- Product Details

- {{item.text}}

Quick Details

-

Design fuel:

-

Oil-fired,Gas-fired

-

Steam Pressure:

-

1.0/1.25/1.6/2.5Mpa

-

Certification:

-

ISO9001, CE

-

Fuel Type:

-

Coal/Biomass/Wood Chips(Pellets)-fired

-

Rated working pressure:

-

0.7-2.5Mpa(7-25bar)

-

Application Field:

-

Textile industry, textile factory

Quick Details

-

Place of Origin:

-

Henan, China

-

Dimension(L*W*H):

-

Depends

-

Weight:

-

320-2000 kg

-

Design fuel:

-

Oil-fired,Gas-fired

-

Steam Pressure:

-

1.0/1.25/1.6/2.5Mpa

-

Certification:

-

ISO9001, CE

-

Fuel Type:

-

Coal/Biomass/Wood Chips(Pellets)-fired

-

Rated working pressure:

-

0.7-2.5Mpa(7-25bar)

-

Application Field:

-

Textile industry, textile factory

Product Description

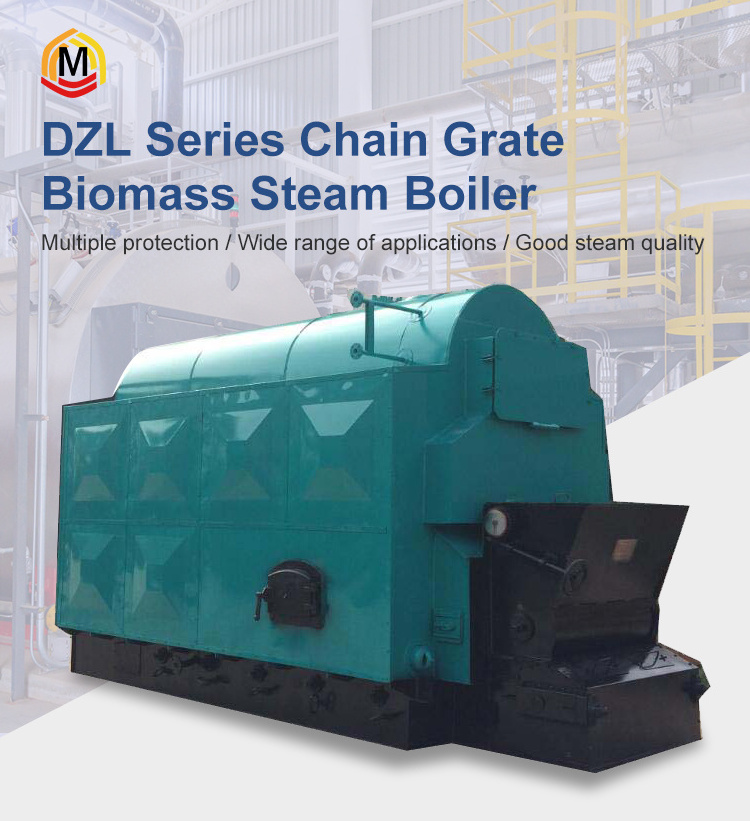

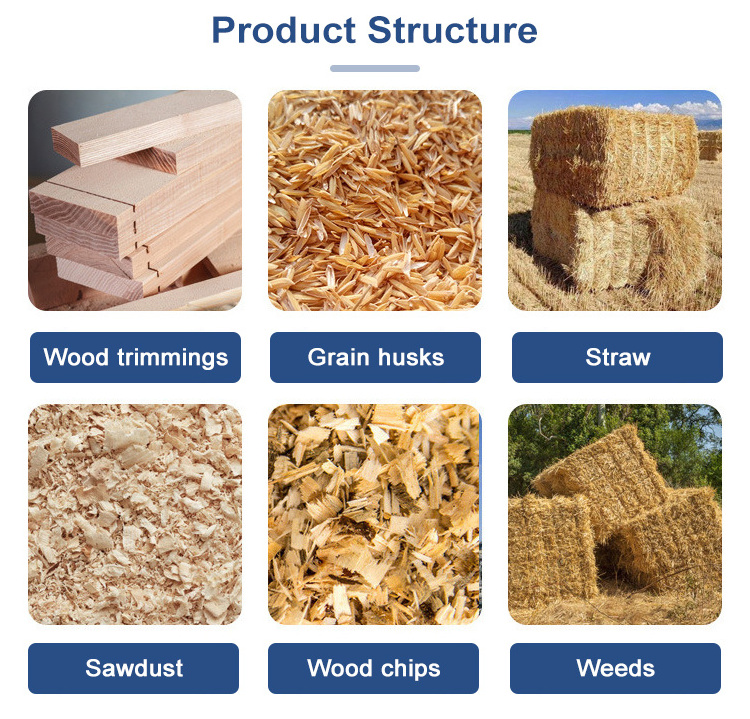

Biomass pellet fuel is an important research achievement in fuel application, it is the use of straw scale, rice rod, fuelwood, wood chips, peanut shells, melon seed shells, sugar beet pulp, bark and other waste crops, through crushing, mixing, extrusion, drying and other processes, finally made into pellet fuel. Its raw materials are widely distributed, advanced processing technology, biomass pellet fuel is known as green coal, is a kind of clean energy. As the fuel of the boiler, it has a long combustion time, high temperature in the intensification combustion furnace, and economic benefits, and no pollution to the environment at the same time, it can replace firewood, coal, natural gas, is an efficient energy-saving environmental protection products.

|

Item/Type

|

|

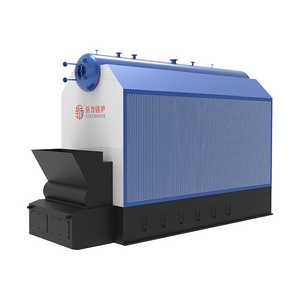

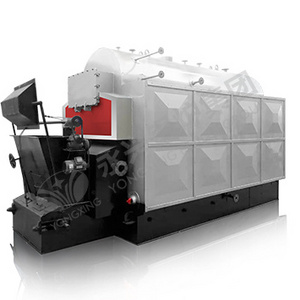

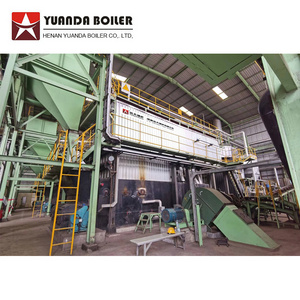

Single Drum Chain Grate Coal/Biomass Fired Steam Boiler

|

|

|

|

|

|

|

|

||||||||

|

Rated capacity t/h

|

|

1

|

2

|

4

|

6

|

8

|

10

|

12

|

15

|

||||||||

|

Rated steam pressure MPa

|

|

0.7/1.25

|

0.7/1.25/1.6

|

1.25/1.6

|

1.25/1.6

|

1.25/1.6

|

1.25/1.6

|

1.25/1.6

|

1.25/1.6

|

||||||||

|

Rated steam temperature ℃

|

|

170/194

|

170/194/204

|

194/204

|

194/204

|

194/204

|

194/204

|

194/204

|

194/204

|

||||||||

|

Feed water temperature ℃

|

|

20

|

|

|

|

|

|

|

|

||||||||

|

Boiler thermal efficiency %

|

|

78.1

|

80.2

|

82.3

|

82.5

|

82.5

|

82.9

|

82.9

|

83.1

|

||||||||

|

Body heating area m2

|

|

22.99

|

48.7

|

96.34

|

148.15

|

174.4

|

226.2

|

276

|

374.5

|

||||||||

|

Fuel & consumption

|

Fuel type

|

Class II Soft Coal, Biomass, Wood Chips, Wood Pellets,

Rice Husk, Palm Kernel Shell, etc. |

|

|

|

|

|

|

|

||||||||

|

|

Coal kg/h

|

101.79

|

198.25

|

347.75

|

520.36

|

693.81

|

863.08

|

1035.70

|

1291.51

|

||||||||

|

|

Biomass kg/h

|

147.11

|

286.52

|

502.57

|

752.03

|

1002.71

|

1247.34

|

1496.80

|

1866.50

|

||||||||

|

Size of boiler largest parts

mm |

Length

|

4600

|

5800

|

6700

|

7000

|

7300

|

7600

|

7600

|

8500

|

||||||||

|

|

Width

|

1900

|

2600

|

2700

|

3000

|

3000

|

3200

|

3200

|

3400

|

||||||||

|

|

Height

|

2900

|

3500

|

3500

|

3500

|

3500

|

3500

|

3500

|

3500

|

||||||||

|

Weight of boiler

largest parts ton |

|

18

|

22

|

30.1

|

40

|

21/14

|

23/17

|

23/19

|

21/24

|

||||||||

FAQ

Q1: How to get the best price quickly?

1)Please offer the boiler capacity & pressure you need, and the fuel you planto use, then we could offer the suitable boiler model.

2)Please provide your name, email address, WhatsApp/WeChat/Skype,andcompany name, then we will send the best price and boiler details immediately.

Q2: What about the installation and Commissioning?After you receive the boiler, we will guide you to make some preparation forinstallation, and our experts will offer overseas installation service if you need,and fly to the installation site within 72 hours.

Q3:What is the using life of your boiler?

Normally the boiler is designed for 15 years life span, but with correct operationand well maintenance, the boiler operation life will be longer.

Q4: Boiler Maintenance Period

Inspect every 2~3 weeks, mainly checking valves, pipe, flanges, if any leackage,repair it timely. While every quater, make a whole inspection and repair.

Q5:Terms of Payment

TT 30% of total contract value as down payment;T/T or LC 70% of total contract value before delivery.

lf you have special requirements, we can take a special approach.

Hot Searches