- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V 50HZ

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

5150mm*1300mm*1920mm

-

Weight:

-

2500 kg

-

Marketing Type:

-

Hot Product 2022

-

Name:

-

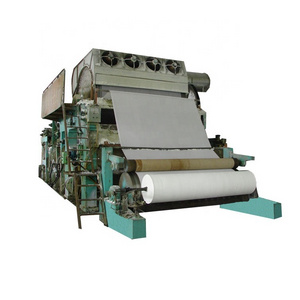

Facial Tissue Paper Making Machine

-

Finished Products:

-

Facial Paper

-

Working speed:

-

120-150m/min

-

Control system:

-

Frequency Converter Control System

-

Paper broken:

-

Photoelectric eye,automatic stop

-

Upper blade:

-

Pneumatic spiral blade

-

Embossing rollers:

-

Steel rolls to woolen rolls

-

Finished size:

-

140*140mm-200*200mm (Customized)

-

Raw paper diameter:

-

Max 1200mm

-

Certification:

-

ISO/CE/TUV

Quick Details

-

Production Capacity:

-

150m/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fuyuan

-

Voltage:

-

220V/380V 50HZ

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

5150mm*1300mm*1920mm

-

Weight:

-

2500 kg

-

Marketing Type:

-

Hot Product 2022

-

Name:

-

Facial Tissue Paper Making Machine

-

Finished Products:

-

Facial Paper

-

Working speed:

-

120-150m/min

-

Control system:

-

Frequency Converter Control System

-

Paper broken:

-

Photoelectric eye,automatic stop

-

Upper blade:

-

Pneumatic spiral blade

-

Embossing rollers:

-

Steel rolls to woolen rolls

-

Finished size:

-

140*140mm-200*200mm (Customized)

-

Raw paper diameter:

-

Max 1200mm

-

Certification:

-

ISO/CE/TUV

Products Description

Production Process

Function & Parameter

1. The machine can equipped with PLC. (need to order)

2.Count automatically and output in order

3. Adopting screw turning knife to cut and vacuum absorption to fold.

4.This equipment can have embossing unit.

5.Design the machine with 2lines, 3 lines ,4 lines, 5 lines and 6 lines according to customers' requirement.

6.Adopts folding pattern through vacuum absorption together with manipulator, which

possesses auto stop when paper breaks, auto electronic counting and pneumatic

staggering function, thus facilitate to separate the designated quantity of tissue for next

step if packaging.

7.Optional items: Electromagnetic speed-regulator, color printing or laminating units.

Machine Parameter

|

Machine Model

|

FY-2L/3L/4L/5L/6L/7L

|

|

|

|

|||

|

Product Size

|

200*200mm (Other Size are Available)

|

|

|

|

|||

|

Paper Diameter

|

φ1300mm(Other Size are Available)

|

|

|

|

|||

|

Paper Core Inner Dia

|

φ76.2mm(Other Size are Available)

|

|

|

|

|||

|

Production Speed

|

0-180m/min

|

|

|

|

|||

|

Voltage

|

220/380V

|

|

|

|

|||

|

Vacuum System

|

7.5KW/11KW/15KW

|

|

|

|

|||

|

Host Power

|

3KW/5.5KW/7.5KW

|

|

|

|

|||

|

Controller

|

Electromagnetic Speed

|

|

|

|

|||

|

Embossing

|

Steel to Steel, Steel to Plastic

|

|

|

|

|||

|

Embossing Roller End

|

Felt Roller, Wool Roller, Rubber Roller, Steel Roller

|

|

|

|

|||

|

Blank Lines

|

Steel on Steel,The Independent Regulator

|

|

|

|

|||

|

Cutting System

|

Pneumatic Point Cut, Full-cut

|

|

|

|

|||

|

Broken Way

|

Face knife

|

|

|

|

|||

|

Dimensions

|

5150mm*1300mm*1920mm (According to the actual model)

|

|

|

|

|||

|

Machine Weight

|

2500kg-4500kg

|

|

|

|

|||

|

Whole Structure

|

The form of wallboard and other structure

|

|

|

|

|||

|

Folding roll gap

|

Adjustable gap between folding rollers

|

|

|

|

|||

|

Use of Power

|

Frequency Control,Electromagnetic Speed

|

|

|

|

|||

|

Trimming System

|

Vacuum trimming and adsorption system

|

|

|

|

|||

Details Display

A variety of embossing styles are available for customers to choose from. We can also customize embossing patterns according to customers' requirements.

Recommend product

Why Choose Us

Our Mission

To provide a more cost efficient solution for our customers.Suitable is the best way.Best for customers, for local market and even for our future. We treat it as our responsibility in every business.

Our Goal

To get trust from every customers who contacted with us. To show our sincerely in communication and our professional skills in business, to provide the most suitable machines for them to satisfy with their special need.

Our Culture

To be professional and progress together. We treat every staffs as a family member.We learned, shared and worked together to reach our goals. A little change everyday makes a big difference someday.

Packing & Delivery

Packaging

1. Fixed all the movable parts with plastic films.

2. Polystyrene foam plate wrapped around.

3. Wrapped with tight plastic films several circles.

4. Fixed machine on the fumigated plywood pallet with iron wire.

5. Wrapped with wooden board around and nailed on.

Shipment

1.Sea transportation is from Qingdao port or other ports.

2.The delivery time is decided by your needed machines or machine parts. But it also follows your needs.

Hot Searches