- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

8000*2050*1400

-

Weight:

-

3800 KG

-

Product name:

-

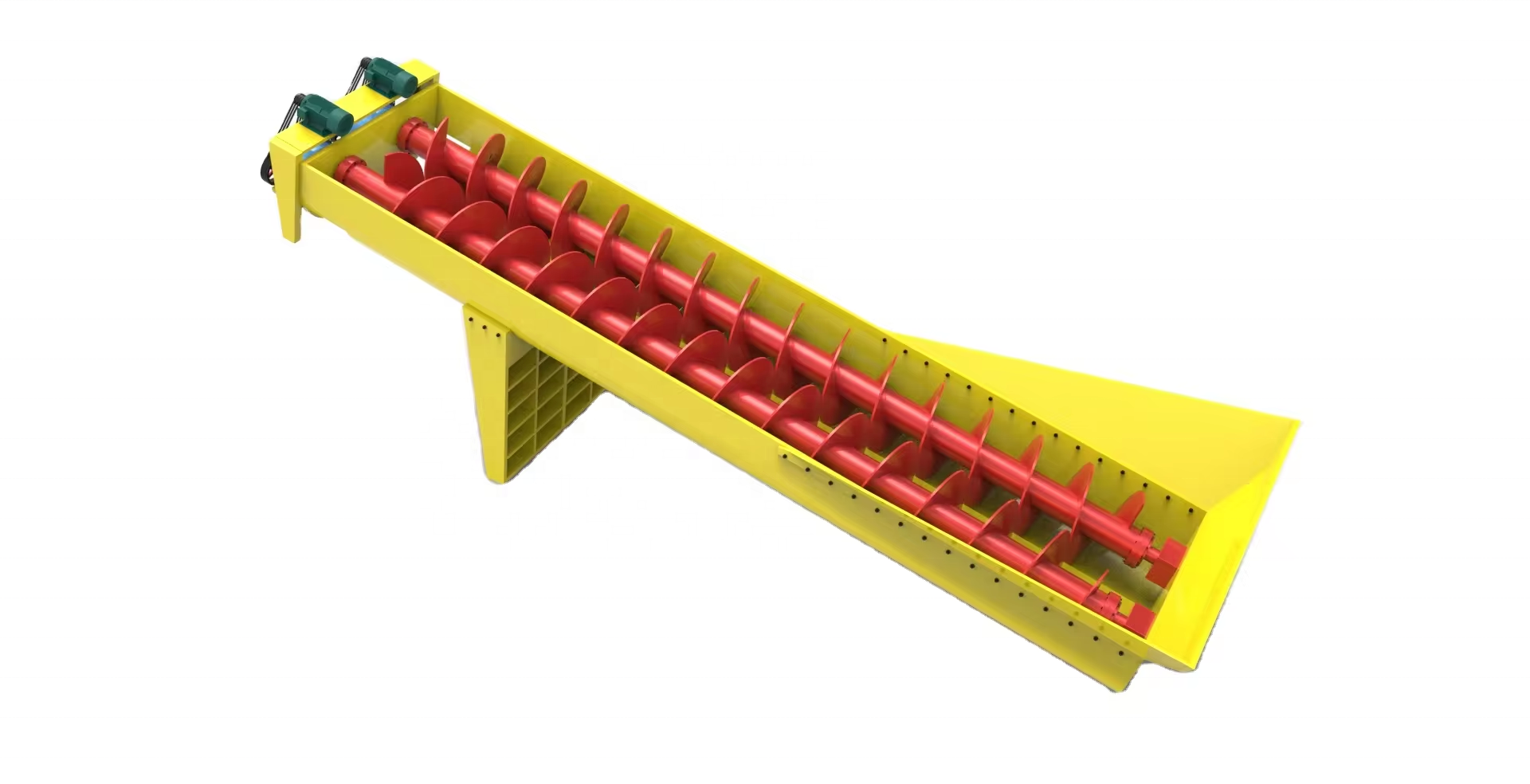

Sand Washing Machine

-

Model:

-

XL610 sand washing machine

-

Advantage:

-

High Clean Ratio

-

Color:

-

Customer's Requirement

-

Rotating spee:

-

32r/min

-

Max feeding size(mm):

-

10mm

-

Screw diameter:

-

610mm

-

Motor power:

-

5.5kW

-

Application:

-

Stone Sand Washing

-

MOQ:

-

1 SET

Quick Details

-

Capacity(t/h):

-

40-50

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UNIQUE

-

Dimension(L*W*H):

-

8000*2050*1400

-

Weight:

-

3800 KG

-

Product name:

-

Sand Washing Machine

-

Model:

-

XL610 sand washing machine

-

Advantage:

-

High Clean Ratio

-

Color:

-

Customer's Requirement

-

Rotating spee:

-

32r/min

-

Max feeding size(mm):

-

10mm

-

Screw diameter:

-

610mm

-

Motor power:

-

5.5kW

-

Application:

-

Stone Sand Washing

-

MOQ:

-

1 SET

Product Description

Screw sand washe

China Unique vibration new spiral sand washing machine is mainly used for sand processing, electric pole factory, building work site and concrete dam, various sands classifying and dewatering. This machine has three functions: washing, dewatering, classifying.

China Unique vibration new spiral sand washing machine is mainly used for sand processing, electric pole factory, building work site and concrete dam, various sands classifying and dewatering. This machine has three functions: washing, dewatering, classifying.

Features

1.High degree cleaning-up

2.Reasonable structure

3.Large capacity

4.Low power consumption

2.Reasonable structure

3.Large capacity

4.Low power consumption

Working Principle

The spiral sand washer adopts inclination of 15°,under the water tub, three weir plates form the sediment pool, the screw head is immersed in this pool, the screw is driven by electric motor through reducer rotating continuously, the fresh water is feeding from porous plate at bottom of sediment pool.

Technical Details

|

Model

|

XL508

|

XL610

|

XL762

|

XL915

|

2XL915

|

XL1115

|

2XL1115

|

|

Screw Diameter

(mm)

|

508

|

610

|

762

|

915

|

915

|

1115

|

1115

|

|

Length of Tub (mm)

|

6705

|

7225

|

7620

|

7585

|

7585

|

9782

|

9782

|

|

Max Feed Size (mm)

|

≤10

|

≤10

|

≤10

|

≤10

|

≤10

|

≤10

|

≤10

|

|

Capacity

(t/h)

|

20

|

40-50

|

50-75

|

100

|

200

|

175

|

350

|

|

Speed Of Screw (r/min)

|

38

|

32

|

26

|

21

|

21

|

17

|

17

|

|

Motor Power (kw)

|

5.5

|

7.5

|

11

|

11

|

2×11

|

15

|

2×15

|

|

Water Consumption (t/h)

|

6-60

|

6-63

|

9-63

|

10-80

|

20-160

|

20-150

|

40-300

|

|

Overall Dimensions

(L×W×H)(mm)

|

8000×2343

×1430

|

8000×2050

×1400

|

8545×2650

×3600

|

8500×2810

×3600

|

8420×3765

×3960

|

10970×3945

×4720

|

10970×5250

×4720

|

|

Weight

(t)

|

2.67

|

3.80

|

5.23

|

6.27

|

11.11

|

10.18

|

17.94

|

Working site

Packaging and Shipping

Packaging:

standard Container Packs or in Bulk.The electrical motor or spare parts will be packed by wooden case or steel

frame.Unique offers various ways of package, fumigation-free wooden cases, steel plate cases, or as the clients' request. Most of the time, the equipment will be loaded to the containers in the factory. Unique workers make sure all equipment are steady and fixed before close the door of the container, there will be no damage during transporation and shipment.

Shipping :we deliver the cargo to China's main sea ports,such as Qingdao,Tianjin,Shanghai etc.And then the container will be transported to your country by sea.

frame.Unique offers various ways of package, fumigation-free wooden cases, steel plate cases, or as the clients' request. Most of the time, the equipment will be loaded to the containers in the factory. Unique workers make sure all equipment are steady and fixed before close the door of the container, there will be no damage during transporation and shipment.

Shipping :we deliver the cargo to China's main sea ports,such as Qingdao,Tianjin,Shanghai etc.And then the container will be transported to your country by sea.

After-sales service support

1.more than 12 months' warranty period

2.Erection and Commissioning

3.Operator Training

4.Spare Parts Supply

Normally,Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed. To establish long term cooperation, we will regularly call and email our clients, to check the equipment working condition, offer suggestions for maintenance, and if necessary we will pay a visit to clients to solve the problems caused during equipment working.

1.more than 12 months' warranty period

2.Erection and Commissioning

3.Operator Training

4.Spare Parts Supply

Normally,Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed. To establish long term cooperation, we will regularly call and email our clients, to check the equipment working condition, offer suggestions for maintenance, and if necessary we will pay a visit to clients to solve the problems caused during equipment working.

Hot Searches