Beer brewing equipment: Brewhouse

Mash tun, Lauter tun, Boiling tun, Whirlpool tun

Two vessels, three vessels, four vessels brewhouse

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

No power

-

Dimension(L*W*H):

-

custom made

-

Weight:

-

KG

-

Machinery Capacity:

-

According to the product

-

Product Name:

-

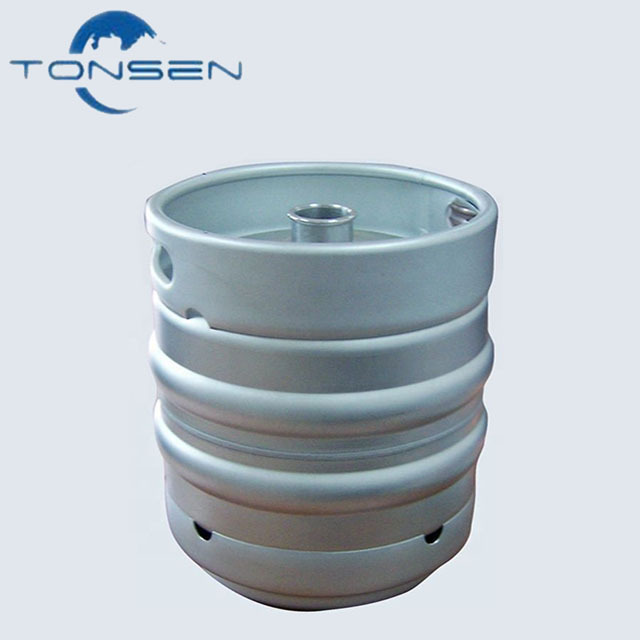

Beer Keg

-

Material:

-

Steel, SUS 304 Stainless Steel

-

Type:

-

Barrel

-

Usage:

-

Beer

-

Keywords:

-

Standard Beer Kegs

-

Product type:

-

Stainless Steel Strong Sealing Barrel

-

Application:

-

Beer Container

-

Color:

-

Customized

-

Logo:

-

Customer needing

-

Technology:

-

German method

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tonsen

-

Voltage:

-

No voltage

-

Power:

-

No power

-

Dimension(L*W*H):

-

custom made

-

Weight:

-

KG

-

Machinery Capacity:

-

According to the product

-

Product Name:

-

Beer Keg

-

Material:

-

Steel, SUS 304 Stainless Steel

-

Type:

-

Barrel

-

Usage:

-

Beer

-

Keywords:

-

Standard Beer Kegs

-

Product type:

-

Stainless Steel Strong Sealing Barrel

-

Application:

-

Beer Container

-

Color:

-

Customized

-

Logo:

-

Customer needing

-

Technology:

-

German method

Product Description

Material

: SUS304 sheet

Sizes : 10L, 15L,20L,30L, 50L

Stackable design

Reliable molding and welding are adopted to guarantee suitable precisionguten 10L 15L 20L 30L 50L beer kegs from China supplier,

View guten 10L 15L 20L 30L 50L, TONSEN Product Details from Jinan Tonsen Equipment Co., Ltd. on Alibaba.com

Sizes : 10L, 15L,20L,30L, 50L

Stackable design

Reliable molding and welding are adopted to guarantee suitable precisionguten 10L 15L 20L 30L 50L beer kegs from China supplier,

View guten 10L 15L 20L 30L 50L, TONSEN Product Details from Jinan Tonsen Equipment Co., Ltd. on Alibaba.com

|

Standard volume(L)

|

Volume

(L) |

Flange O.D.(mm)

|

Keg diameters (mm)

|

Full height (mm)

|

Container height

(mm) |

Neck height (mm)

|

Outer dimensions (mm)

|

Net Weight (kg)

|

|

15L

|

15+0.35/+0.1

|

Ø330±2

|

Ø313±2

|

324±2

|

267±2

|

14±2

|

Ø330×324

|

5.2±5%

|

|

20L

|

20+0.35/+0.1

|

Ø330±2

|

Ø313±2

|

386±2

|

331±2

|

14±2

|

Ø330×386

|

5.7±5%

|

|

30L

|

30+0.4/+0.1

|

Ø408±2

|

Ø395±2

|

365±2

|

325±2

|

14±2

|

Ø330×365

|

9.4±5%

|

|

50L

|

50+0.4/+0.1

|

Ø408±2

|

Ø395±2

|

520±2

|

480±2

|

14±2

|

Ø330×520

|

10.6±5%

|

1) Application: beer

2) Capacity: Euro 30L 50L ,20L US 1/2 ,1/4 , 1/6

3) Material: stainless steel SUS 304/2B

4) Logo: printing, embossed or engraved available

5) Stackable or unstackable available

6) Unbreakbale stainless steel outer shell

7) Different thickness of material available,1.2mm,1.5mm,2.0mm as per customers requirement.

8) Beads and chimes: The beads and chimes at the top and bottom of the kegs provide maximum protection against heavy impact and

the potential for bucking.

9) Hand holes: Secure handling of kegs is easy and convenient with the handle holes

10) Keg neck: The keg necks are built to withstand impact and are engineered to have long lasting fit for inserted keg valves

11) Rolling rings: The rolling rings provide additional strength to the body of keg

12) Welds: Advanced welding technology ensures smooth and consistent welds. The smooth interior surface lends itself to easy

cleaning and promotes resistance to sources that might infect or contaminate the liquid contents.

2) Capacity: Euro 30L 50L ,20L US 1/2 ,1/4 , 1/6

3) Material: stainless steel SUS 304/2B

4) Logo: printing, embossed or engraved available

5) Stackable or unstackable available

6) Unbreakbale stainless steel outer shell

7) Different thickness of material available,1.2mm,1.5mm,2.0mm as per customers requirement.

8) Beads and chimes: The beads and chimes at the top and bottom of the kegs provide maximum protection against heavy impact and

the potential for bucking.

9) Hand holes: Secure handling of kegs is easy and convenient with the handle holes

10) Keg neck: The keg necks are built to withstand impact and are engineered to have long lasting fit for inserted keg valves

11) Rolling rings: The rolling rings provide additional strength to the body of keg

12) Welds: Advanced welding technology ensures smooth and consistent welds. The smooth interior surface lends itself to easy

cleaning and promotes resistance to sources that might infect or contaminate the liquid contents.

Product Catalog

Related Products

Brewhouse

Fermentation tank

Beer brewing equipment: fermentation tank/fermenters

100 500 1000 1500 2000 3000 liters fermenter and so on

glycol water tank

Including, ice water tank, refrigerator, circulation pump, link pipeline, control system, solenoid valve, etc. The advantages are

short wine making time and fast cooling

short wine making time and fast cooling

chiller

Including: compressor, microcomputer display and so on. The advantages are simple structure, low failure rate, low energy consumption and small footprint

Packing & Delivery

Our Service

a.) Free consultation service before, during, and after sales;

b.) Project planning and design services;

c.) Free debugging instruction of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named port or station by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques;

g.) Provide 36 months complete warrantee for main parts and life-time maintenance service;The seller is responsible for the nature

damage of the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are attached with the

machinery for free;

b.) Project planning and design services;

c.) Free debugging instruction of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named port or station by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques;

g.) Provide 36 months complete warrantee for main parts and life-time maintenance service;The seller is responsible for the nature

damage of the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are attached with the

machinery for free;

Our Company

Our company is a

professional beer equipment manufacturer

. We are specialized in professional design,manufacture,installation and

commissioning of various beer equipments and supporting facilities.

We pay a lot attention to details and we have excellent after sales service.

We can supply all equipments for beer.

commissioning of various beer equipments and supporting facilities.

We pay a lot attention to details and we have excellent after sales service.

We can supply all equipments for beer.

Achievement

With years experience, we have export our equipment to over 20 countries, such as USA, UK, Germany, France, Mexico, Italy, India,

and so on.

Our enginners could help equipment installation, adjusting and worker training overseas.

and so on.

Our enginners could help equipment installation, adjusting and worker training overseas.

FAQ

1.Q:Are you a manufacturer?

A: Yes,we have been in providing the professional products in this field for 15 years.

2.Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

3.Q :How you pack the products ?

A: Normally as the export standard packaging or as you required.

4.Q: What is your available port of shipment?

A:Qingdao port,shanghai etc.

5.Q: Is customized available ?

A: Yes, according to your detailed drawings you provide

6.Q:Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

7.Q:After Sale Service

1. Warranty policy three years from shipment

2. We will send you the replacement after received the broken part

8.Q: Are you trading company or manufacturer ?

A: We are factory and welcome to visit us at any time.

9.Q: How long is your delivery time?

A: Generally single tanks need 20-30 days, for whole plant need 40-50days.

10.Q: Do you have CE and UL certification?

A: Yes.

11.Q: What is your terms of payment ?

A: 50% deposit and 50% before delivery.

A: Yes,we have been in providing the professional products in this field for 15 years.

2.Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

3.Q :How you pack the products ?

A: Normally as the export standard packaging or as you required.

4.Q: What is your available port of shipment?

A:Qingdao port,shanghai etc.

5.Q: Is customized available ?

A: Yes, according to your detailed drawings you provide

6.Q:Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

7.Q:After Sale Service

1. Warranty policy three years from shipment

2. We will send you the replacement after received the broken part

8.Q: Are you trading company or manufacturer ?

A: We are factory and welcome to visit us at any time.

9.Q: How long is your delivery time?

A: Generally single tanks need 20-30 days, for whole plant need 40-50days.

10.Q: Do you have CE and UL certification?

A: Yes.

11.Q: What is your terms of payment ?

A: 50% deposit and 50% before delivery.

Contact us

Hot Searches