Weight:5 tons

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.8-1.5mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUSSMAN

-

Voltage:

-

220/380 or as request

-

Weight:

-

8000 kg

-

Marketing Type:

-

New Product 2024

-

Product Name:

-

Hydraulic K Span Arch Roof Roll Forming Machine

-

Material Thickness:

-

0.8-1.5mm galvanized steel

-

Roller Material:

-

45# Steel

-

Cutting Blade Material:

-

Cr12Mov Steel

-

Roller Station:

-

About 16 stations

-

Working Speed:

-

0-10m/min

-

Main Motor:

-

7.5kw

-

Hydraulic Power:

-

5.5kw

-

Transmission:

-

Chain

-

Application:

-

Roof

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-10 m/min

-

Rolling thinckness:

-

0.8-1.5mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUSSMAN

-

Voltage:

-

220/380 or as request

-

Weight:

-

8000 kg

-

Marketing Type:

-

New Product 2024

-

Product Name:

-

Hydraulic K Span Arch Roof Roll Forming Machine

-

Material Thickness:

-

0.8-1.5mm galvanized steel

-

Roller Material:

-

45# Steel

-

Cutting Blade Material:

-

Cr12Mov Steel

-

Roller Station:

-

About 16 stations

-

Working Speed:

-

0-10m/min

-

Main Motor:

-

7.5kw

-

Hydraulic Power:

-

5.5kw

-

Transmission:

-

Chain

-

Application:

-

Roof

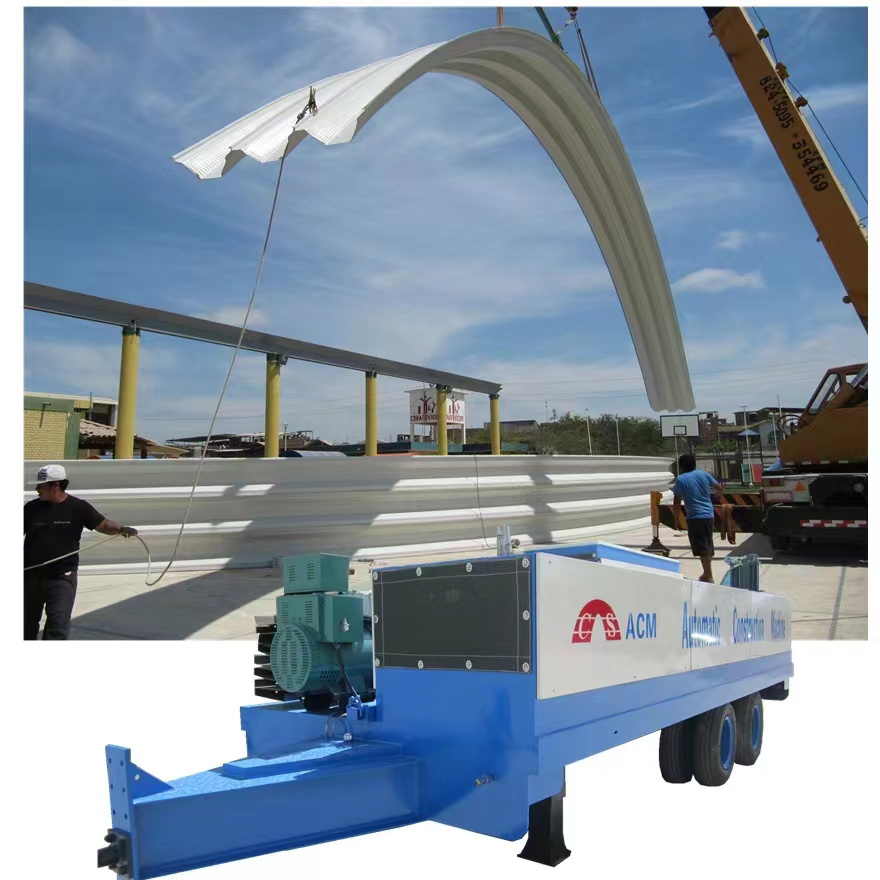

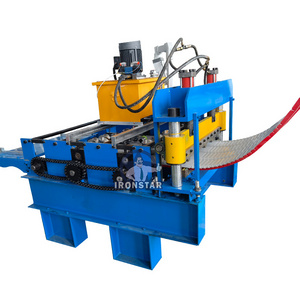

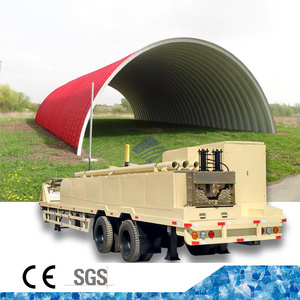

Product Description

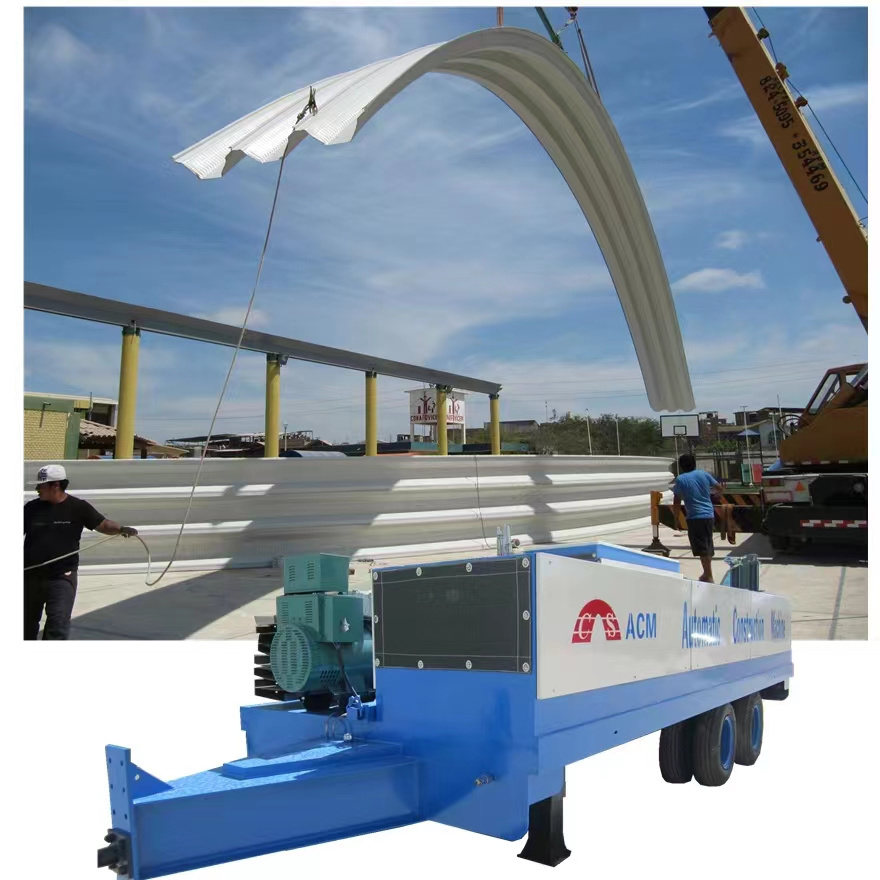

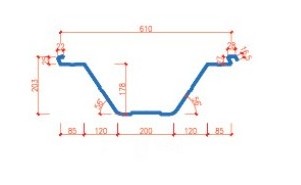

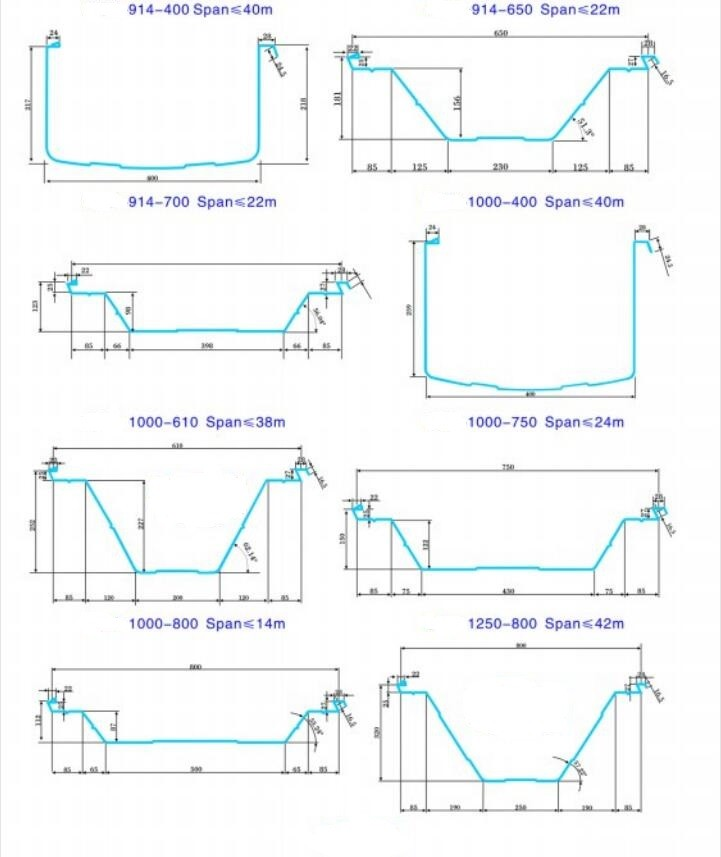

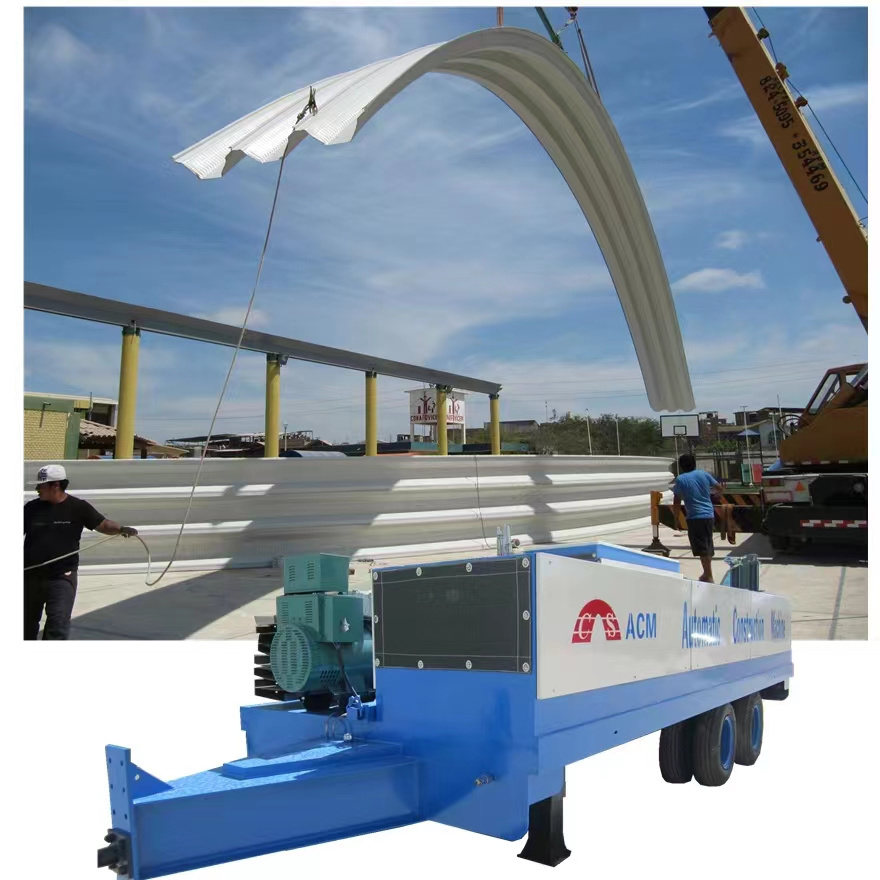

The no girder arch roof roll forming machine is designed and built to produce large span steel sheet for roofing panel. It is comprised of mechnical expansion decoiler, roll forming machine unit, hydraulic mould cutting device, curving panel machine unit, PLC control system, hydraulic system, run-out tables for straight and curve panels and all other accessories. Customer can choose mobile truck as foundation for flexible use.

Main Fetures & Components of the Machine

1. The structure is simple and the appearance of the machine is beautiful because we adopt the shape steel structure and process as a whole after welding, it has the ability of strong loading and stable operation when running the machine.

2. All the components of the machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

3. We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming.

4. It's very easy to install the equipment and suitable for producing in the factory.

5. The machine has features of low noise and high efficiency.

Machine List:

1. The structure is simple and the appearance of the machine is beautiful because we adopt the shape steel structure and process as a whole after welding, it has the ability of strong loading and stable operation when running the machine.

2. All the components of the machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

3. We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming.

4. It's very easy to install the equipment and suitable for producing in the factory.

5. The machine has features of low noise and high efficiency.

Machine List:

|

Serial No. |

Commodity & Description |

Quantity |

|

1 |

5 ton manual De-coiler |

1 set |

|

2 |

Leveing guiding devide |

1 set |

|

3 |

Servo feeding device |

1 set |

|

4 |

Main roll forming machine |

1 set |

|

5 |

Hydraulic station |

1 set |

|

6 |

Cutting device |

1 set |

|

7 |

Finished products tabel |

1 set |

|

8 |

PLC control system |

1 set |

|

9 |

Output table |

1 set |

|

10 |

Spare parts

|

1 set

|

Technical Parameter

|

Item NO. |

Description |

Offered Specification |

|

1 |

Product Line speed |

0-10 m per min |

|

2 |

Suitable material thickness |

0.8--1.5 mm |

|

3 |

Raw material |

Pre-paint Color Steel Coil yield strength≤G250MPa |

|

4 |

Dimension |

About 10400mm * 2250mm * 2300mm

|

|

5 |

Levelling device |

7 roller levelling |

|

6 |

Roller stations(stages) |

16 stations |

|

7 |

Roller material |

bearing steel, quenching treatment |

|

8 |

Shaft diameter |

Φ76mm ,material is 45# forge steel |

|

9 |

Transmission |

By chain 1.2 inch 20A double chain with longer shafts |

|

10 |

Material of chain |

45# forged steel with frequency quenching, 12A |

|

11 |

Material of cutting |

Cr12Mov with quench HRC58-62° |

|

12 |

Main motor power |

7.5kw |

|

13 |

Motor power of hydraulic station |

5.5kw |

|

14 |

Hydraulic station pressure |

12Mpa |

|

15 |

Machihne Weight |

10 Ton |

|

15 |

Tolerance |

6m+-1.5mm |

|

16 |

Frame |

H Beam |

Product Display

5 ton passive decoiler

Insider diameter of the un-coiler: 520-610mm

Weight:5 tons

Weight:5 tons

Hydraulic cutting

Hydraulic power: 5.5kw hydraulic system.

Blade Material: CR12Mov with heat treatment HRC58-62.

Tolerance: +-1.5mm

Control box

Power supplier: 380V, 50 Hz, Three Phase (adjusted with the requestment)

Length & quantity measurement automatically;

Length & quantity controlled by PLC

Length inaccuracy can be amended easily.

Control panel: Button-type switch and touch screen

The language in the touch screen: English and Chinese(as request)

Unit of length: millimeter (switched on the control panel)

Length & quantity measurement automatically;

Length & quantity controlled by PLC

Length inaccuracy can be amended easily.

Control panel: Button-type switch and touch screen

The language in the touch screen: English and Chinese(as request)

Unit of length: millimeter (switched on the control panel)

Passive outbale

It adopts welded steel and supported roller to transmit the products.

Size:6000*1000*1000mm

Size:6000*1000*1000mm

Application

Hot Searches