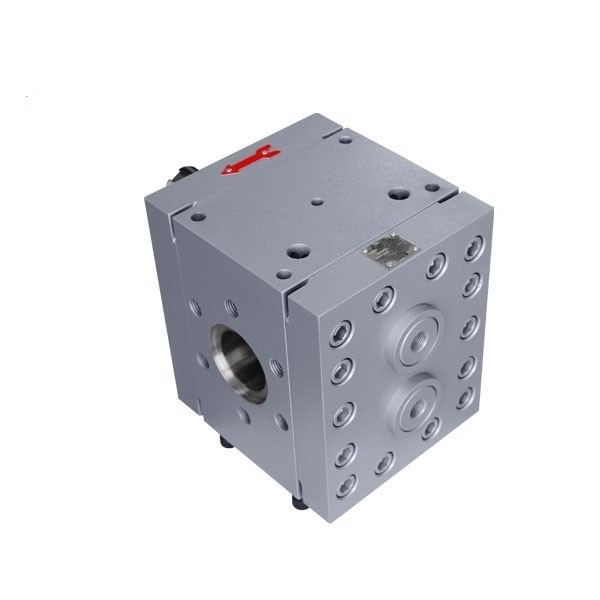

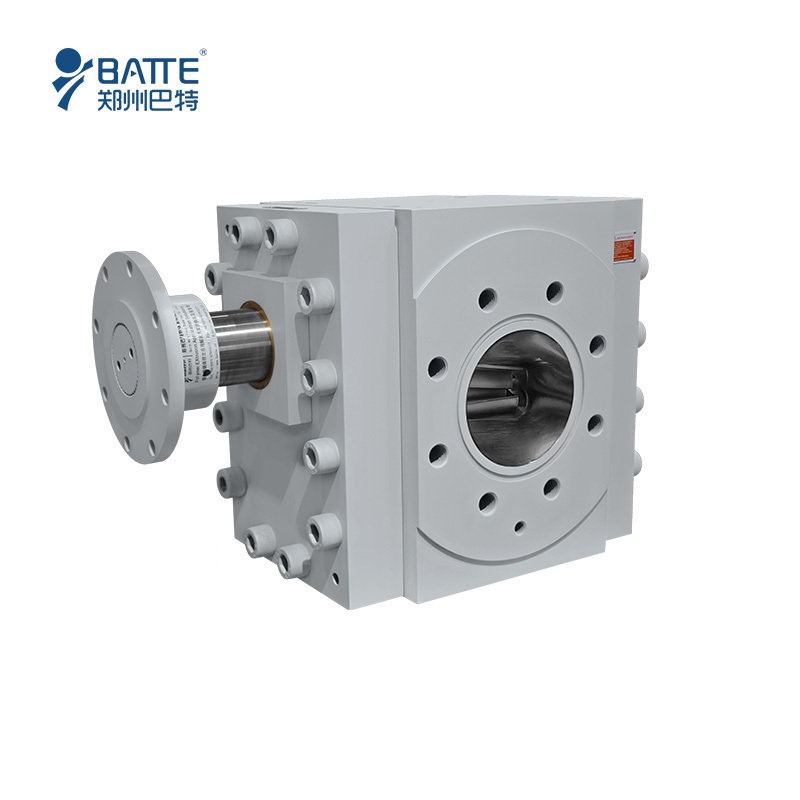

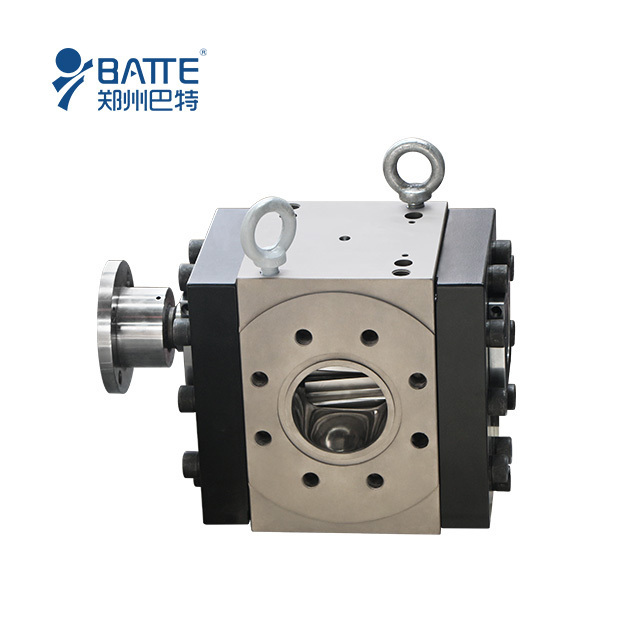

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

batte

-

Place of Origin:

-

Henan, China

-

Product name:

-

rotary gear pump

-

Volume Range:

-

0.5CC - 3200CC

-

Viscosity:

-

≤40000 Pas

-

Working Temperature:

-

≤400°C (750°F)

-

Cleaning Temperature:

-

≤450°C (850°F)

-

Outlet Pressure:

-

40MPa(6000psi)

-

Differential Pressure:

-

≤25Mpa

-

Gear material:

-

M2 Steel

-

Heating System:

-

Electrical Heating

-

Power:

-

BASED ON CAPACITY

Quick Details

-

Application:

-

Plastic extrusion production line

-

Pressure:

-

High Pressure

-

Warranty:

-

1 year

-

Brand Name:

-

batte

-

Place of Origin:

-

Henan, China

-

Product name:

-

rotary gear pump

-

Volume Range:

-

0.5CC - 3200CC

-

Viscosity:

-

≤40000 Pas

-

Working Temperature:

-

≤400°C (750°F)

-

Cleaning Temperature:

-

≤450°C (850°F)

-

Outlet Pressure:

-

40MPa(6000psi)

-

Differential Pressure:

-

≤25Mpa

-

Gear material:

-

M2 Steel

-

Heating System:

-

Electrical Heating

-

Power:

-

BASED ON CAPACITY

Products Description

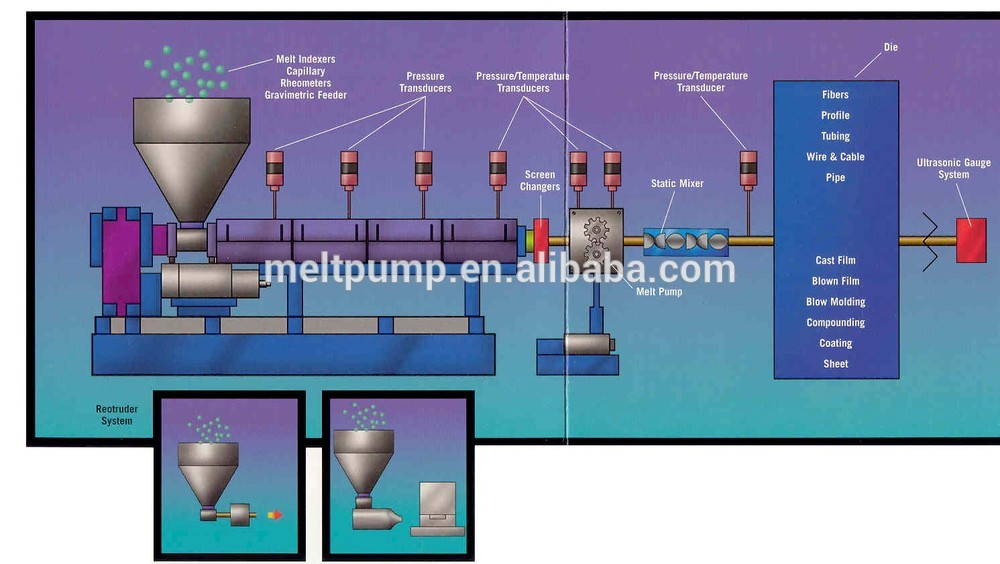

Batte zb-c melt pump is mainly used for metering, transfer and pressure boosting of low or high viscosity polymer melt. The pump parts can be selected to counteract abrasion and conform to various materials characteristics of the pumped media.

Batte hot melt glue pump can be applied in the Scope of Field as follows:

Technical polymers, e. g. PET, PBT, PA, PC, PB

Styrene polymers, e. g. GP-PS HI-PS, ABS, SAN, SB

Acrylic polymers, e. g. PMMA

Polyolefins , e. g. PP, PE

Bio polymers, e. g. PLA

Elastomers, e. g. PUR, TPE, TPU

High temperature thermoplastics, e. g. PEEK, PAI, PAEK, PSU, PI, LCP

Expandable polymers e. g. EPS, EPP

Special polymers, e. g. EVA, EVOH

Polymers with fillers and recycling materials

Styrene polymers, e. g. GP-PS HI-PS, ABS, SAN, SB

Acrylic polymers, e. g. PMMA

Polyolefins , e. g. PP, PE

Bio polymers, e. g. PLA

Elastomers, e. g. PUR, TPE, TPU

High temperature thermoplastics, e. g. PEEK, PAI, PAEK, PSU, PI, LCP

Expandable polymers e. g. EPS, EPP

Special polymers, e. g. EVA, EVOH

Polymers with fillers and recycling materials

Working Principles of BATTE hot melt glue pump (ZB-C Series):

This type of extrusion melt pump is mainly used in conjunction with extruders or kneaders. It reduces the natural pulsation and irregular conveyance, particularly in single-screw extruders, added to which, the build up of pressure in the gear pump is more efficient in comparison to the extruder. Because of this, less energy or heat is transferred into the polymer and the product is conveyed in a gentler manner. This type of extrusion melt pump is indispensable for the manufacture of precision films or micro granulate.

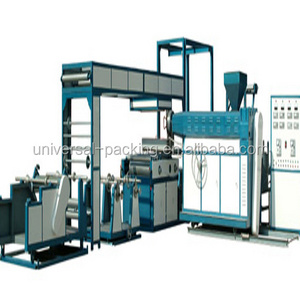

One Whole Set of BATTE hot melt glue pump (ZB-C Series) Comprise :

1. Melt Pump

2. Driven System: Motor + Reducer

3. Control System: PLC Touchscreen System

2. Driven System: Motor + Reducer

3. Control System: PLC Touchscreen System

The Performance Advantage of BATTE hot melt glue pump (ZB-CSeries):

1. Reducing stress on the extruder by means of shifting the job of building pressure to the melt pump;

2. Increasing the hourly output;

3. Removing the output variations and pressure pulsations, thus greatly improving the product quality;

4. Saving raw material by means of tighter manufacturing tolerances;

5. Improving the the dimensional accuracy during the production of sheets and profiles;

6. Optimizing the surface and optical quality during the production of films, sheets and profiles;

7. Improving the product quality with regard to homogeneity and pellet size in compounding;

8. Extending the lifetime of the upstream machinery;

2. Increasing the hourly output;

3. Removing the output variations and pressure pulsations, thus greatly improving the product quality;

4. Saving raw material by means of tighter manufacturing tolerances;

5. Improving the the dimensional accuracy during the production of sheets and profiles;

6. Optimizing the surface and optical quality during the production of films, sheets and profiles;

7. Improving the product quality with regard to homogeneity and pellet size in compounding;

8. Extending the lifetime of the upstream machinery;

|

Type

|

CC/Rev

|

Capacity (L/H)

|

Heating power (kw)

|

Dirven system (kw)

|

Pressure

|

Temperature

|

|

ZB-0.2

|

0.2

|

0.2-0.6

|

0.5

|

0.37

|

Inlet pressure:≥0Mpa

Exit pressure: ≤35Mpa |

Operating temperature:≤350℃

Clearing temperature:≤450℃ |

|

ZB-1

|

1

|

1-3

|

1

|

0.5

|

|

|

|

ZB-2

|

2

|

2-6

|

1

|

0.75

|

|

|

|

ZB-5

|

5

|

5-15

|

1

|

1.1

|

|

|

|

ZB-10

|

10

|

10-30

|

1

|

1.5

|

|

|

|

ZB-20

|

20

|

20-60

|

2

|

2.2

|

|

|

|

ZB-31.5

|

31.5

|

30-90

|

2

|

3

|

|

|

|

ZB-50

|

50

|

50-150

|

2

|

4

|

|

|

|

ZB-100

|

100

|

100-300

|

3

|

5.5

|

|

|

|

ZB-150

|

150

|

150-450

|

4

|

7.5

|

|

|

|

ZB-200

|

200

|

200-600

|

4

|

11

|

|

|

|

ZB-250

|

250

|

250-750

|

5

|

15

|

|

|

|

ZB-315

|

315

|

300-900

|

6

|

18.5

|

|

|

|

ZB-400

|

400

|

400-1200

|

8

|

22

|

|

|

|

ZB-500

|

500

|

500-1500

|

10

|

30

|

|

|

|

ZB-630

|

630

|

600-1800

|

12

|

37

|

|

|

|

ZB-800

|

800

|

800-2400

|

15

|

45

|

|

|

|

ZB-1000

|

1000

|

1000-3000

|

18

|

55

|

|

|

|

ZB-1500

|

1500

|

1200-4500

|

20

|

75

|

|

|

Certifications

What are the benifits of melt pump on extruder?

What are the benifits of screen changer on extruder?

1, improve the quality of the final products

2,greatly improve the plasticizing of the raw material

3, make the product structure more homogeneous and product surface smoothness

4, protect the down stream equipments, such as Gmach melt pumps and the extrusion dies

What are the benifits of melt pump on extruder?

1, to improve the stability of the product size

2,melting quality control

3, increase output

4, reduce the raw materil consumption

5, improve the flexible of the extruder

6, protect the extrusion die ,extend the service life of the extruder

What are the benifits of installation the screen changer and melt gear pump together?

1, improve the melt plasticaction

2, improve the quality of the products

3, extend the service life of the extruder

4, greatly increase the output of the products

5, reduce the labor interference

6, reduce the unqualified products

What do we need to pay attention when using the screen changer nad melt pump?

1, we should operate the screen changer and melt gear pump as the safety manual, prevent an electrical shock

2, To prevent ourself scald

3, do not disassemble the screen changer and the melt gear pump, any questions, please contact with the supplier.

Exhibition

Installation of Our Melt Pump

The Installation of Our Melt Pump

Installation Method: Motor+Reducer+Universal Coupling+Melt Pump You can use control or direct current governor for the motor, and can adjust the flow to your demands optionally. Please well check our installation method below:

Hot Searches