- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kida /Jinyu

-

Model Number:

-

GT-WSF-Ft-STI-C

-

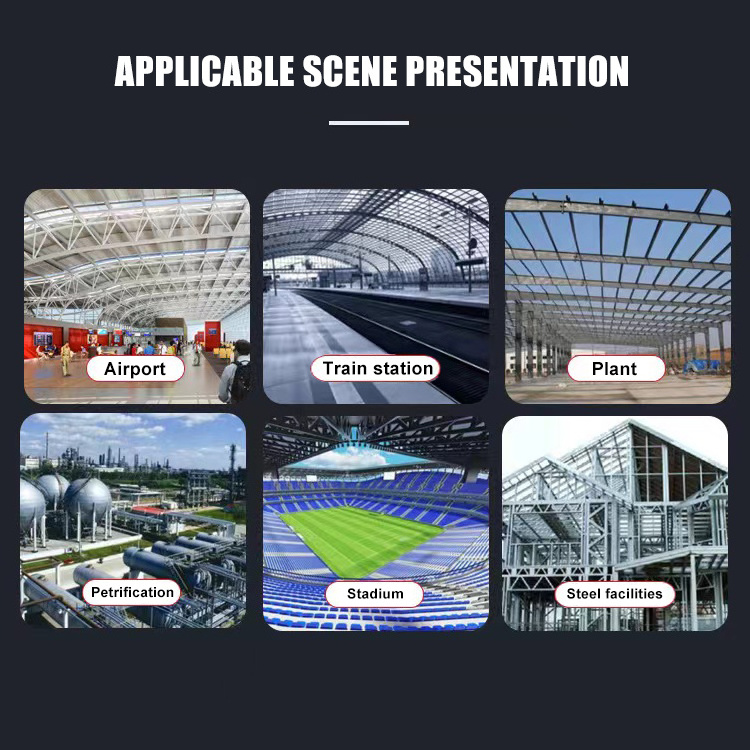

Application::

-

Fire protection of outdoor steel structures

-

Interval Time::

-

12 hours between each coat

-

Coating Thickness::

-

Each spray coat 1~3mm

-

Ambient temperature::

-

5-35℃

-

Relative humidity::

-

0-80%

-

Shelf life::

-

6 months from the date of production

-

Air pressure:

-

0.6~0.8MPa

-

Drying time (surface dry)::

-

≤24 hours

-

Adhesive strength::

-

0.34 MPa

-

pH value::

-

≥7

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

Fire Retardant Paint

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Kida /Jinyu

-

Model Number:

-

GT-WSF-Ft-STI-C

-

Application::

-

Fire protection of outdoor steel structures

-

Interval Time::

-

12 hours between each coat

-

Coating Thickness::

-

Each spray coat 1~3mm

-

Ambient temperature::

-

5-35℃

-

Relative humidity::

-

0-80%

-

Shelf life::

-

6 months from the date of production

-

Air pressure:

-

0.6~0.8MPa

-

Drying time (surface dry)::

-

≤24 hours

-

Adhesive strength::

-

0.34 MPa

-

pH value::

-

≥7

1. annual exports amounted to

$1,785,290

2. over

5,000,000

tons of paint exports annually

3. exports to more than

96

countries

4. Factory area of

60,000

square meters

5 .large-scale project works:

5426

items

6.

850

R&D staff and employees in total

7.

Top listed

Paint Manufacturer

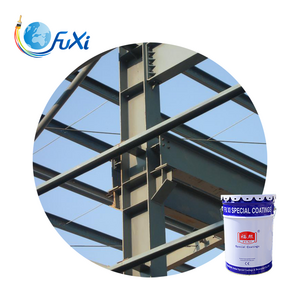

The function of expanding coatings is typically to form an expanding protective layer during a fire, providing insulation and flame resistance. When exposed to heat, these coatings expand to form foam or similar structures, preventing flames and heat from spreading to the surface underneath. This helps delay the spread of fire, giving more time for firefighting or evacuation efforts. Expanding coatings are commonly used for fireproof coating of materials such as steel structures, wood, walls, etc., enhancing the fire safety of buildings.

| KD-WSF-Ft-STI-C Exterior Non-Intumescent Steel Structure Fireproof Paint | |

| Drying time (surface dry) | ≤24 hours |

| Adhesive strength | 0.34 MPa |

| pH value | ≥7 |

| Thermal resistance | No change after 720 hours |

| Humidity resistance | No change after 502 hours |

| Freeze-thaw resistance | No change after 15 cycles |

| Acid resistance | No change after 360 hours |

| Alkali resistance |

No change after 360 hours

|

| UV radiation resistance | No change after 60 times |

| Maximum bending deformation | 36.9 mm(The coating thickness is 24mm.) |

| Fire resistance limit | >1.50 hours |

| Fireproof Paint & Fire Retardant Paint | |

| Exterior Intumescent Steel Structure Fireproof Paint | Fluorocarbon topcoat is a two-component fluorocarbon resin topcoat with excellent gloss and color retention. The product meets the requirements of HG/T 3792-2005. |

| Interior Intumescent Steel Structure Fireproof Paint | This product features thin coating thickness, strong adhesion, excellent fire resistance, and outstanding decorative effects. It is environmentally friendly and can be widely used for fire protection of indoor steel structures. |

| Exterior Non-Intumescent Steel Structure Fireproof Paint | This product is heavy-duty non-Intumescent steel structure fireproof paint and can be widely used for fire protection of outdoor steel structures in the petroleum and petrochemical industry, as well as in industrial and civil construction. |

| Interior Non-Intumescent Steel Structure Fireproof Paint | This product is a gypsum-based, water-based non-intumescent steel structure fire protection coating. It is environmentally friendly and can be widely used for fire protection of steel structures. |

| Decorative Fire Retardant Paint | This product is a two-component epoxy coating containing mica iron oxide pigments to enhance corrosion resistance and improve recoating performance after aging. |

| Tunnel Fire Retardant Coating | This product can be applied to the concrete surfaces of industrial and residential buildings, as well as tunnels on highways and railways. When exposed to fire, it forms a fire-resistant and heat-insulating protective layer to enhance the fire resistance limit of the structure. |

| Epoxy Zinc-rich Primer | epoxy zinc-rich primer is a two-component anti-corrosion paint with epoxy resin, zinc powder, additives, solvents, etc. |

| Epoxy Zinc-rich Primer | This product is a high zinc content, two-component oxygen-rich zinc primer. The zinc content complies with the requirements of HGT 3668-2009 Dry film zinc content level 2 in zinc-rich primers. |

| Epoxy Zinc-rich Primer | This product is a high zinc content, two-component oxygen-rich zinc primer. Zinc content meets dry film zinc level 1 requirements in SSPC-20 paint. |

| Low Surface Treatment Epoxy Paint | Epoxy universal wear-resistant paint is a two-component high-build epoxy resin paint with low solvent content and high volume solid content, which is suitable for new construction and maintenance of components. |

| Inorganic Silicate Zinc Rich Primer | This product is a two pack, solvent based inorganic zinc silicate primer. The dry film zinc content meets the requirements of HGT 3668-2009 dry film zinc content in paints. |

| Epoxy Glass Flake Paint | Epoxy wear-resistant paint is a two-component, high-solid epoxy paint containing glass flake pigments. The paint film is strong, wear-resistant and water-resistant. |

| Hot Sales paints/coatings | |

| Fireproof Paint | Decorative Fireproof Paint |

| Steel Structure Fireproof Paint | |

| Epoxy Floor Paint | Waterborne Epoxy Primer / Intermediate / Topcoat |

| Solvent-free Epoxy Primer / Intermediate / topcoat | |

| Epoxy Self-leveling Paint | |

| Color Self-leveling Concrete | |

| Waterborne Polyurethane Topcoat | |

| Interior Wall Coating | Universal Interior Sealer Primer |

| Pure Odor Interior Wall Paint | |

| Perfect Space Air Purifying Paint | |

| Inorganic Standard King Premium Interior Wall Paint | |

| Exterior Wall Coating | Stone Paint |

| Granite Topcoat | |

| Texture Paint | |

| Water-based Self-cleaning Finish Paint | |

| Elastic Exterior Paint | |

| Primer Paints Series | |

| Industrial Coatings | Fluorocarbon Topcoat |

| Acrylic Polyurethane Topcoat | |

| Silicone Heat-resistant Paint (200°C-600°C) | |

| Epoxy Mica Iron Intermediate Paint | |

| Epoxy Zinc-rich Primer | |

| Low Surface Treatment Epoxy Paint | |

| Inorganic Silicate Zinc Rich Primer | |

| Epoxy Glass Flake Paint | |

Our Factory

Our Laboratory

Custom Colors

OEM customization:

1.Send your lables or LOGO design

2.After confirm order,pls give us your design documents by PSD,AI or PDF.

3.We will process your packing send to you soon.

1. What types of wall paint do you offer?

We provide a range of wall paint options, including interior and exterior paints, as well as various finishes such as matte, eggshell, satin, and gloss.

2. How do I choose the right paint color for my space?

We offer a wide selection of paint colors and can provide color swatches or samples to help you decide.

3. What is the recommended surface preparation before painting?

For best results, ensure the surface is clean, dry, and free from dust, grease, and loose particles. Patch any cracks or holes, and consider using a primer for better adhesion.

4. Can your paints be used on different surfaces?

Yes, our paints are formulated to work on a variety of surfaces such as drywall, wood, concrete, and metal. Always check the product label for specific surface compatibility.

5. How many coats of paint are usually needed?

While one coat might suffice in some cases, two coats are recommended for an even finish and better coverage, especially when transitioning to a lighter color.

6. What is the drying time between coats?

Drying times can vary based on environmental conditions. As a general guideline, wait for the first coat to be touch-dry before applying the second coat. This can range from 2 to 4 hours.

7. Are your paints environmentally friendly?

Yes, we offer eco-friendly options with low VOC (volatile organic compounds) content, reducing harmful emissions and promoting better indoor air quality.

8. How do I clean and maintain painted surfaces?

Use a mild detergent and water to clean painted surfaces. Avoid abrasive cleaners, as they may damage the paint. Regular maintenance helps preserve the paint's appearance and longevity.

9. Can I paint over old paint without stripping it off?

In many cases, yes. Ensure the old paint is clean, well-adhered, and not peeling. Lightly sand the surface for better adhesion, and consider using a primer before applying a new coat.

10. Can I use your paints for exterior surfaces?

Absolutely. We offer exterior paints formulated to withstand weather elements, UV rays, and moisture, ensuring lasting beauty and protection for your outdoor spaces.

11. Do you offer custom paint matching?

Yes, we offer paint color matching services. Bring in a sample of the color you want, and our experts can create a custom paint color that matches it accurately.

12. What safety precautions should I take while painting?

Ensure proper ventilation, wear protective gear like gloves and goggles, and keep paint away from children and pets. Follow all safety instructions on the product label.

13. How do I dispose of leftover paint and empty cans?

Follow local regulations for paint disposal. Many communities have paint recycling programs. If allowed, dry out leftover paint before disposal or donate unused paint to local organizations.

Remember, specific guidelines can vary based on the product, so always refer to the product label and instructions for accurate information. If you have any more questions, feel free to contact our customer support team.