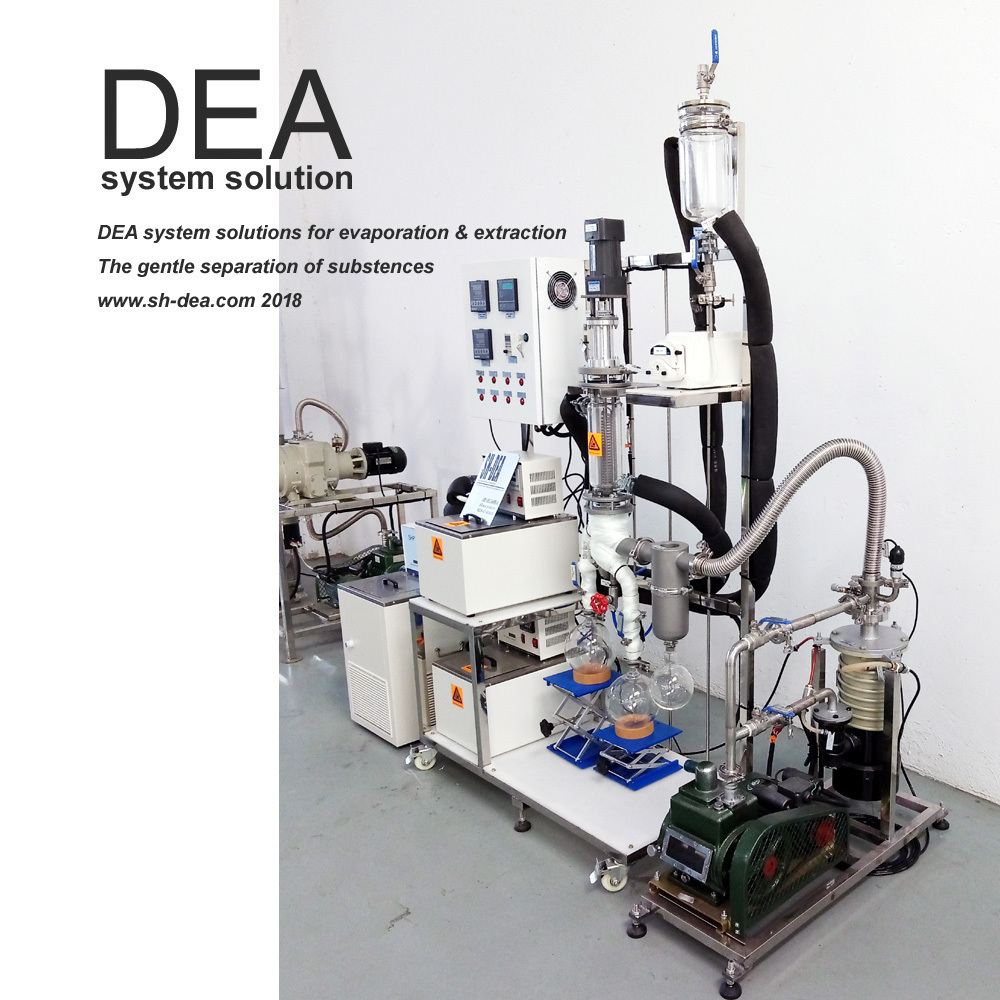

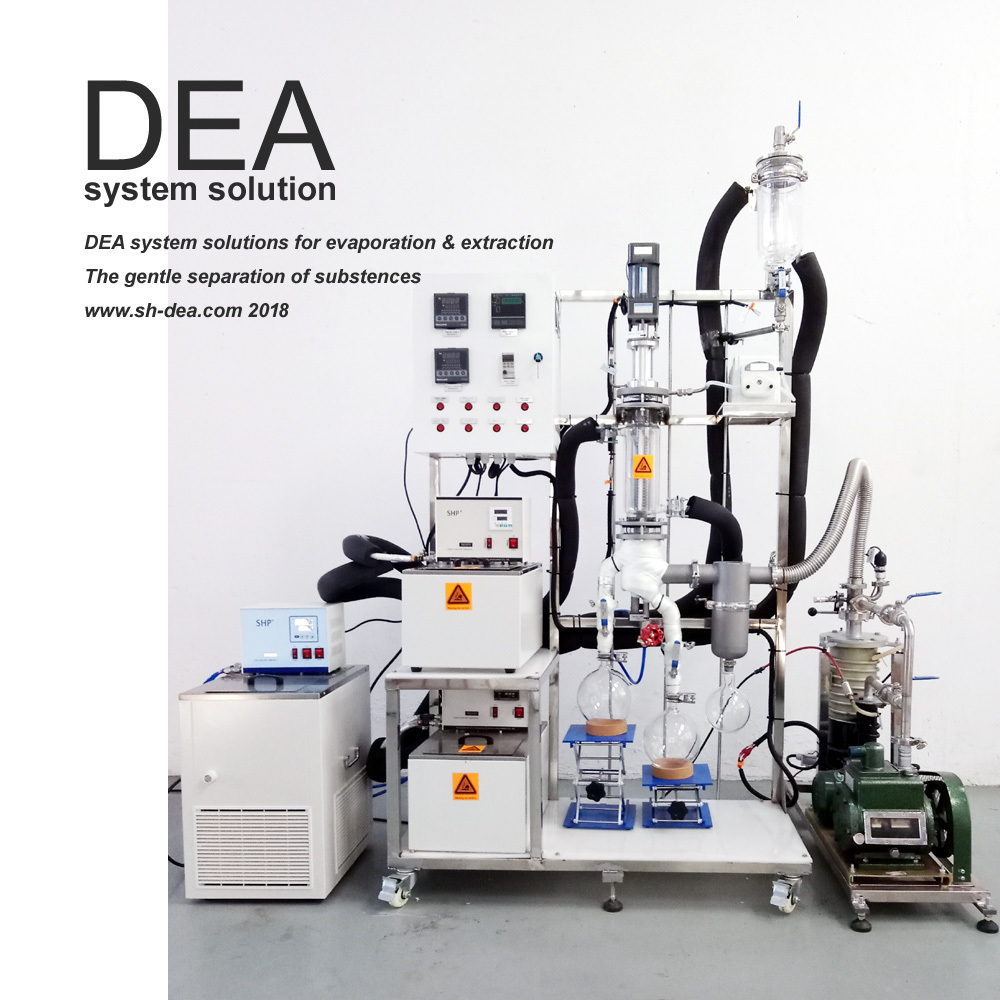

TYPE |

DZL-5G |

|

MATERIAL |

borosilicate glass/stainless steel 316 |

|

TEMPERATURE |

Room temp~200 ℃(Oil heater included) |

|

DIAMETER |

80 (mm) |

|

HEAT EXCHANGER SURFACE |

0.058 ( m 2 ) |

|

INNER CONDENSING SURFACE |

0.065 ( m 2 ) |

|

FEED AMOUNT |

150~1500 ( ml/h) |

|

ROTATION SPEED |

80-390rpm |

|

FILM SYSTEM |

Self-Clean Roll Filming System |

|

VACUITY |

0.001mbar(depend on the nature of material and vacuum pump)(vacuum pump not included) |

|

COLD TRAP |

Liquid nitrogen / stainless steel 316 |

|

FLOOR AREA |

length*width*height=1100*500*1700 (mm)(without pump) |

|

POWER |

2KW (without pump) |

|

VOLTAGE |

220V (we offer voltage transformer) |

If you want ger more details ,email us.

Our website:www.sh-dea.com

——Design

Different from the traditional wiped film evaporator design, the condenser is located inside the short path evaporator body.

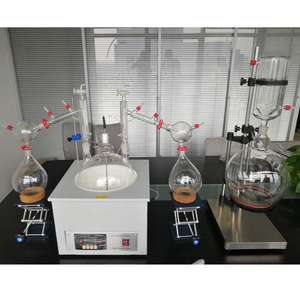

——Operation

Feed liquid is admitted into still under high vacuum, immediately spread into a very thin film and forced quickly down the evaporation surface. Heated walls and high vacuum drive the more volatile components (distillate) to the external condenser as the less volatile components (residue) continue down the cylinder. The resulting fractions, thus separated, exit through individual discharge outlets. Depending on application, the desired product is either the distillate or the residue fraction. Small amounts of condensable low MW compounds collect in cold trap upstream of vacuum system. For high solvent loads, an optional external condenser may be installed immediately downstream of the still.

——Particular features

Continuous distillation process.

Very low operating pressures up to 0.1Pa (100Pa=1mba). (The considerably lower pressure in the short path evaporator is obtained by the short distance for the vapours on their way from the evaporator surface to the condenser. )

The very low operating pressures ensure very low distillation temperatures and therefore a very gentle distillation is possible.

Short residence time. (Thanks to the short residence time, the low evaporation temperature and the immediate cooling of the concentrate, thermal stress and decomposition of the product can be minimized.)

High evaporation rates.

—— Fields of application

For the thermal separation of high molecular and high-boiling products.

For heat sensitive materials.