- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Suction Feeding Machine

-

Product Name:

-

powder dumping station

-

Key Words:

-

manual bag dumping station

-

Material:

-

304 stsainless steel

-

Capacity:

-

400L, 1500L

-

Certification:

-

CE ISO

-

Plate thickness:

-

2mm

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

810

-

Marketing Type:

-

powder feeding station

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Suction Feeding Machine

-

Product Name:

-

powder dumping station

-

Key Words:

-

manual bag dumping station

-

Material:

-

304 stsainless steel

-

Capacity:

-

400L, 1500L

-

Certification:

-

CE ISO

-

Plate thickness:

-

2mm

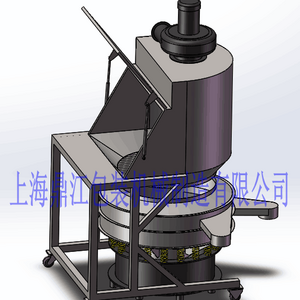

| Model parameter table | |||

| Model | LSGC-SCTLC | LSGC-GX-TL1FA | LSGC-GX-TL1FB |

| Capacity(L) | 400 | 1500 | 1500 |

| Plate thickness(mm) | 2 | 2 | 2 |

| Size(mm) | 730*830*1538 | 2430*2220*1100 | 2430*2220*1100 |

| Suction device output | 3-5t/h | 3-5t/h | |

| Material | SUS304 | SUS304 | SUS304 |

| Color | body matte silver white | body matte silver white | body matte silver white |

| Including | with cover seal and latch, magnetic frame, level switch alarm | Including: cover plate sealing strip and latch, material level switch alarm, material suction device | Including: with cover seal and latch, magnetic frame, level switch alarm, suction device |

| Remark | Manual dumping, air spring lift type upper cover, dust collector connection port | Manual dumping, air spring lift type upper cover, dust collector connection port | Manual dumping, air spring lift type upper cover, dust collector connection port |

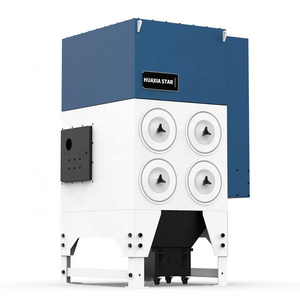

Features:

- Simple structure, convenient operation and easy maintenance;

- It can realize unpacking in an airtight space for feeding and pipeline conveying;

- It can realize online cleaning without dead angle for cleaning;

- Automatic dust collection design to avoid flying dust and improve the working environment;

- Scale style, suitable for different environmental and factory requirements.

Working principle:

- The operator puts a bag of material on the feeding table and pushes it into the grid. Then the operator cuts a vertical opening in the material bag, and dumps and shakes the material bag to empty it; the material falls into the hopper by power, and is effectively conveyed to the designated position through the conveying pipe at the bottom connected to the conveying unit;The built-in induced air dust collection filter can collect the dust generated in the process of emptying the material bag.

- For large feeding stations, ton bags can be unloaded and conveyed to the feeding station through the ton bag unpacking station, and the operator only needs to untie the rope at the mouth of the ton bag to realize automatic feeding.

Scope of application:

- Currently, there are a variety of models, with the feeding capacity of 100L-5,000L, which can meet different customer needs;

- It can be widely used in all industries involving powder, such as rubber and plastics, food, chemicals and batteries.

Hot Searches