- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sijihuo

-

Model Number:

-

Abrasive Disc

-

Use:

-

Polishing

-

Application:

-

Industrial Furnaces

-

Product name:

-

Brown corundum

-

Color:

-

brown

-

Size:

-

Customizable

-

Raw material:

-

High Alumina Bauxite

-

Usage:

-

Polishing

-

Bulk Density:

-

2.0-2.5g/cm3

-

Certificate:

-

ISO9001

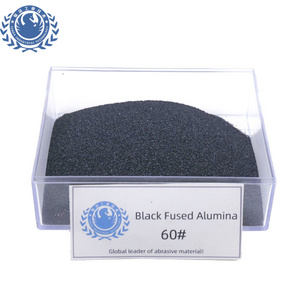

Quick Details

-

Type:

-

blasting media

-

Abrasive Grain Sizes:

-

12-220#

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sijihuo

-

Model Number:

-

Abrasive Disc

-

Use:

-

Polishing

-

Application:

-

Industrial Furnaces

-

Product name:

-

Brown corundum

-

Color:

-

brown

-

Size:

-

Customizable

-

Raw material:

-

High Alumina Bauxite

-

Usage:

-

Polishing

-

Bulk Density:

-

2.0-2.5g/cm3

-

Certificate:

-

ISO9001

Abrasive brown fused aluminum oxide /alumina/ corundum

Brown corundum,usually called emery,is made of bauxite,carbon materials and iron dust.Put the three kinds of raw materials in the electric furnace and then melt,reduction,Finally get the brown corundum.The chemical composition of the brown corundum is Al2O3,and the content is 94.5%-97%,the other part contains a small amount of Fe,Ti and so on.

Physical properties:Crystal form trigonal system

Chemical properties:amphoteric and react with acid,slightly acid corrosion in aqua regia and hydrofluoric, react with alkali,the Knoop hardness 2000-2200kg/mm2,Mohs hardness 9.0,color dark brown and after burning,it gets to be deep blue,the melting point 2250C and the highest use temperature 1900C.

The main component of the brown corundum is alumina,the content of the alumina determines the degree of the quality,the less content of the alumina,the lower hardness.Higher toughness than SIC,the bulk density≥3.85g/cm3.high refratoriness up to 1850C.

| Item | Specification | Al2O3 | Fe2O3 | SiO2 | SiO2 | Magnetic matter | |

| 4#-80# | ≥95% | ≤0.3% | ≤1.5% | ≤3.0% | ≤0.05% | ||

| F | 90#-150# | ≥94% | ≤0.3% | ≤1.5% | ≤3.0% | ≤0.03% | |

| 180#-240# | ≥93% | ≤0.3% | ≤1.5% | ≤3.5% | ≤0.02% | ||

| Abrasives | 8#-80# | ≥95.0% | ≤0.2% | ≤1.2% | ≤3.0% | ≤0.05% | |

| P | 90#-150# | ≥94.0% | ≤0.2% | ≤1.2% | ≤3.0% | ≤0.03% | |

| 180#-240# | ≥93.0% | ≤0.3% | ≤1.5% | ≤3.5% | ≤0.02% | ||

| W | 1#-63# | ≥92.5% | ≤0.5% | ≤1.8% | ≤4.0% | - | |

| Refractory material | Section sand | 0-1mm 1-3mm 3-5mm 5-8mm 8-12mm | ≥95% | ≤0.3% | ≤1.5% | ≤3.0% | - |

| 25-0mm 10-0mm 50-0mm 30-0mm | ≥95% | ≤0.3% | ≤1.5% | ≤3.0% | - | ||

| Fines | 180#-0 220#-0 320#-0 | ≥94.5% ≥93.5% | ≤0.5% | ≤1.5% | ≤3.5% | - |

Application:

As corundum has excellent high temperature properties and mechanical strength and other properties, which is widely used in metallurgy, machinery, chemicals, electronics, aviation and defense and many other industrial fields. Its main use is as follows.

due to high temperature resistance, corrosion resistance, high strength and other properties, it is used as steel sliding nozzle, smelting rare precious metals, special alloys, high purity metal, glass wire drawing, the production of laser glass crucible and utensils; , Such as refractory materials, ceramics, ironmaking blast furnace lining (walls and tubes); physical and chemical utensils, spark plugs, heat and oxidation resistant coating. SiO less than 0.5% of the low-silicon sintered corundum brick is carbon black, boron chemical, chemical fertilizer, ammonia synthesis furnace and the furnace for the special furnace lining.