Your quotation will be replied in 24hours.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Mould material:

-

P20/718/738/NAK80/S136

-

Mould base:

-

HASCO Standard/LKM mould base

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

Mould cavity:

-

Singe Cavity/multi

-

Surface treatment:

-

polishing/texture/Mirror polish/electroplate

-

Mould type:

-

car parts injection mould manufacturer

-

Name:

-

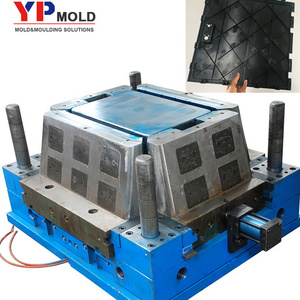

plastic basket moulding injection car spare parts mold

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YT-180803-1

-

Model Number:

-

Customized

-

Mould material:

-

P20/718/738/NAK80/S136

-

Mould base:

-

HASCO Standard/LKM mould base

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

Mould cavity:

-

Singe Cavity/multi

-

Surface treatment:

-

polishing/texture/Mirror polish/electroplate

-

Mould type:

-

car parts injection mould manufacturer

-

Name:

-

plastic basket moulding injection car spare parts mold

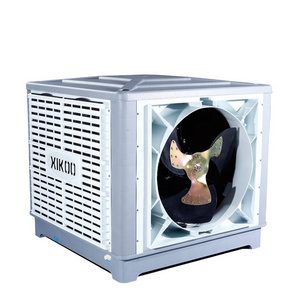

Plastic air cooler parts mould:plastic air cooler parts moulding injection air cooler parts mold

|

Mold Type

|

Plastic injection mold, overmolding

|

|

Design software

|

UG, ProE, Auto CAD, Solidworks, etc.

|

|

Main services

|

Prototypes, Mold design, Mold making, Mold tesing, low volume/ high volume plastic production

|

|

Certificate

|

ISO 9001:2008

|

|

Steel material

|

718H,P20,NAK80,S316H,SKD61, etc.

|

|

Plastic production Raw material

|

PP,PA6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc

|

|

Mold base

|

HASCO ,DME ,LKM,JLS standard

|

|

Mold runner

|

Cold runner, hot runner

|

|

Mold hot runner

|

DME, HASCO, YUDO,etc

|

|

Mold cold runner

|

point way, side way, follow way, direct gate way,etc.

|

|

Mold strandard parts

|

DME, HASCO, etc.

|

|

mold life

|

>300,000 shots

|

|

Mold hot treatment

|

quencher, nitridation, tempering,etc.

|

|

Mold cooling system

|

water cooling or Beryllium bronze cooling, etc.

|

|

Mold surface

|

EDM, texture, high gloss polishing

|

|

Hardness of the steel

|

20~60 HRC

|

|

Equipments

|

High speed CNC, standard CNC, EDM, Wire cutting, Grinder,Lathe, Milling machine, plastic injection machine

|

|

Lead time

|

25~60 days

|

|

Month Production

|

30 sets/month

|

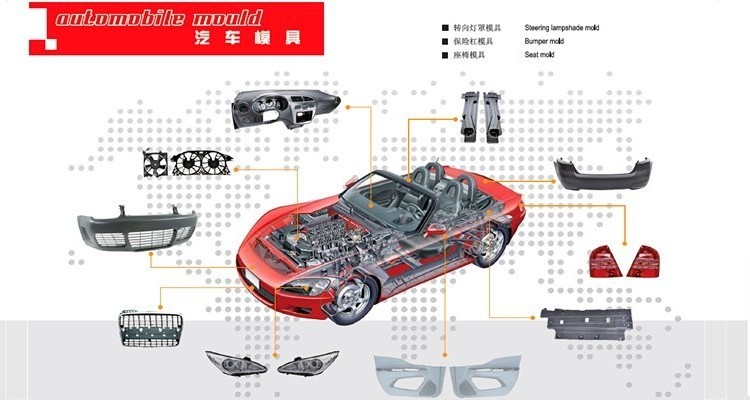

bumper mould,auto lamp mould,automobile interior parts mould,grill mould,dashboard mould,etc

crate mould,pallet mould,baby bathtub mould,storage box mould,children slider mould,toys mould,chair&table mould,etc

Q/C Inspect Moulds:

1.Mould Material Q/C

- Mould Steel Checking(Hardness, Crack ,Blow hole material defects )

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Machining Process Q/C

- Design checking (Part design, mould design,Including 2D drawing and 3D drawing)

- Each part of mould’s size checking after machining according to 2D drawing

- Mold Test (check mould running conditions and T1 samples)

3.Make sure to follow and checking each points of customer’s request before shipment

|

Machine

|

Working Range

|

Positioning Accurary

|

Work-piece Accurary

|

Max Spindle Speed

|

|

CNC Milling Machine

|

2500mm*1950mm*1100mm

|

0.002mm

|

0.02mm

|

0-4000rpm

|

|

HS Machining Center

|

1200mm * 800mm * 500mm

|

0.001mm

|

0.01mm

|

0-24000rpm

|

|

EDM

|

4000mm * 1700mm * 1000mm

|

0.002mm

|

0.02mm

|

---

|

|

Wire EDM

|

700mm * 450mm * 500mm

|

0.01mm

|

0.02mm

|

---

|

|

Low-speed Wire EDM

|

600mm * 400mm * 350mm

|

0.001mm

|

0.002mm

|

---

|

|

Deep-holedriller

|

2400mm * 1500mm * 1200mm

|

0.001mm

|

0.02mm

|

0-6000rpm

|

|

Item Name

|

Specification

|

Origin

|

Quantity

|

|

EDM

|

DK7740

|

Hangzhou

|

5

|

|

Die-spotting Machine

|

LS-200T

|

Ningbo

|

1

|

|

Drilling Machine

|

|

Hangzhou

|

4

|

|

Precision Horizontal Surface Grinding Machine

|

KGS-250

|

Taiwan

|

2

|

|

Hardness Tester

|

Testing Equipment

|

China

|

2

|

|

Coordinate Measuring Machine

|

KRONOS30-15-13

|

Italy

|

1

|

Anti-rust oil is painted first, then Plastic film

Finally

seaworthy wooden case outside

Shipping by sea or air,as custom require

1.Provide OEM/ODM service

2.Provide professional plastic mould design and manufacturing serivce

3.Provide plastic parts moulding/ printing/ painting service

4.Provide plastic parts assembly service

5.Provide plastic parts package service

6.Provide After-Sales service

Product Design

Professional Mold design team for 3D drawing product design,according to customer's detail requirement.

Mold Flow Analysis

Prediction of shrinkage marks, weld lines, warpage and tonnage of injection molding machines using mold flow analysis.

Mold Design

Our mold designers have rich experience in comprehensive development concept. The engineers attaches great importance to the mold production process, the design, trying to make with the longest use and fewer maintenance of mold.

Location of Yuntian

1.From Ningbo by train 1 hour.

2.From Yiwu by bus 3 hours.

3.From Shanghai by train 4 hours.

4.From Guangzhou by air 2 hours.