- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ, 380V/50HZ or customized

-

Dimension(L*W*H):

-

L4200 x W2000 x H2900mm

-

Power (kW):

-

45KW

-

Weight (KG):

-

2800 KG

-

Machine type:

-

PU Foam Machine

-

Power:

-

45kw

-

Raw material:

-

isocyanate and polyol(ISO and POLY)

-

Output:

-

10-5000g/s

-

machine type:

-

high pressure

-

foaming agent:

-

cyclopentane

-

Certification:

-

ISO 9001:2015

-

Weight:

-

2800KG

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LINGXIN

-

Machine Type:

-

cyclopentane pu mixing machine

-

Voltage:

-

380V 50HZ, 380V/50HZ or customized

-

Dimension(L*W*H):

-

L4200 x W2000 x H2900mm

-

Power (kW):

-

45KW

-

Weight (KG):

-

2800 KG

-

Machine type:

-

PU Foam Machine

-

Power:

-

45kw

-

Raw material:

-

isocyanate and polyol(ISO and POLY)

-

Output:

-

10-5000g/s

-

machine type:

-

high pressure

-

foaming agent:

-

cyclopentane

-

Certification:

-

ISO 9001:2015

-

Weight:

-

2800KG

-

Marketing Type:

-

Ordinary Product

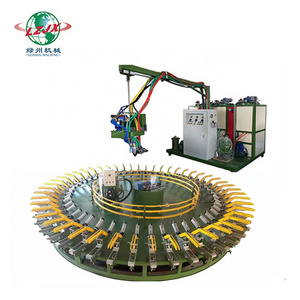

Technical Parameter:

Injection output: 2-5000g/s

Material tank volume: 30L-500L

Mixing ratio range: 100:28~48~150

Mixing head: 2800-5000rpm, forced dynamic mixing

Compressed air needed: dry, oil free, P:0.6-0.8MPa Q:600NL/min(customer-owned)

Nitrogen requirement: P:0.05MPa Q:600NL/min(customer-owned)

Temperature control system: heat:2×3KW

Input power: three-phase five-wire 380V 50HZ Other power customizable

Total power: 35-70kw

Color( customizable): White/Red/Blue

Weight: 2000Kg-2500Kg

Dimension: 4200(L)*2000(W)*2900(H)mm

Equipment Overview:

PU foaming machines have wide application in the market, which have features of economy and convenient operation and maintenance,etc. The machines can be customized according to customers' requirement for various output and mixing ratio.

Main Description :

(1) -- With safety protection by anti riot glass and aluminum alloy arround the machine.

(2) -- There is a draining wind device on the safety cover;with safe wind exhaust system.

(3) -- Have wind pressure switch to ensure the good working of the fans.

(4) -- Cyclopentane gas detector is installed in the enclosure and connects with the control system.

(5) -- With explosion-proof pressure sensor for high and low pressure exchange system.

(6) -- Explosion-proof mixing motors for tank A & explosion-proof deceleration motor for metering pump.

(7) -- Pneumatic components also use explosion-proof type, and have good anti static and grounding measures.

(8) -- Automatic material feeding system is adopted with multi-point monitoring for the material level,avoid overflowing of raw material.

(9) -- Pneumatic controller for nitrogen gas at the mixing head.

Our company: