Independent homothermic impermeable heater unit ensure the fast heating up and accurate temperature control.

Both the heating type protein glue (hot) and white latex (cold) can be used individually.

Glue part equips steam proof device which can avoid damp papers stuck with the rollers.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

1710*850*1450mm

-

Weight:

-

265 KG

-

Max. size of hard cover:

-

up to A3 landscape size

Quick Details

-

Type:

-

hard cover book binding machine

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

OEM

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

1710*850*1450mm

-

Weight:

-

265 KG

-

Max. size of hard cover:

-

up to A3 landscape size

Product Description

● Hot melt gluing ● Electric edge folder ● Rolling press ● Automatic adding water ● Vacuum table ● Soft light table

Feature

SK950L is a case making system which features hot-melt gluer, vacuum suction, center position, electric edge folder and rolling press multi-functions in one machine.

It is designed according to the case making process and operating habits, it is suitable for mass production case making of hard cover books, albums, menu books.

● 500mm gluing and pressing width, Max. size of hard cover up to A3 landscape size.

● Copper alloy made Glue application roller and Glue tray. Independent homothermal impermeable heater unit.

● Automatic water replenishing, step-less glue application speed.

● Microthermal animal glue drying quickly, no deformation and lower cost.

● Animal glue and water-based white latex are both available.

● Soft light table with center position.

● Large air quantity suction assistance position.

● Flexible and fast to change the different width of spine guides.

● Antidromic electric edge folding operate.

● Adjustable rolling press pressure.

● Soft rubber roller and steel roller makes the pressure uniform and constant.

● Stack the cover papers and cardboards on the Upper table.

● The base of the machine is equipped with high load bearing Footmaster casters, which is convenient for moving the machine, level adjustment and rising fixed.

SK950L is a case making system which features hot-melt gluer, vacuum suction, center position, electric edge folder and rolling press multi-functions in one machine.

It is designed according to the case making process and operating habits, it is suitable for mass production case making of hard cover books, albums, menu books.

● 500mm gluing and pressing width, Max. size of hard cover up to A3 landscape size.

● Copper alloy made Glue application roller and Glue tray. Independent homothermal impermeable heater unit.

● Automatic water replenishing, step-less glue application speed.

● Microthermal animal glue drying quickly, no deformation and lower cost.

● Animal glue and water-based white latex are both available.

● Soft light table with center position.

● Large air quantity suction assistance position.

● Flexible and fast to change the different width of spine guides.

● Antidromic electric edge folding operate.

● Adjustable rolling press pressure.

● Soft rubber roller and steel roller makes the pressure uniform and constant.

● Stack the cover papers and cardboards on the Upper table.

● The base of the machine is equipped with high load bearing Footmaster casters, which is convenient for moving the machine, level adjustment and rising fixed.

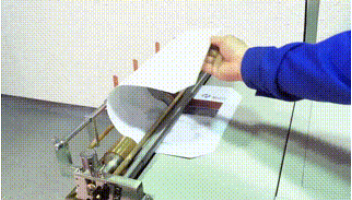

Glue rollers, glue tray and peeling pieces adopt copper alloy which makes heat conduction fast and glue application well-distributed.

Self-adaption peeling pieces strip the glued cover papers from the roller without adjusting.

Self-adaption peeling pieces strip the glued cover papers from the roller without adjusting.

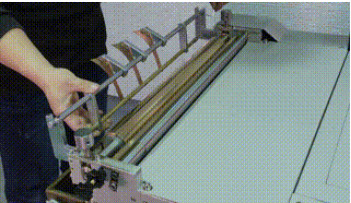

Insert the cardboard into the folder part side by side, all four sides of the cover papers are folded.

Light reflex checking, when the cardboards are turned-in, the machine will start and make the edge folded.

The size and the position of the edge folding can be adjusted.

The edge folding pressure can be adjusted to adapt the different thickness of the cardboard.

Light reflex checking, when the cardboards are turned-in, the machine will start and make the edge folded.

The size and the position of the edge folding can be adjusted.

The edge folding pressure can be adjusted to adapt the different thickness of the cardboard.

Add appropriate water by Automatic water replenishing device according to the glue condition in order to avoid glue becomes dry

and hard

and hard

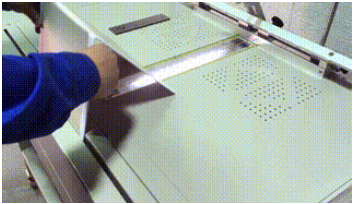

Put the hard cover in the rolling press system, and the hard cover will be formed by proper pressure.

Edge size can be adjusted.

Suction assistance makes the cover material positioned accurately, no removable, which avoid the bubbles when the cover glued with

cardboard.

Soft light table with center positioning makes the spine position easy to view.

cardboard.

Soft light table with center positioning makes the spine position easy to view.

Flexible and fast to change the different width of spine guides, easy to create multiple hard cover books and calendar stands.

It can produce butterfly-fold binding books with simple accessories.

It can produce butterfly-fold binding books with simple accessories.

Size Information

|

Max. size of product

|

A3+ landscape

|

Working table size

|

980x466mm

|

|||

|

Gluing width

|

500mm

|

Rolling width

|

500mm

|

|||

|

Power Supply

|

220V 2800W

|

Machine weight

|

265kg

|

|||

|

Machine dimensions

|

2160x850x1450mm

|

|

|

|||

|

※ Reserve the right to change the parameters without prior notice.

|

|

|

|

|||

Best Selling

Hot Searches