- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

AZ31, AZ91, AZ61

-

Shape:

-

rod

-

Material:

-

magnesium alloy, Magnesium Alloy

-

Chemical Composition:

-

Mg Al Zn

-

Product name:

-

High quality zinc aluminium magnesium steel sheet in coils price

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Certification:

-

ISO9001:2015

-

Surface treatment:

-

Polishing and satin-finished

-

Color:

-

silver gray

-

Standard:

-

ASTM UNS

-

Packing:

-

Plywood carton

-

Quality Control:

-

100% Inspection

-

Lead Time:

-

15-35 Days

Quick Details

-

Application:

-

Industrial Magnesium Alloy

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Maige

-

Model Number:

-

AZ31, AZ91, AZ61

-

Shape:

-

rod

-

Material:

-

magnesium alloy, Magnesium Alloy

-

Chemical Composition:

-

Mg Al Zn

-

Product name:

-

High quality zinc aluminium magnesium steel sheet in coils price

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Certification:

-

ISO9001:2015

-

Surface treatment:

-

Polishing and satin-finished

-

Color:

-

silver gray

-

Standard:

-

ASTM UNS

-

Packing:

-

Plywood carton

-

Quality Control:

-

100% Inspection

-

Lead Time:

-

15-35 Days

Introduction to magne sium alloys:

Magnesium is the lightest common structural metal with a density of 1.74g/cm3, in its solid state.

Magnesium is used in a wide variety of applications from medical and metallurgical to chemical and pyrotechnic . Magnesium alloy developments have traditionally been driven by aerospace industry requirements for lightweight materials to operate under increasingly demanding conditions. Magnesium alloys have always been attractive to designers due to their low density, only two thirds that of aluminum. This has been a major factor in the widespread use of magnesium alloy castings and wrought products.

A further requirement in recent years has been for superior corrosion performance, and dramatic improvements in this regard have been demonstrated for new magnesium alloys. Improvements in mechanical properties and corrosion resistance have led to greater interest in magnesium alloys for aerospace and other specialized applications, and alloys are now being specified on some famous projects.

The key properties of Magnesium Alloy

1. High strength-to-weight ratio

2. High stiffness-to-weight

3. Castability

4. Machinability

5. Excellent damping

6. Highest electromotive series among metals in salt water.

7. Biocompatibility and bioabsorb ab ility

Designation system of magnesium alloy

1. The ASTM standard alloy designation

2. UNS , it is a complementary syst em of ASTM and the Society of Automotive Engineers (SAE)

Main types of Magnesium Alloys:

(M) Magnesium - manganese

(AM) Magnesium - Aluminum - Manganese

(AZ) Magnesium - Aluminum - Zinc - Manganese

(K) Magnesium - Zirconium

(ZK) Magnesium - Zinc- Zirconium

(ZE) Magnesium - Zinc - Zirconium - with Rare Earth

(EZ) Magnesium - Rare Earth Metal- Zirconium

(QE) Magnesium - Silver - Rare Earth Metal - Zirconium

(WE) Magnesium - Yttrium Rare Earth Metal - Zirconium

(ZC) Magnesium - Zinc - copper - Manganese

(AS) Magnesium - Aluminum - Silicon - Manganese

(AJ) Magnesium - Aluminum - Strontium

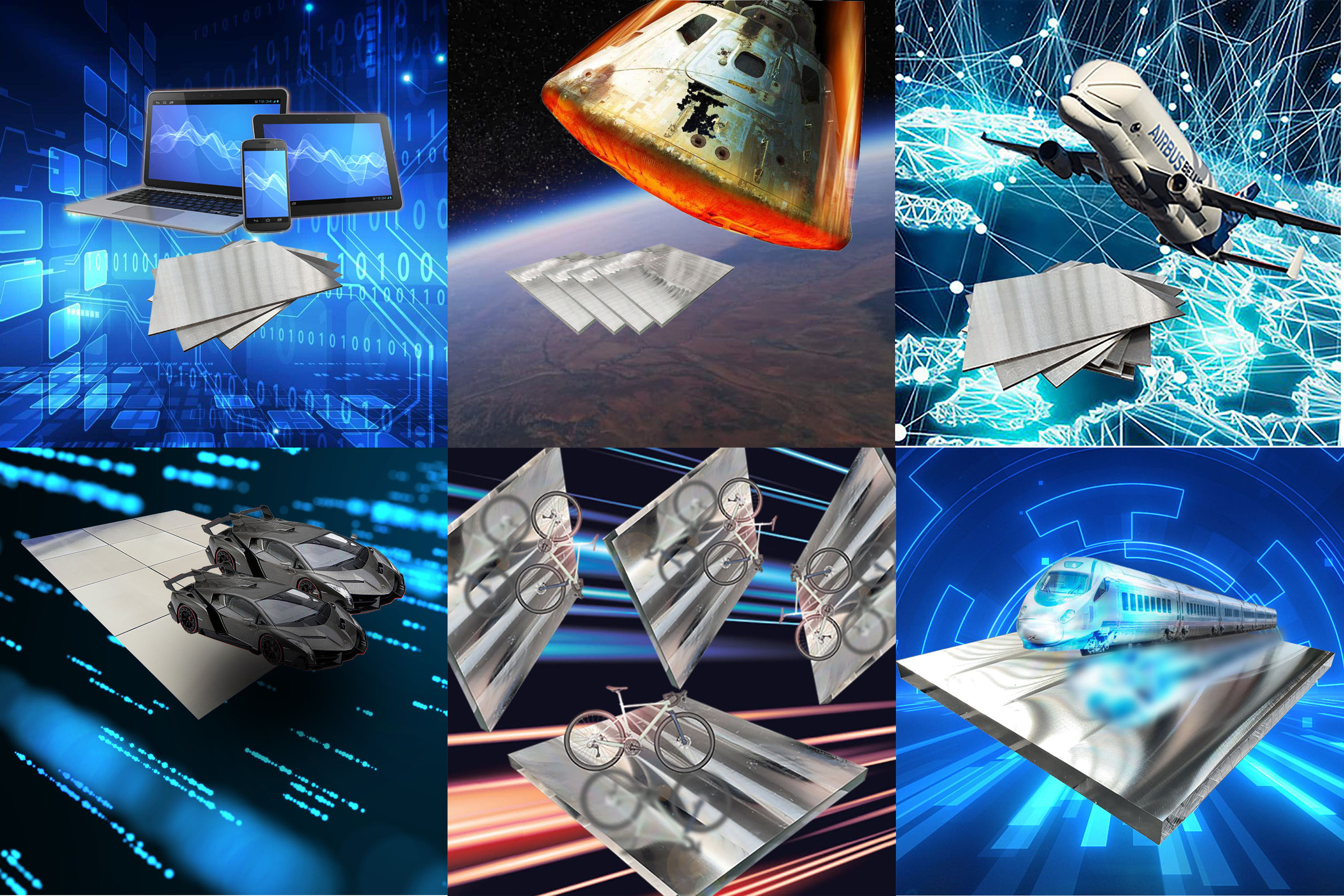

Applications:

Structural:

1. Automotive Industr y :

Clutch and brake pedal support brackets.

Steering column lock housing:

Manual transmission housing.

2. Ind us trial Machinery:

Tex t ile and printing machines. Magnesium alloys are used for parts that operate at high speed but must be lightweight to minimize inertial forces.

3. Material Handling e quipment:

Dockboards, grain shovels, gravity conveyors.

4. Commercial applications:

Handheld tools, Luggage, computer housing, ladders.

5. Aerospace:

Magnesium Alloys are valuable for aerospace application because they are lightweight and exhibit good strength and stiffness at both room and elevated temperatures

6. Bicycle:

Magnesium Alloys are used in the bicycle industry due to its excellent stiffness and reduced weight compared to Aluminum.

Metallurgical:

Magnesium is used as an alloying element in nonferrous alloys. Such as aluminum.zinc, and lead. It is used as an oxygen scavenger in nickle and copper alloys and a desulfurizer in iron and steel production. Magnesium improves the toughness and ductility of cast iron by making the graphite particles nodular. This is the greatest use of magnesium by weight.

Electrochemical Applications.

Magnesium is used as an alloying element in nonferrous alloys. Such as aluminum.zinc, and lead. It is used as an oxygen scavenger in nickle and copper alloys and a desulfurizer in iron and steel production. Magnesium improves the toughness and ductility of cast iron by making the graphite particles nodular. This is the greatest use of magnesium by weight.

Medical Applications:

Magnesium alloys are used in portable medical equipment where light weight is advantages. It is also employed for wheelchairs used in sporting activities(where every ounce is critical). Because of magnesium’s biocompatibility and bioabsorbability, alloys with other biocompatible elements(such as calcium) are being evaluated for cardiovascular stents and orthopedic devices for internal bone fixation.

1. Packing: Plywood carton or corrugated cartons.

All the packing with wetproof treatment.

The logo can be printed as clients requirements.

2. Shipping: Bulk, Container, partial shipment.

1. Providing basing magnesium m a terials. 99.95 Pure magnesium, magnesium alloy sections, like magne s ium alloy Rods, Bars, Wires, tubes, plates, sheets.

2. Die casting magnesium parts, CNC Machining magnesium alloy parts.

3. Custom i zing service of basing magnesium alloys : The dimension and size can make and cut accord to clients '

requirements

Die casting parts and CNC Machining Parts: Due to drawings of customers , OEM , ODM