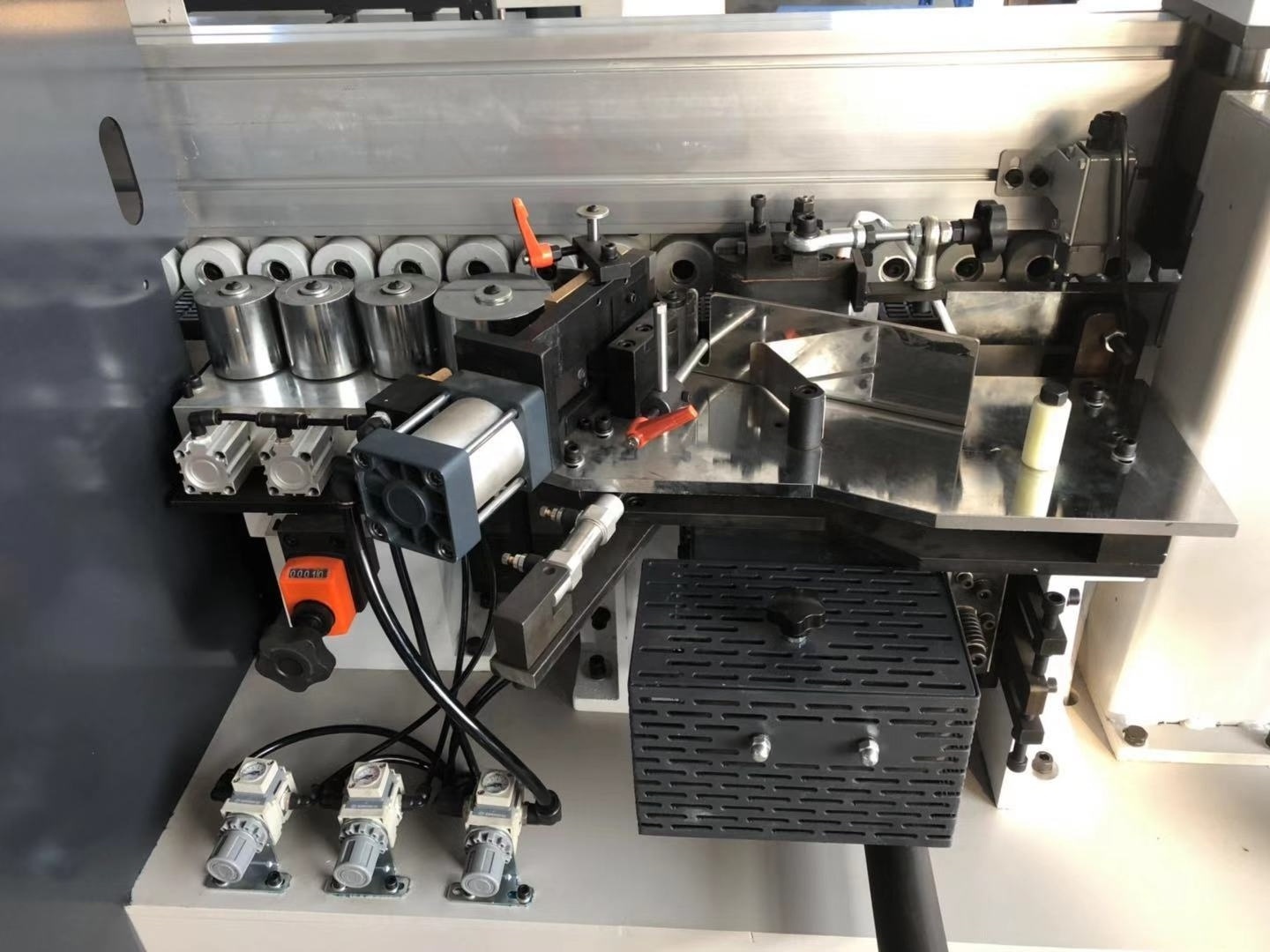

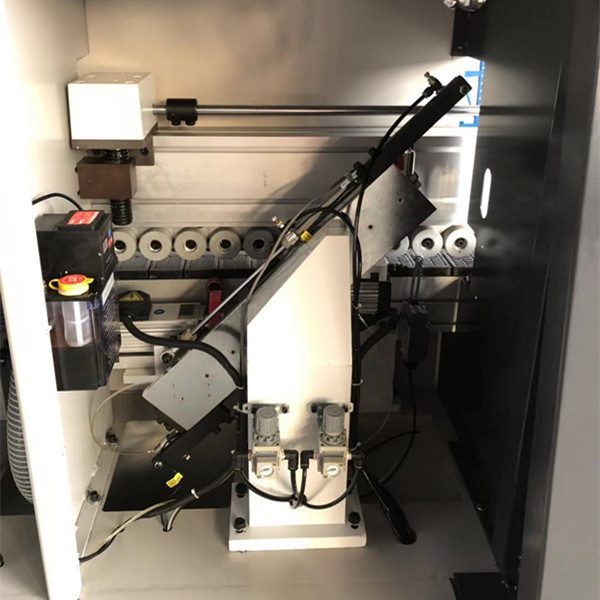

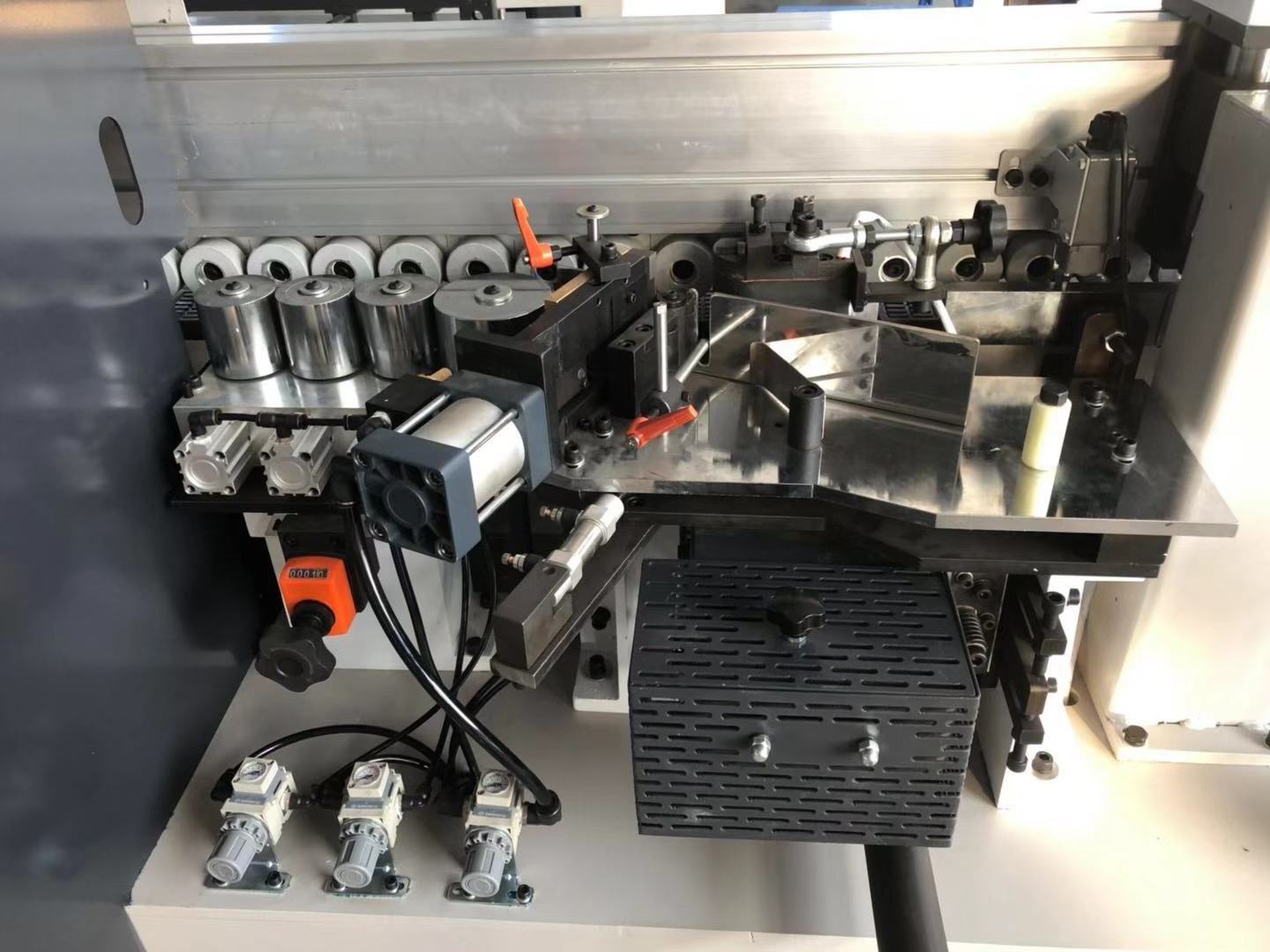

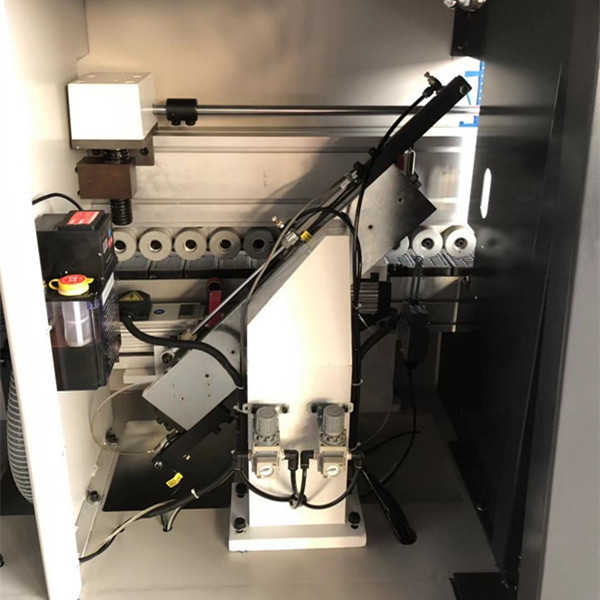

Rough/Fine trimming mechanism is used for repairing the excess edge materials, adopting automatic tracking and high frequency motor fast cutting structure to ensure the trimming plates smoothly.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4600*900*1600mm

-

Power (kW):

-

10KW

-

Weight (KG):

-

1900 kg

-

Panel Feed Speed(m/min):

-

25m/min

-

Weight:

-

1900kgs

-

Power(W):

-

10kw

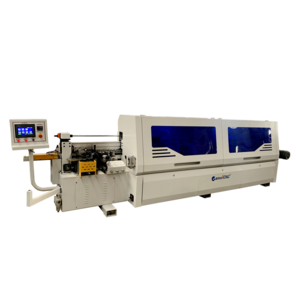

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HYSEN

-

Voltage:

-

Optional

-

Dimension(L*W*H):

-

4600*900*1600mm

-

Power (kW):

-

10KW

-

Weight (KG):

-

1900 kg

-

Panel Feed Speed(m/min):

-

25m/min

-

Weight:

-

1900kgs

-

Power(W):

-

10kw

Function: Gluing Press---End Cutting---Rough Trimming---Fine Trimming---Scraping--Buffing

|

Model

|

HS-506

|

|

Edge Banding Tape Thickness

|

0.4-3mm

|

|

Panel Thickness

|

10-60mm

|

|

Panel Width

|

≥60mm

|

|

Panel Length

|

≥80mm

|

|

Feed Speed

|

12-25m/min

|

|

Air Pressure

|

0.7Mpa

|

|

Total Power

|

10kw

|

|

Overall Size

|

4600mm*900mm*1600mm

|

Glue mechanism adopts a special structure to gelatinize the plated and coat materials uniformly, which ensures a more solid conglutination.

End trimming mechanism through a precise guide track movement, adopts automatic tracking and high frequency motor fast cutting structure to ensure the cutting surface smoothly.

Scraping unit works for a perfect finishing of the applied edge.

Buffing device adopt the board processed by cotton polishing wheel, by end-polishing to make a more smooth surface.