- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220-600V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SIEHE

-

Dimension(L*W*H):

-

Depending

-

Weight:

-

1200 KG

-

Filling range:

-

<400ml

-

Air source:

-

0.5-0.7 bar

-

Lid pressing:

-

Optional

-

Material:

-

SS304/SS316L

-

Explosion-proof:

-

Optional

Quick Details

-

Machinery Capacity:

-

4000BPH, Other, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Other

-

Filling Material:

-

Other

-

Filling Accuracy:

-

99%

-

Voltage:

-

220-600V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SIEHE

-

Dimension(L*W*H):

-

Depending

-

Weight:

-

1200 KG

-

Filling range:

-

<400ml

-

Air source:

-

0.5-0.7 bar

-

Lid pressing:

-

Optional

-

Material:

-

SS304/SS316L

-

Explosion-proof:

-

Optional

Product details

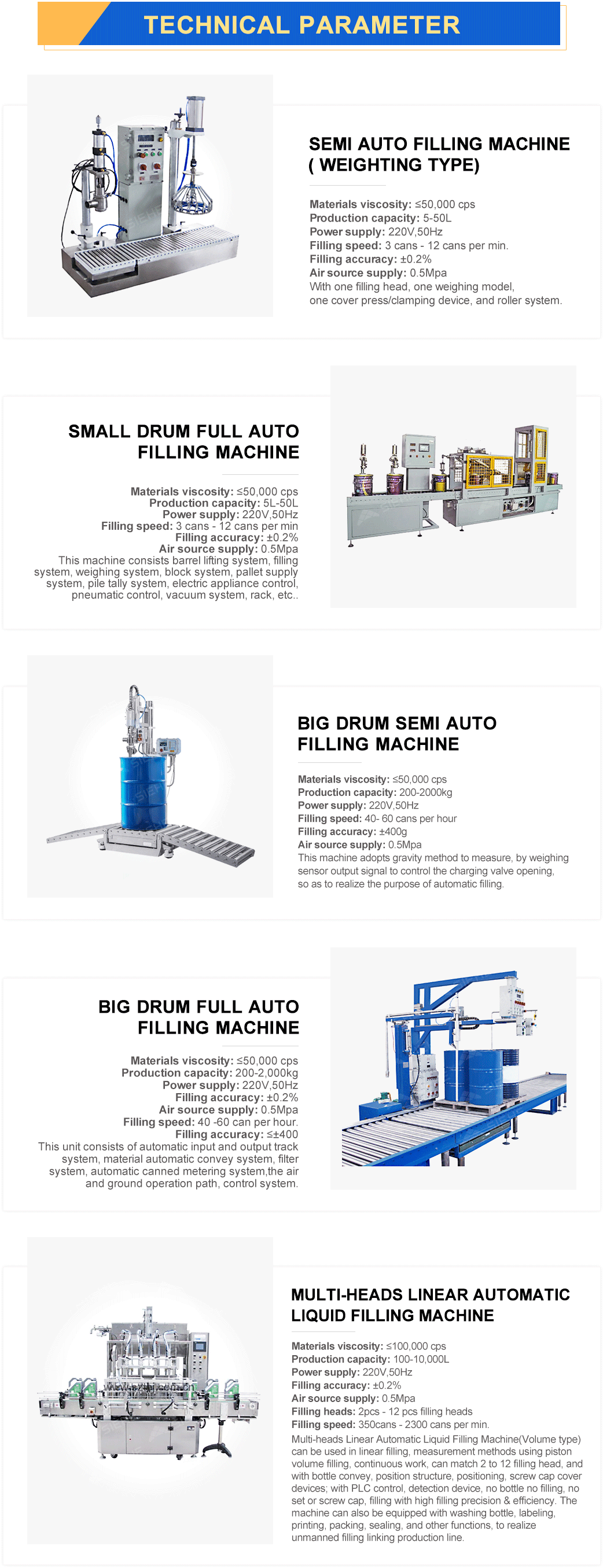

Filling machine is corollary equipment for Planetary Mixer or Multi-functional Mixer, its role is to pack the mixed materials, it can be divided into semi-auto and full auto type. Full auto filling machine consists of the frame, tube storage box, tube conveyor, pneumatic filling pump, automatic lid-arrangement and lid-on device, auto lid-pressing device and control system.

Normally it is used in quantitative filling for the containers which use insert lid at the end of the tube as the container. Vertical stepping to deliver the tubes, single head vertically fill the tube synchronously, intermittent shift working mode. Its main functions are automatic tube delivery, automatic quantitative vertical synchronous filling, automatically breaking wires after filling, automatically lid-arranging and lid-on device, automatically pneumatic lid-pressing, automatically detection, one operation for whole line management. Usually the materials will be from extrusion machine. Delivery pump for high-viscosity materials is also optional if the material viscosity is not so high.

Normally it is used in quantitative filling for the containers which use insert lid at the end of the tube as the container. Vertical stepping to deliver the tubes, single head vertically fill the tube synchronously, intermittent shift working mode. Its main functions are automatic tube delivery, automatic quantitative vertical synchronous filling, automatically breaking wires after filling, automatically lid-arranging and lid-on device, automatically pneumatic lid-pressing, automatically detection, one operation for whole line management. Usually the materials will be from extrusion machine. Delivery pump for high-viscosity materials is also optional if the material viscosity is not so high.

|

【Advantages】

|

Filling quickly, wide application

|

|

【

Convey capacity

】

|

Convenient operation, easy maintenance

|

|

【

Application industry

】

|

Filling with high precision, high degree of intelligence

|

|

【

Application materials

】

|

Environmental protection index outstanding and safe operation

|

Hot Searches