- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

0

-

Place of Origin:

-

Yunnan, China

-

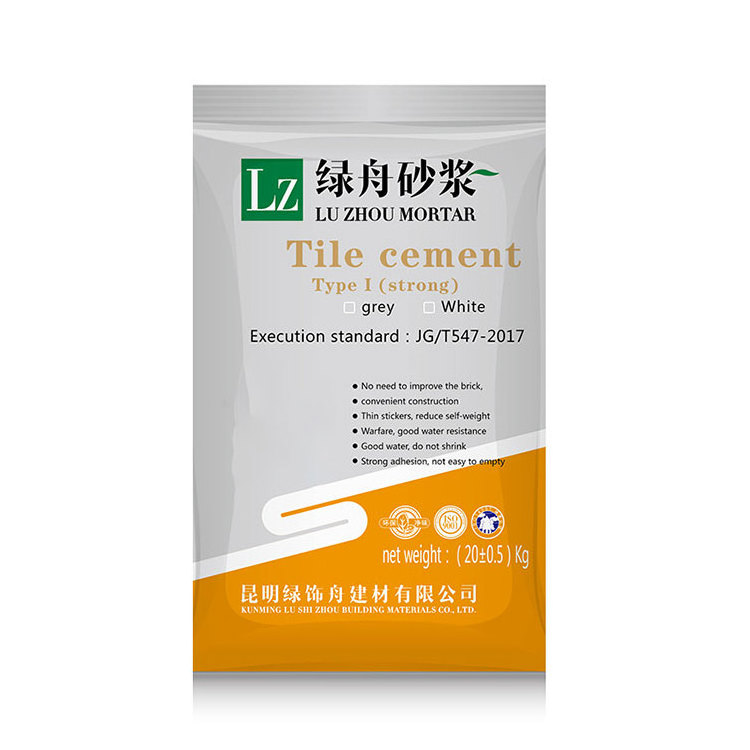

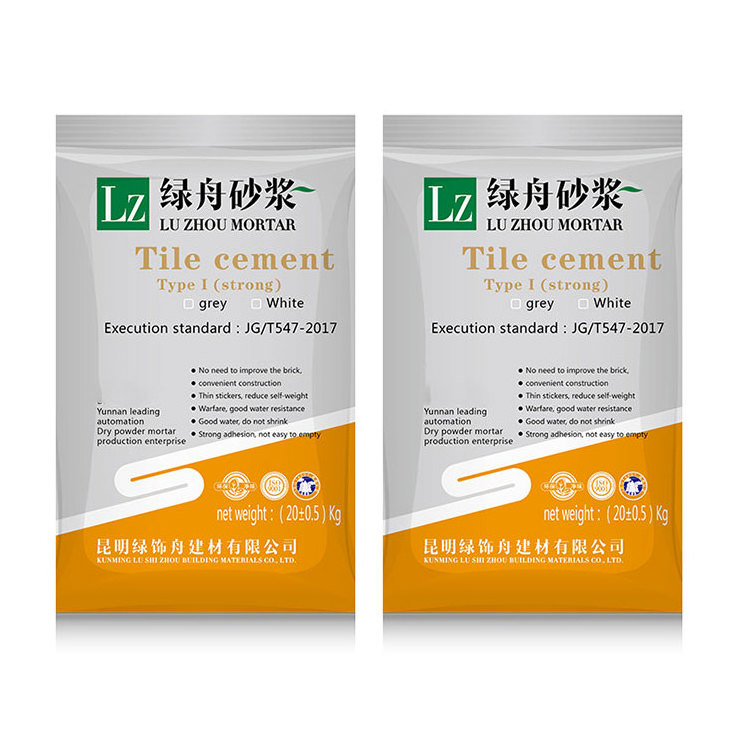

Brand Name:

-

lu zhou mortar

-

Model Number:

-

JG/T547-2017

-

Type:

-

Ceramic tile mastic

-

Product name:

-

Cement Based Strong Tile Glue for Ceramic Tiles and Porcelain

-

Application:

-

for bonding tiles on floor and wall

-

Material:

-

Cement, graded sand, HPMC, special additive

-

Keywords:

-

tile adhesive

-

Feature:

-

Strong Tile Glue

-

Viscosity:

-

Excellent Viscosity

-

Certificate:

-

ISO9001

-

Advantage:

-

free sample

-

Application range:

-

Tile Glue

-

Color:

-

Gray

Quick Details

-

CAS No.:

-

0

-

Other Names:

-

Tiles ceramic tile adhesive cement based tile glue

-

MF:

-

0

-

EINECS No.:

-

0

-

Place of Origin:

-

Yunnan, China

-

Brand Name:

-

lu zhou mortar

-

Model Number:

-

JG/T547-2017

-

Type:

-

Ceramic tile mastic

-

Product name:

-

Cement Based Strong Tile Glue for Ceramic Tiles and Porcelain

-

Application:

-

for bonding tiles on floor and wall

-

Material:

-

Cement, graded sand, HPMC, special additive

-

Keywords:

-

tile adhesive

-

Feature:

-

Strong Tile Glue

-

Viscosity:

-

Excellent Viscosity

-

Certificate:

-

ISO9001

-

Advantage:

-

free sample

-

Application range:

-

Tile Glue

-

Color:

-

Gray

Scope of application

1. It is applicable to ceramic tiles with a high water absorption of 20.6%, and the back surface shows obvious water absorption after dripping, Ordinary ceramic tiles less than 600X 600mm in size.

2. large and medium-sized ceramic tiles are paved on the surface of the cement base.

3. not suitable for outdoor applications.

4. any application beyond the above range, such as the water absorption of the tiles <0.6%, ceramic tiles.

Effective interface treatment must be made on the back, and then strong ceramic tile adhesive shall be used for normal paving.

Product features

Labor saving, easy pasting, high efficiency and economy

Freeze thaw resistance, aging resistance, good permeability resistance, environmental protection, no drinking

Base surface treatment

1. the surface of base course shall be solid, clean, free of hollowing, oil stain, wax stain, release agent andOther loose objects.

2. after the concrete surface is completed and cured for 28 days, it can be paved. The newly plastered surface shall

Pave after less than 7 days of curing.

3. the old concrete and plastered surface can be cleaned with industrial detergent or degreasing agent, and then Rinse with high-pressure tap. The surface can be paved after being dried for 24 hours.

4. under high temperature and dry environment, the base surface shall be wetted before construction.

1. It is applicable to ceramic tiles with a high water absorption of 20.6%, and the back surface shows obvious water absorption after dripping, Ordinary ceramic tiles less than 600X 600mm in size.

2. large and medium-sized ceramic tiles are paved on the surface of the cement base.

3. not suitable for outdoor applications.

4. any application beyond the above range, such as the water absorption of the tiles <0.6%, ceramic tiles.

Effective interface treatment must be made on the back, and then strong ceramic tile adhesive shall be used for normal paving.

Product features

Labor saving, easy pasting, high efficiency and economy

Freeze thaw resistance, aging resistance, good permeability resistance, environmental protection, no drinking

Base surface treatment

1. the surface of base course shall be solid, clean, free of hollowing, oil stain, wax stain, release agent andOther loose objects.

2. after the concrete surface is completed and cured for 28 days, it can be paved. The newly plastered surface shall

Pave after less than 7 days of curing.

3. the old concrete and plastered surface can be cleaned with industrial detergent or degreasing agent, and then Rinse with high-pressure tap. The surface can be paved after being dried for 24 hours.

4. under high temperature and dry environment, the base surface shall be wetted before construction.

usage method

1. The mixing ratio is powder: clean water =20kg: 4.5-5.2kg. Pour the water into the bucket first, Add the powder and stir it evenly to form a paste without powder particles, and then stir it again after standing for 5 minutes Once.

2. it is recommended to use a toothed scraper for construction: first scrape 1m of mastic on the wall, and then After that, use the tooth scraper to evenly scrape the tooth shape mark, and then scrape the glue on the back of the ceramic tile

and use the tooth shape Scrape out the tooth marks with a scraper, and smoothly knead and press the ceramic tiles on the wall scraped by the glue, using rubber, Make sure the hammer is in place.

3 when selecting the size of the tooth shaped scraper, the flatness of the working surface, the size of the ceramic tile and the back Bump degree of the face.

matters needing attention

1. the product can be mixed with water in proportion. It is forbidden to add other materials. This product is made of natural ore As raw materials, the color difference between batches is normal and does not affect normal use.

2. the powder / water ratio can be properly adjusted according to the substrate, weather and construction conditions.

3. the construction in rainy days must be well shielded to ensure that it will not be wet by rain 24 hours after paving.

4. the mixed mortar shall be used up within 2 hours. The dried mortar shall not be reused after mixing with water.

1. The mixing ratio is powder: clean water =20kg: 4.5-5.2kg. Pour the water into the bucket first, Add the powder and stir it evenly to form a paste without powder particles, and then stir it again after standing for 5 minutes Once.

2. it is recommended to use a toothed scraper for construction: first scrape 1m of mastic on the wall, and then After that, use the tooth scraper to evenly scrape the tooth shape mark, and then scrape the glue on the back of the ceramic tile

and use the tooth shape Scrape out the tooth marks with a scraper, and smoothly knead and press the ceramic tiles on the wall scraped by the glue, using rubber, Make sure the hammer is in place.

3 when selecting the size of the tooth shaped scraper, the flatness of the working surface, the size of the ceramic tile and the back Bump degree of the face.

matters needing attention

1. the product can be mixed with water in proportion. It is forbidden to add other materials. This product is made of natural ore As raw materials, the color difference between batches is normal and does not affect normal use.

2. the powder / water ratio can be properly adjusted according to the substrate, weather and construction conditions.

3. the construction in rainy days must be well shielded to ensure that it will not be wet by rain 24 hours after paving.

4. the mixed mortar shall be used up within 2 hours. The dried mortar shall not be reused after mixing with water.

1. who are we?

We are based in Yunnan, China, start from 2022,sell to South Asia(30.00%),Domestic Market(30.00%),Eastern

Asia(20.00%),Oceania(10.00%),Mid East(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Exterior wall putty powder,interior wall putty powder,Ceramic tile adhesive,Self-leveling cement,Anti-cracking putty powder

4. why should you buy from us not from other suppliers?

we have specialized in the production of cement-based exterior wall putty powder series, interior wall putty powder series,

interior wall lining series, tile adhesive series, cement self-leveling series, thermal insulation mortar series.

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW,FCA;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,PayPal;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

We are based in Yunnan, China, start from 2022,sell to South Asia(30.00%),Domestic Market(30.00%),Eastern

Asia(20.00%),Oceania(10.00%),Mid East(10.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Exterior wall putty powder,interior wall putty powder,Ceramic tile adhesive,Self-leveling cement,Anti-cracking putty powder

4. why should you buy from us not from other suppliers?

we have specialized in the production of cement-based exterior wall putty powder series, interior wall putty powder series,

interior wall lining series, tile adhesive series, cement self-leveling series, thermal insulation mortar series.

5. what services can we provide?

Accepted Delivery Terms: FOB,EXW,FCA;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,PayPal;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Hot Searches