- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

3.75kw

-

Product name:

-

Tomato Paste Filling Production Line

-

Application:

-

Vegetable Paste

-

After-sales Service Provided:

-

Engineers

-

Function:

-

Multifunctional

-

Usage:

-

Food Processing Industries

-

Material:

-

304 Stainless Steel

-

Keywords:

-

Vegetable Fruits Cleaning Washing Line

-

Item:

-

Automatic Machine

-

Feature:

-

High Efficiency

Quick Details

-

Machinery Capacity:

-

oem

-

Brand Name:

-

Leadworld

-

Year:

-

OEM

-

Dimension(L*W*H):

-

OEM

-

Weight:

-

1500 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

3.75kw

-

Product name:

-

Tomato Paste Filling Production Line

-

Application:

-

Vegetable Paste

-

After-sales Service Provided:

-

Engineers

-

Function:

-

Multifunctional

-

Usage:

-

Food Processing Industries

-

Material:

-

304 Stainless Steel

-

Keywords:

-

Vegetable Fruits Cleaning Washing Line

-

Item:

-

Automatic Machine

-

Feature:

-

High Efficiency

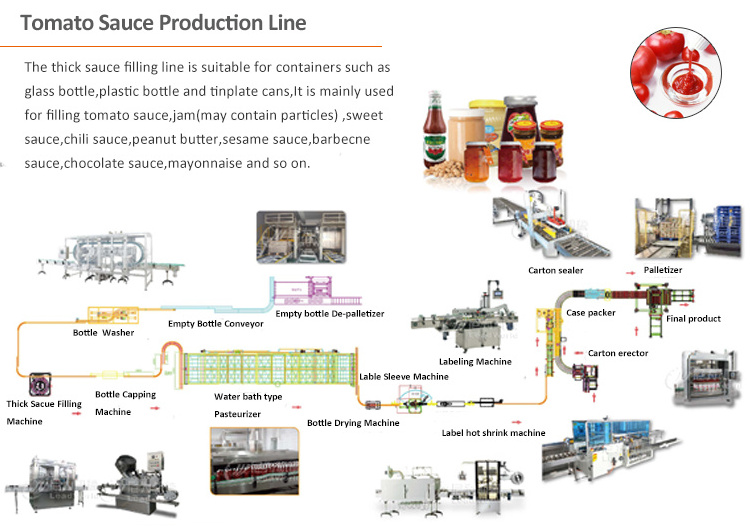

Product Description

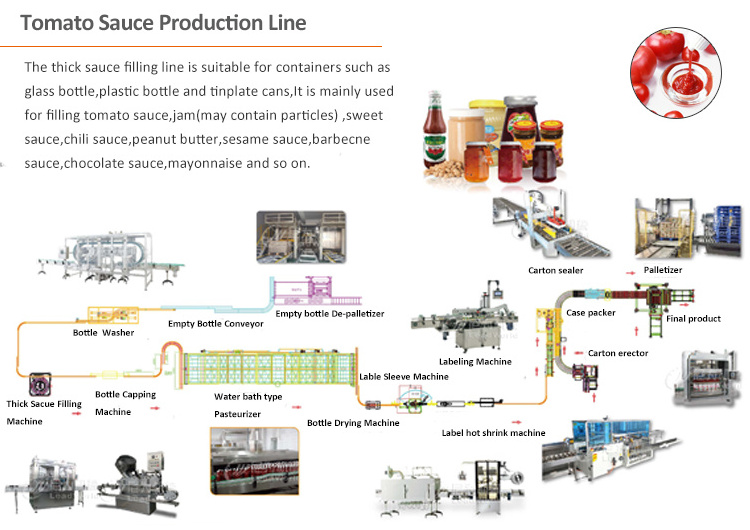

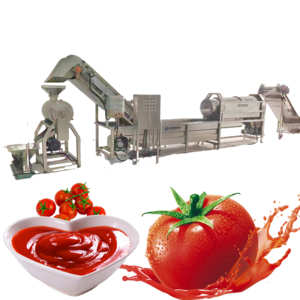

Tomato Paste Filling Production Line

1.tomato (fruit or vegetable) → 2.Digging nuclear →3.Turnover→4.Soda water spraying→5.Peeler and cleaner → 6.pre-cooked → 7.cooling → 8.pick → 9.go hair→10.Slicer →11.Filling(←Botte washing←Depalletizer)→12.Pouring juice→13.Exhauster→14.Sealing→15.Canned tomato→16.Sterilization→17.Dryer→18.Cans Palletizer

→

19.Warehousing→20.Labeler→21.Finished product→22.Case packer→23.Case Palletizer→24.Shipments

Filling Machine Parameters:

Related products

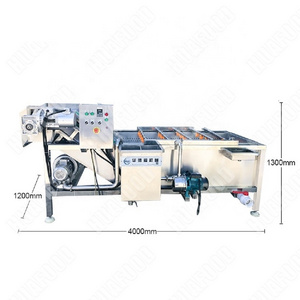

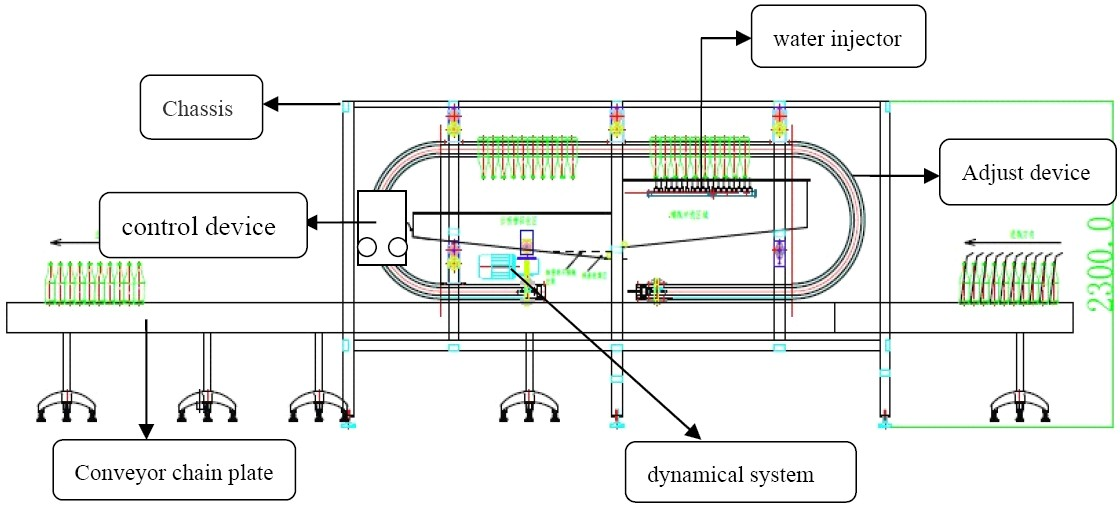

Bottle washing machine

Main Features:

High Pressure Flushing Bottle Washing Machine mainly applies to glass bottle and canned container washing, temperature can be adjusted by machine automatically;

It adopts circulating hot water、warm water preheating、cold water cleaning as well as other methods. It has water and energy saving functions

Technical Parameters:

Diameter of bottles:50-200mm

Height of bottles:50-310mm

Capacity of washing:150bottles/min

Water injection power:0.2-0.4MPa

Water temperature >75℃

Washing time:1.5 seconds

Drain time:4 seconds

Consumption of water: 2-4T/H

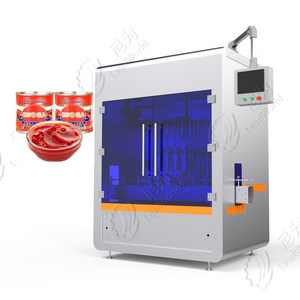

Filling machine

1. Vacuum Preventing Leaking System

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame,Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-0.5%-1%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

10.Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric sensor

|

Model

|

Filling Volume

|

Air Pressure

|

Air Consumption

|

Filling Accuracy

|

Total Power

|

|

LW-FMV-4A

|

10-60g 30-100g 50-250g 100-500g 200-1000g 500-2500ml 1000-5000ml |

5-6kg/cm2 |

260L/M

|

Liquid<=0.5%

Sauce<=1% |

3ph,AC380V 50/60HZ 1.369KW

|

|

LW-FMV-6A

|

|

|

280L/M

|

Liquid<=0.5%

Sauce<=1% |

3ph,AC380V 50/60HZ 1.69KW

|

|

LW-FMV-8A

|

|

|

360L/M

|

Liquid<=0.5%

Sauce<=1% |

3ph,AC380V 50/60HZ 2.07KW

|

|

LW-FMV-10A

|

|

|

440L/M

|

Liquid<=0.5%

Sauce<=1% |

3ph,AC380V 50/60HZ 2.82KW

|

|

LW-FMV-12A

|

|

|

500L/M

|

Liquid<=0.5%

Sauce<=1% |

3ph,AC380V 50/60HZ 2.82KW

|

Aluminum foil sealing machine(Roll Film)

1.

Descriptions:

The wide-mouth bottle sealing machine is widely used in various plastic cups/bowls/boxes/bottles/can

seals, sealing one to six at a time; the sealing is firm and efficient, the automation is high, the operation

is simple and quick, the performance is stable, and it is easy to maintain; It can be used in a single

machine or in a production line, which greatly reduces the labor intensity and labor cost of workers and

improves production efficiency.

Packaging container

(Customized on demand) is not limited to round, long square, polygonal and other shaped containers

2. Performance characteristics

Automatic film cutting, automatic film winding, automatic color code positioning, intelligent PLC control

system, automatic adjustment of sealing heat sealing time and film length, automatic counting function,

automatic constant temperature, one button start and stop;

3. Workflow

Delivery bottle → light eye count → automatic positioning sealing → film cutting, film removal, film

collection → automatic product delivery

Automatic double side labeling machine

Features:

LW-901 is mainly composed of SUS304 Chassis; Chain Plate Conveyor Line;Separation Correction; Synxhronition Crimping;Dual-head;Universal Adjustment Sponge Wheel and other institutions,use.Siemens PLC,touch screen;Servo motor as the main compenents,control devices run at high speed.Equipment safety,efficiency,and stability;comply with GMP,CE specifications.

Friendly operation interface,easy setting.

Mainfunction: product count, output setting, parameters memory, equipment state monitoring,device failure automatic shutdown,alarm fault location and help information.

Hot Searches