Salesman : Ian Liao

E-Mail

: Ian@fsbanyuan.com

|

Product name

|

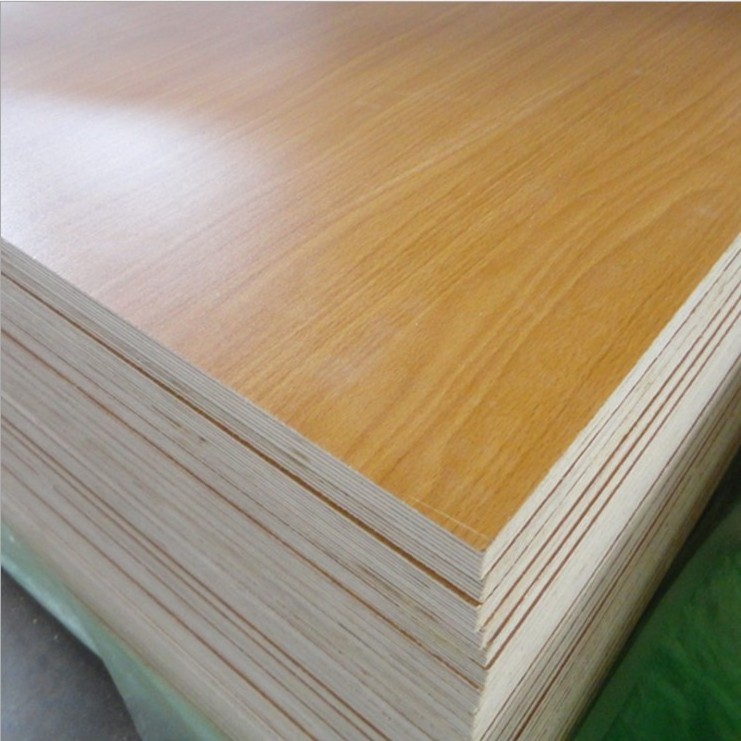

Multiple laminate plywood

Multilayer board Composite board |

|

Feature

|

Moisture-Proof /waterproof /mould proof /anti-bent

|

|

color

|

wood grain /cloth grain /pattern /plain

|

|

Surface Finishing

|

Grain /smooth /matt

|

|

Thickness

|

customizable/

5 /9 /12 /15 /16 /18 /25 /30mm

|

|

|

1220*2440mm/4'*6'

1220*2745*mm/4'*9'

1220*3050*mm/4'*10' 1830*2440*mm/6'*8' 1830*2745*mm/6'*9' 2200*2460*mm/7'*8' 2200*2745*mm/7'*9' 2440*1830mm/4'*8' 2440*1530mm/5'*8' |

|

Grade

|

E1/E2/ F1 F2 /P1 P2

|

|

Type

|

Melamine Plates

|

|

Original place :

|

Foshan city in China

|

|

Embossing texture design

|

60 kinds different embossing including:matt, rough, leather, wove, flower, high gloss,synchronized embossing, crocodile

texture,corrugated texture

|

|

Other panels Type

|

|

|

Decorative layer pattern

|

wooden grain / marble stone /cloth grain /customize parttern

|

|

Interiors Decoration :

|

wall decor /floor decor /wardrobe decor

tables /office furniture /kitchen

|

|

Scenarios :

|

Government office buildings /commercial buildings /sports

centers, airports /hospitals /hotels /banks /schools /clubs / factories /shopping malls /other public space occasions |

|

International Certifications

|

ISO:9001

ISO:14001

SGS/FSC/CE

|