- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LC-2101

-

appearance:

-

liquid coating

-

usage:

-

UV embossed

-

adhesion:

-

excellent

-

substrate:

-

OPP film,Bopp film or printed paper

-

other name:

-

spot uv screen

-

Delivery Time:

-

fast and timely

-

coating machine:

-

silk screen printing UV machine

-

Mesh:

-

100-160T

-

effect:

-

spot UV gloss

-

drying method:

-

UV dryer lamp

Quick Details

-

Printing Type:

-

Screen printing

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LCCX

-

Model Number:

-

LC-2101

-

appearance:

-

liquid coating

-

usage:

-

UV embossed

-

adhesion:

-

excellent

-

substrate:

-

OPP film,Bopp film or printed paper

-

other name:

-

spot uv screen

-

Delivery Time:

-

fast and timely

-

coating machine:

-

silk screen printing UV machine

-

Mesh:

-

100-160T

-

effect:

-

spot UV gloss

-

drying method:

-

UV dryer lamp

UV silk screen printing ink with foaming effect

Screen printing UV varnish LC-2101

Product description :

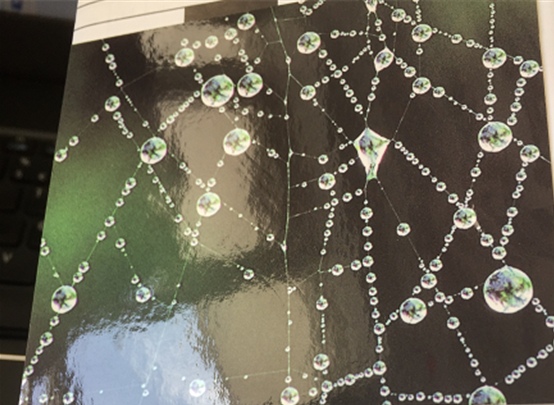

LC-2101 emboss screen varnish, screen printing UV varnish is designed for screen printing on printed paper or BOPP films to create embossing (high thickness) visual effect. It is mainly used for the surface coating of matt BOPP or OPP film base materials and paper substrates. On the part need outstanding or highlight of the printed packages, coating screen printing UV varnish, after UV curing achieve the effect of light gloss. Compared with the surrounding pattern, the glazing pattern looks like bright and beautiful, a strong stereo feeling, can present a unique artistic effect.

Product features:

1. Fast curing speed , solvent free, environment-friendly product.

2. Good adhesion, excellent folding resistance, high hardness. Good anti-scratch and smoothness.

3. Excellent chemical resistance, can withstand most organic solvents and water, acid, alkali, etc.

4. Excellent printing adaptability, good flow property and defoaming performance.

5. Compared with LC-2100, LC-2101 has a mild odor; but it is still belong low smell silk screen printing UV varnish.

Application machine:

Automatic screen printing machine, semi-automatic UV silk screen printing machine or manual screen machine.

General properties:

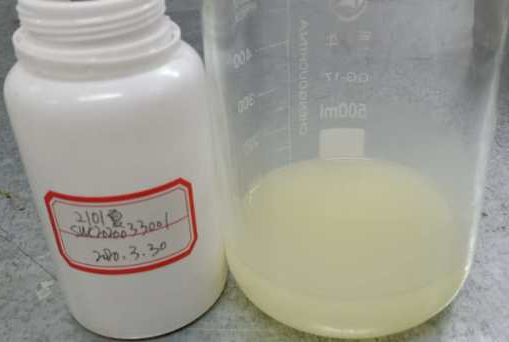

Appearance: yellowish to milky viscous liquid

Viscosity: 1500±200cps ( 3#/25 ℃ ) or 60±5s (T4#,60 ℃ )

Solid percent: 100%

Gloss degree(angel 60 °) : ≥90°

Curing speed: 18m/min or 120 mj/cm 2

Appearance in our product inspection room:

Special remind:Silk screen printing UV varnish has w inter formula and summer formula, according to the different temperature and climatic conditions.The difference of the formula is the visosity, summer formula will be much higher than in Winter, in order to meet the screen printing process. If the viscosity is still higher, can use special special diluent dilution.In China, from the month April to October, it will be Winter formula, and the rest month, will produce summer formula. We will meet your actual situation and your requirement to arrange the production.

Using matters and Notes:

1. UV curing machine's UV lamp power is generally 3-8kw/branch, 1-3 high-pressure mercury lamps (wavelength 250-400nm), when curing the conveyor belt is generally 15-55m/min.

2. Get different film thickness and gloss, can choose the appropriate mesh plate, generally 100-160t (250-400 mesh) polyester monofilament screen plate glazing;

3. This product can be used directly or added with UV special diluent to adjust the viscosity. After fully stir, then carried out coating, and sealed well after using.

4. If coated in the dark color ink or substrate (such as black, blue), the varnish should be cured immediately, and the curing time may be extended;

5. After glazing, can clean the screen printing plate thoroughly with ester, alcohol or ketone solvent.

6. UV lamp should be cleaned, checked and changed regularly, guarantee the varnish drying well and completely.

Security issues:

1. After curing, this product is non-toxic and non-irritating, but if skin touched with the liquid, must wash with alkaline soap more than three time within 30 minutes Asap. When clothes touched, should change clothes immediately, avoid skin burn caused by a long time touched.

2. Keep the workplace in good ventilation.

Storage:

1. Should avoid sunlight & high-heat, don’t store with oxide materials. S tore in shady and cool, dry and good ventilation condition’s place.

2. Shelf time are 12 months from date of production.

3. Suggested storage temperature environment is 0 ℃ -35 ℃ ,don’t less than 0 ℃ .

Package:

N.W:20KG/drum or 20KG/Carton with 4 barrels and 5KG/barrel, also can meet special packing specification.