- Product Details

- {{item.text}}

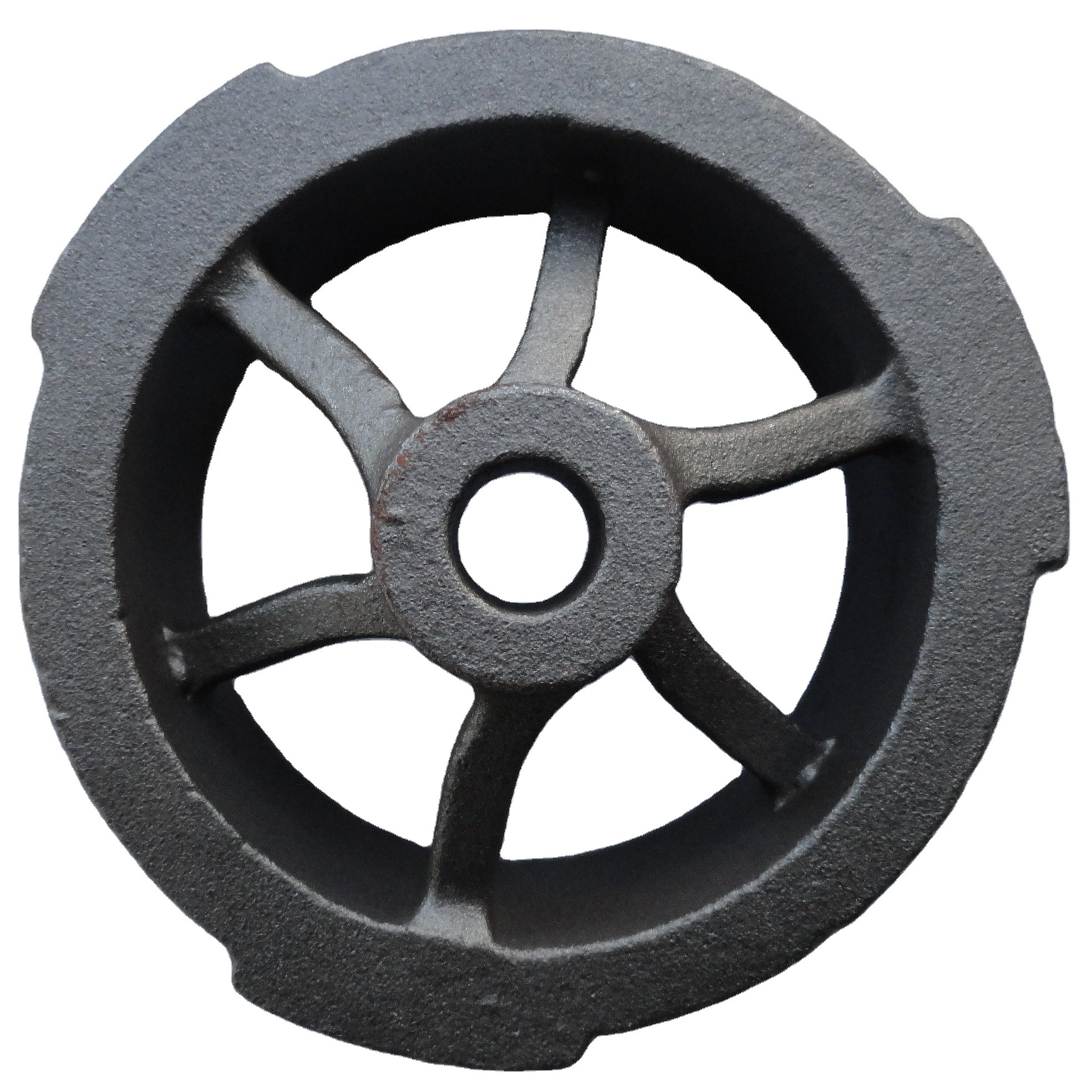

Quick Details

-

Material:

-

Steel

-

Surface treatment:

-

Polishing

-

Application:

-

Machinery Parts

-

Product name:

-

Custom Casting Parts

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

OEM Serivice

-

Certification:

-

ISO9001

-

Dimensions:

-

Customized Sizes

-

Tolerance:

-

0.01-0.05mm

-

Quality Control:

-

IQC

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Huading

-

Model Number:

-

hd031605

-

Material:

-

Steel

-

Surface treatment:

-

Polishing

-

Application:

-

Machinery Parts

-

Product name:

-

Custom Casting Parts

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

OEM Serivice

-

Certification:

-

ISO9001

-

Dimensions:

-

Customized Sizes

-

Tolerance:

-

0.01-0.05mm

-

Quality Control:

-

IQC

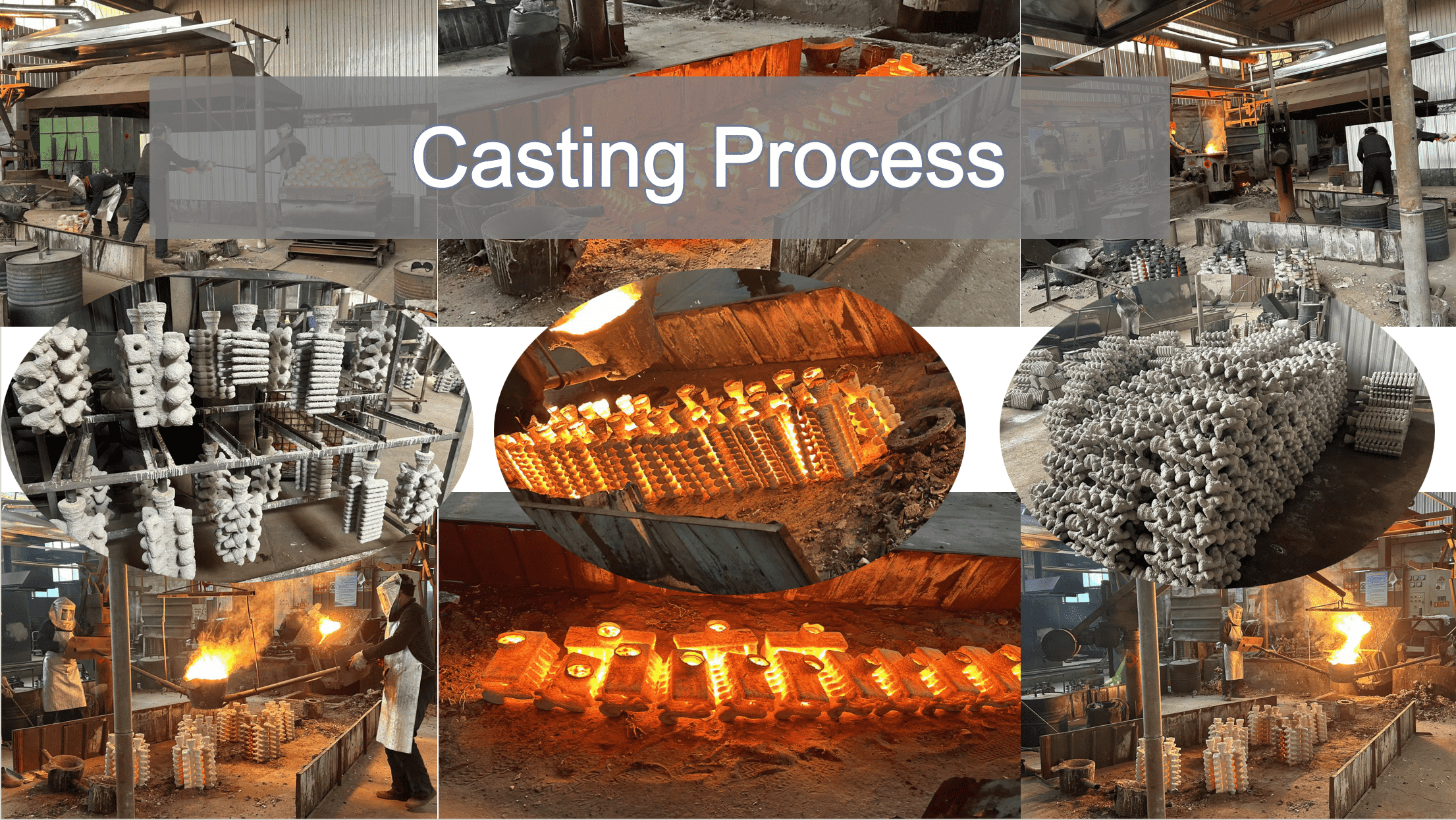

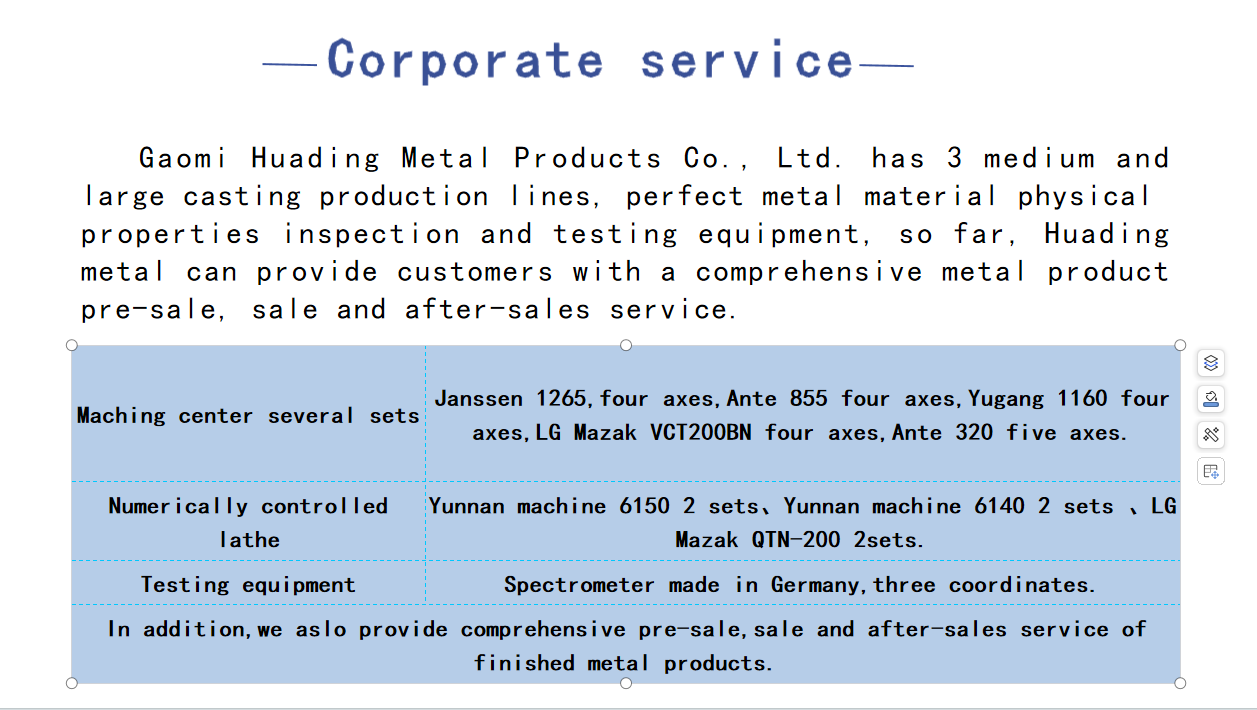

Gaomi Huading Metal Products Co., LTD., founded in 1996, is a modern production enterprise integrating scientific research, casting production and processing. It was renamed from Gaomi Jeli Machinery Technology Co., LTD., the company has been committed to the design, development, production, sales and after-sales service of mechanical parts.

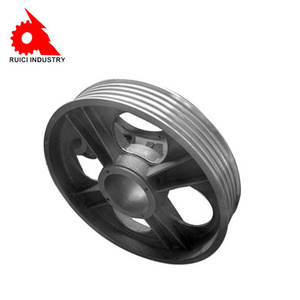

1.Product Name:China high quality investment casting auto machinery parts.

| Material | Carbon steel,Alloy steel,Stainless steel,Aluminium,Copper |

| Process | Lost wax casting/Silica sol+CNC machining |

| Casting tolerance | ISO 2768-mK,VDG P690 D1-D2,ISO8062-3-2007 DCTG4-6,GCTG4-6 |

| Casting roughness | Re1.6-3.2 |

| Machining roughness | Re0.8-3.2 |

| Casting weight range | 0.005-50kg |

| Materal standard | GB,ASTM,DIN,BS,JIS,NF,AS,AAR.... |

| Surface treatment | Zine plating,Polishing,Anodizing,Painting,Nickel plating |

| Heat treatment | Annealing,Normalizing,Harding,Tempering,Case hardening.... |

| Service | OEM&ODM |

| Quality Contral | IATF16949:2016,ISO14001:2015,ISO9001 |

| Application | Auto parts |

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)