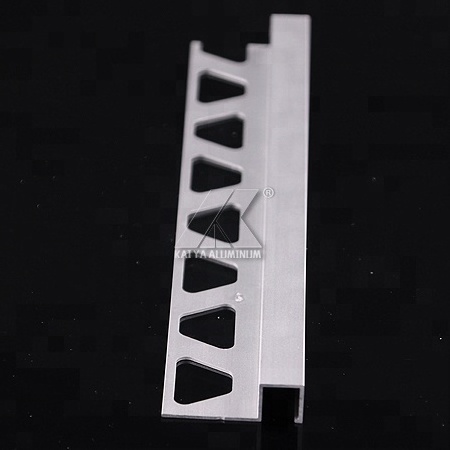

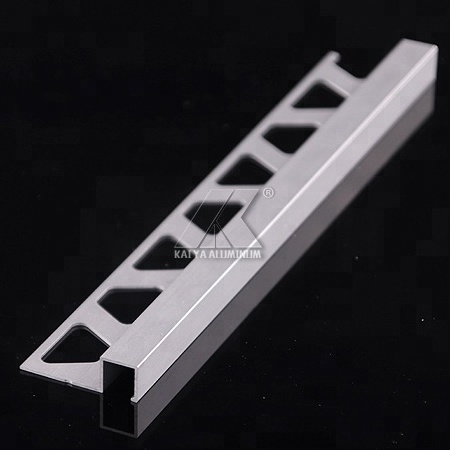

We have

imported

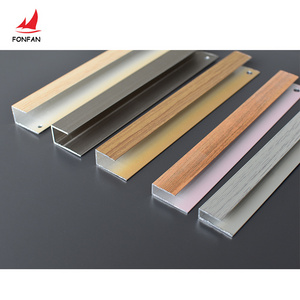

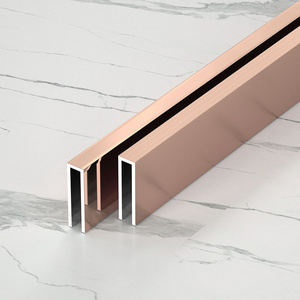

extruder, ice machines, electrophoresis production line, powder coating production line and wood grain

production line from Taiwan, France, Switzerland, Germany, Japan and Italy.

300 staffs with outstanding . passion, responsibility, patience.

300 staffs with outstanding . passion, responsibility, patience.