- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Zhejiang, China

-

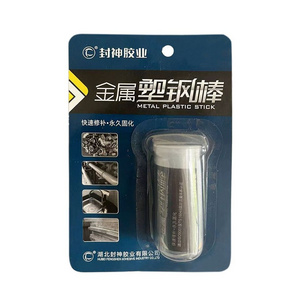

Brand Name:

-

Visbella

-

Model Number:

-

EQ0025BK3P-bdd2

-

Type:

-

Epoxy Putty

-

Components rate:

-

A:B=1:1

-

Application:

-

Metal, Plastic, Wood, Ceramic etc.

-

Curing time:

-

10 mins (25°C mix glue,3-8g)

-

Shear Strength:

-

≥10MPa (25℃*48h,Steel-Steel)

-

Color:

-

Black+White, White+White

-

Sample:

-

Available

-

Packing:

-

Blister Card

-

Certificate:

-

RoHs, REACH, BSCI, ISO9001

-

OEM Packing:

-

Available

-

Shelf life:

-

12-18 Months

Quick Details

-

CAS No.:

-

7085-85-0

-

Other Names:

-

Epoxy Resin

-

MF:

-

Mixture

-

EINECS No.:

-

230-391-5

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Visbella

-

Model Number:

-

EQ0025BK3P-bdd2

-

Type:

-

Epoxy Putty

-

Components rate:

-

A:B=1:1

-

Application:

-

Metal, Plastic, Wood, Ceramic etc.

-

Curing time:

-

10 mins (25°C mix glue,3-8g)

-

Shear Strength:

-

≥10MPa (25℃*48h,Steel-Steel)

-

Color:

-

Black+White, White+White

-

Sample:

-

Available

-

Packing:

-

Blister Card

-

Certificate:

-

RoHs, REACH, BSCI, ISO9001

-

OEM Packing:

-

Available

-

Shelf life:

-

12-18 Months

Visbella ® Epoxy Putty is an hand-mixable and fast setting two part adhesive which are mixed by kneading.It is windely used in daily repair, machinery equipment and can bond, fill and rebuild with excellent bond strength. it does not shrink and it resistant to most common solvents. This putty can also be sanded, drilled and painted.

SAFETY PRECAUTIONS

Wear gloves and wash hands after use.

PREPARATION

Surfaces should be clean and free from grease and oil. Slightly roughen the surface with a wire brush or sandpaper. Cut off desired length of Automotive Epoxy Putty and knead until uniform color is obtained.Putty turns a grey when completely mixed.

APPLICATION

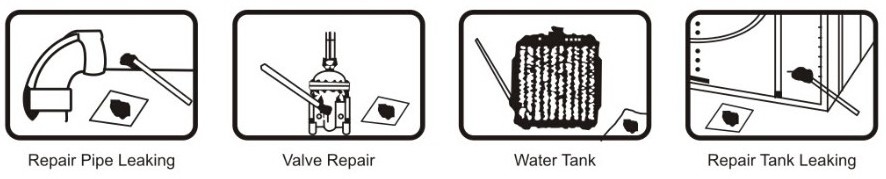

Bonding metal,glass,ceramic,wood,many rigid plastics,china,tile,fiberglass,concrete and stone.

Can be combined with fiberglass cloth for a durable patch.

Apply the putty within 2minutes of mixing,working it firmly into the crack or hole. For bonding, place the putty between the surfaces and apply firm pressure to ensure intimate contact with both surfaces. For a smooth finish, rub the putty with a damp cloth prior to hardening.

Working time is approximately 3 minutes. After 5 to 10 minutes the putty will harden and form a tenacious bond. After 60 minutes, the puttty can be sanded, drilled or painted.

Recommended For:

Bonding metal, glass, ceramic, wood, many rigid plastics, china, tile, fiberglass,concrete and stone. Can be combined with fiberglass cloth for a durable patch.

Not Recommended For:

Polyethylene, polypropylene, Nylon,Teflon or flexible materials.

Applying at temperatures above 120°F (49°C)

Continuously wet areas or water immersion

CLEAN UP

Cured putty may be cut away with cautin using a sharp blade.

ADVANTAGES & FEATURES

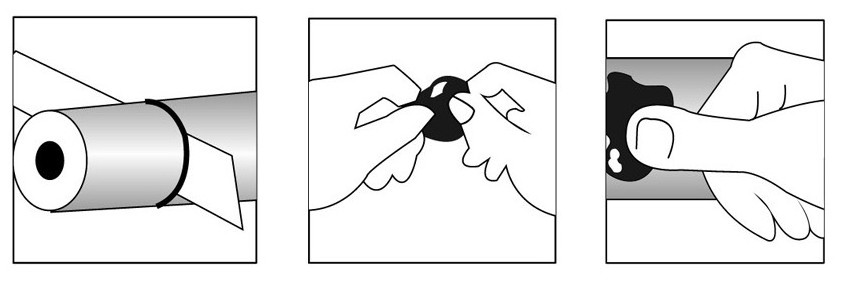

STEP 1 Cut: Cut off a piece of epoxy putty that is large enough to complete the repair.

STEP 2 Mix: Using moist hands, carefully and thoroughly knead the two-component putty together to a uniform color.

STEP 3 Apply: Press putty firmly onto target area. If necessary, secure the putty using a clamp or similar device for 15-20 minutes. Epoxy Putty will harden in 1 hour and will reach full strength in 24 hours.