- Product Details

- {{item.text}}

Quick Details

-

power:

-

induction brazing machine

-

feature:

-

portable, handheld

-

size:

-

small size

-

applications:

-

metal heat treatment

-

heat treatment:

-

brazing, hardening, annealing, curing, straightening, etc

-

certifications:

-

CE ISO etc

-

engineers:

-

available overseas

-

service:

-

best service before, after sale

-

poroduce name:

-

Induction Heating System Intelligent Digital Induction Heating Machine

-

inductors:

-

can be customized

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Canroon

-

Weight (KG):

-

70

-

power:

-

induction brazing machine

-

feature:

-

portable, handheld

-

size:

-

small size

-

applications:

-

metal heat treatment

-

heat treatment:

-

brazing, hardening, annealing, curing, straightening, etc

-

certifications:

-

CE ISO etc

-

engineers:

-

available overseas

-

service:

-

best service before, after sale

-

poroduce name:

-

Induction Heating System Intelligent Digital Induction Heating Machine

-

inductors:

-

can be customized

Induction metal heater for brazing welding for stainless steel/copper/aluminum heat treatment

Power: 10KW-60KW

Output Frequency: 10-40Khz Power and frequency can be custom-designed to be best suit customer's specific applications.

Using a new generation of control core, can output power to any metal to achieve rapid heating, a wide range of applications,

multi-circuit protection, with power, frequency, voltage, current display.

Induction metal heater has many advantages over flame or other brazing methods:

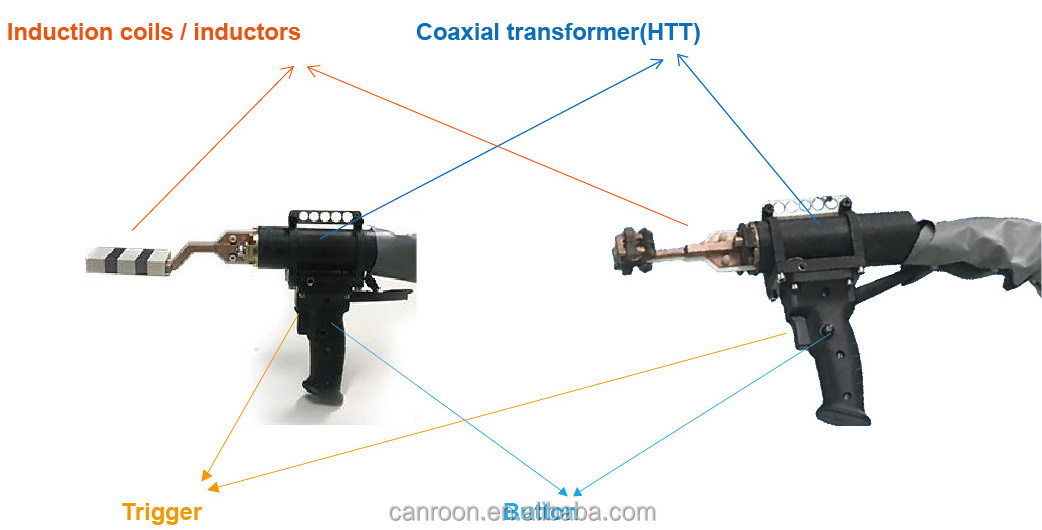

Canroon's Ultra-light and ultra-small handheld transformator,the minimum weight is only 3Kg.

High-speed heating is competent for 1s constant temperature control.

Fast running mode,heating time can be less than 1s.

1.safe,energy-saving.

2. Easy to automate.

3. For motor windings,do not damage insulation.

4.High energy density,heating speed,greatly improve production efficiency.

Adopt DSP full digital control system:

Brief introduction of high frequency induction machine heating equipment

for brazing welding and quenching :

Canroon is China leading manufacturer of induction heating machine, CR2100 series is our widely popular

both in China and oversea countries, digital control, modular design, LED display panel, HHT, detachable inductor,

soft induction cable, water cooling system.

Technical Parameters of High frequency induction machine heating equipment

for brazing welding and quenching :

|

Model |

Rated input voltage & frequency | Rated input power | Rated input current | Output frequency | Cooling water pressure / flow rate |

Dimension |

| CR2100-010B |

3-phase /400V (±20%) 50/60Hz |

10KVA | 15A |

10~40KHZ |

4~6 bar ≥12L/min |

L: 62.1mm W: 283mm H: 350mm |

| CR2100-015B | 15KVA | 22A | ||||

| CR2100-020B | 20KVA | 30A | ||||

| CR2100-025B | 25KVA | 37A | ||||

| CR2100-030B | 30KVA | 45A | ||||

| CR2100-035B | 35KVA | 53A | ||||

| CR2100-040B | 40KVA | 60A | ||||

| CR2100-050B | 50KVA | 75A |

4~6 bar ≥25L/min |

|||

| CR2100-060B | 60KVA | 90A |

Application Ranges for High frequency induction metal heater for brazing welding and quenching :

1. metal tube welding:such as copper tube, steel tube, and aluminum tube’s butt welding, plug welding and

welding sets.

2. alloy cutter welding:such as alloy turning tool, milling cutter, planer, saw blades, reamer, boring knife.

3.Heat treatment for various electric tools, such as gear and axes.

4.Heat treatment for machine tools,such as lathe deck and guide rail.

Applications:

Brazing, Annealing, Straightening, Hardening, Bolt Untighten, Shrink Fitting, Paint/Coating Removal, etc.

see the following detailed application of induction brazing for copper wire, heat exchanger, rotor coil, rotor bar,

short circuit ring, etc

HHT(hand held transformer) is easy to operate, and can be integrated with Robot Arm for automotion production,

two buttons to control the machine working:

Inductors are important part of induction heater, so it is precisely designed, manufactured by good quality material, and tested

many times before outgoing, it is detachable, and can be customized accoridng to your needs:

All of our equipment is packed in wooden case or carton box, delivery by sea, Express or by air.